High-pressure plunger pump skid-mounting device for oilfield water injection

A technology of high-pressure plunger pump and oil field water injection, which is applied to the parts, pump components, pump control and other directions of the pumping device used for elastic fluid, and can solve the problems of large consumables, difficult disassembly, and long construction period of the prefabricated house. Achieve real-time monitoring of pipeline temperature and pressure, high risk sensitivity, and reduce construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

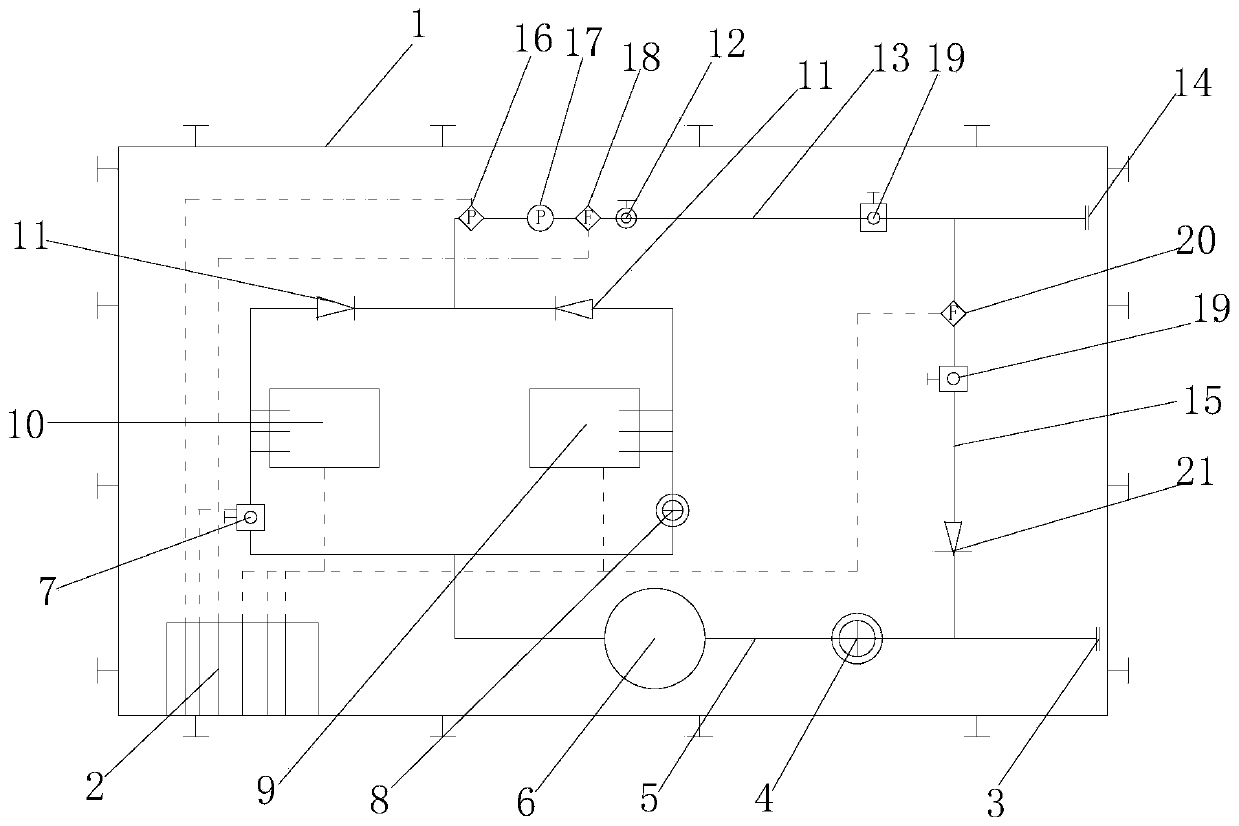

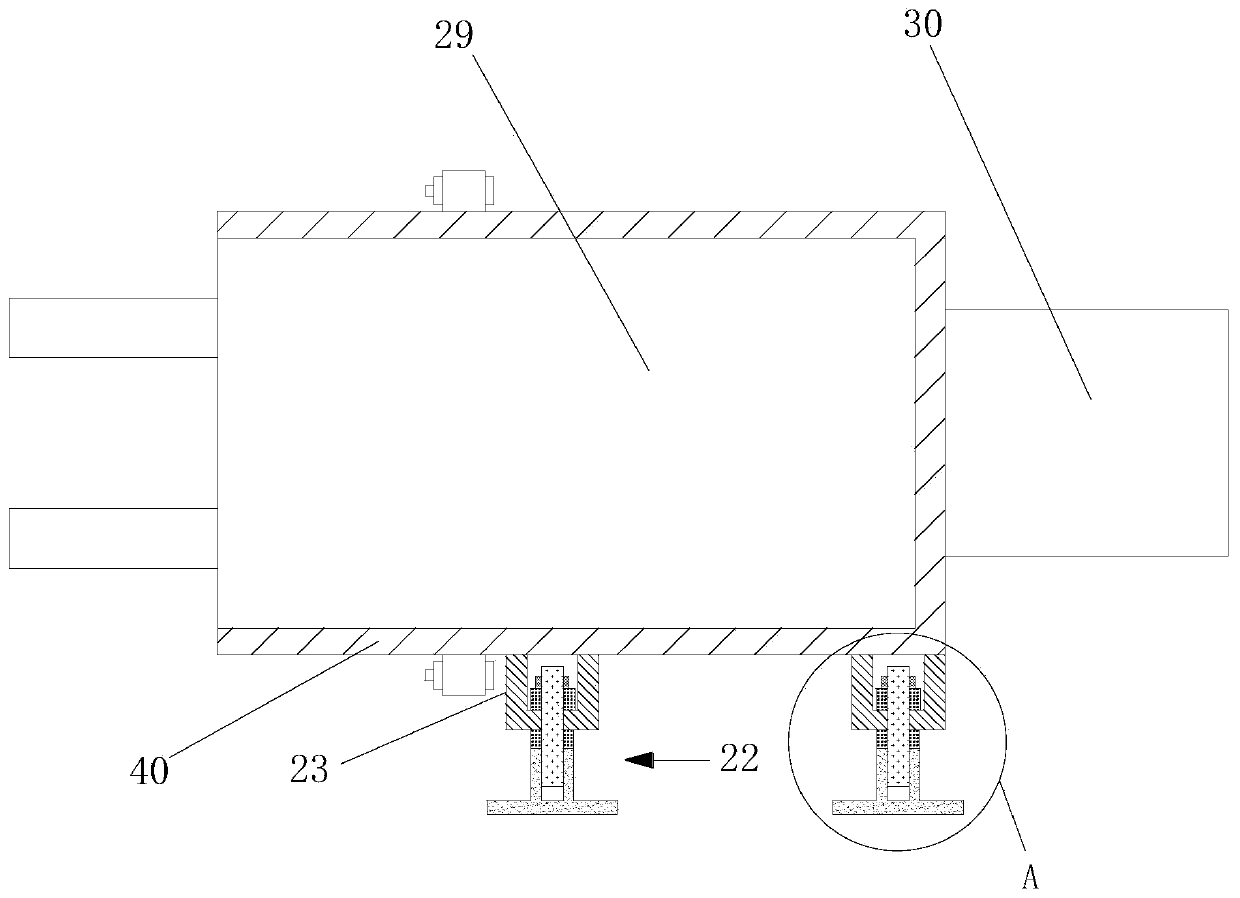

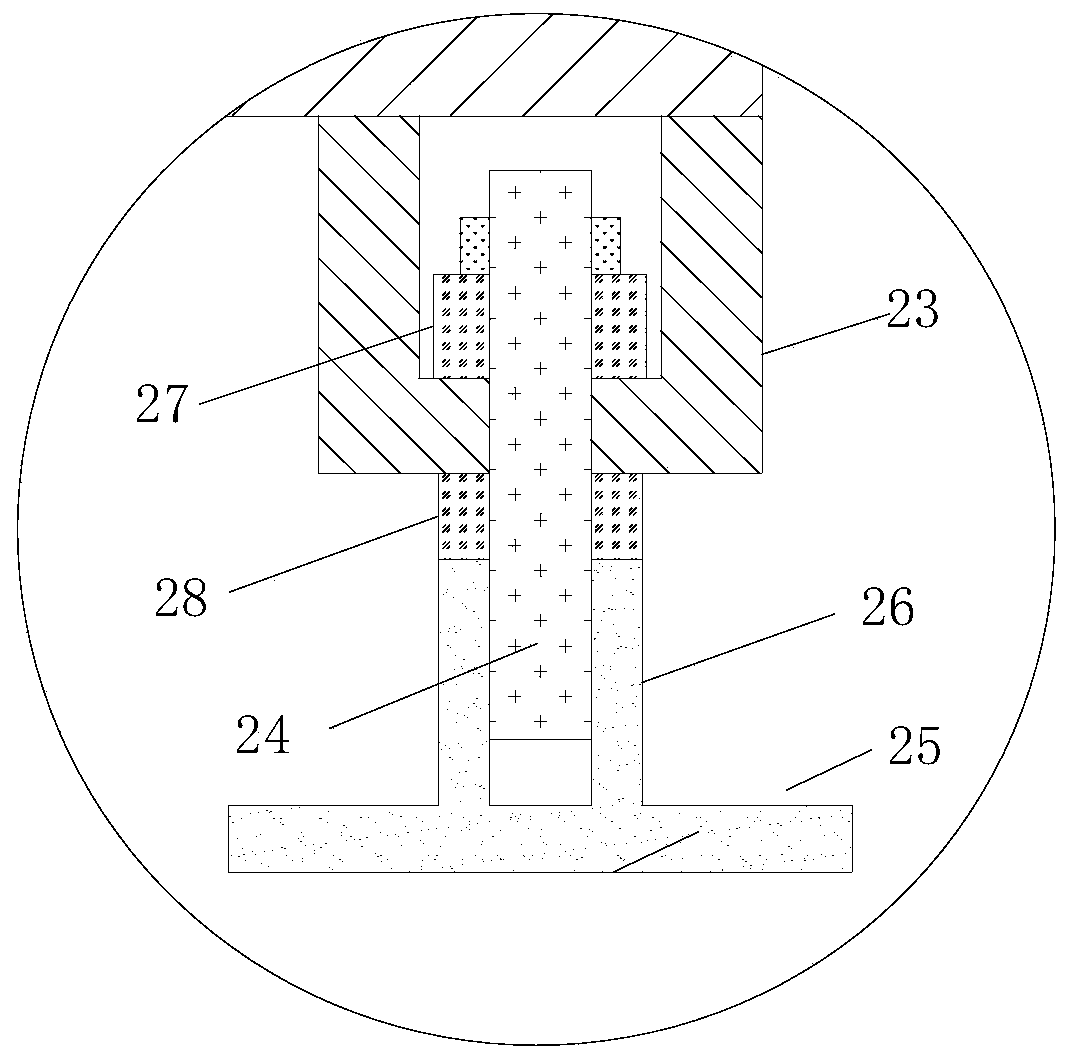

[0027] refer to Figure 1-6 , the present invention provides a technical solution: a high-pressure plunger pump skid-mounted device for oil field water injection, including a plunger pump unit 9 fixedly connected to a skid-mounted chassis 1, a plunger pump standby unit 10 and its matching pipeline, In addition, there is an explosion-proof electrical control cabinet 2; the adapter pipeline includes a liquid inlet pipe and a liquid outlet pipe, and a casing can also be provided outside. The device as a whole constitutes a mobile or even container-type skid-mounted device, which is convenient for disassembly and installation, and can be quickly transferred and reused, reducing the installation cost of the water injection pump room, and the setting of the standby unit avoids the easy failure of a single unit problems that hinder work.

[0028] A main liquid inlet valve 4 is arranged between the liquid inlet 3 of the liquid inlet pipeline and the plunger pump unit 9, and the downs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com