Cable buffer layer conductivity defect detection method

A technology for electrical conductivity and defect detection, applied in the direction of testing dielectric strength, fault location, etc., can solve problems such as the inability to effectively connect the outer semi-conductive shield and the metal sheath, the narrow application range, and the inability to meet the performance testing of power cables. Detect the effect of efficient and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

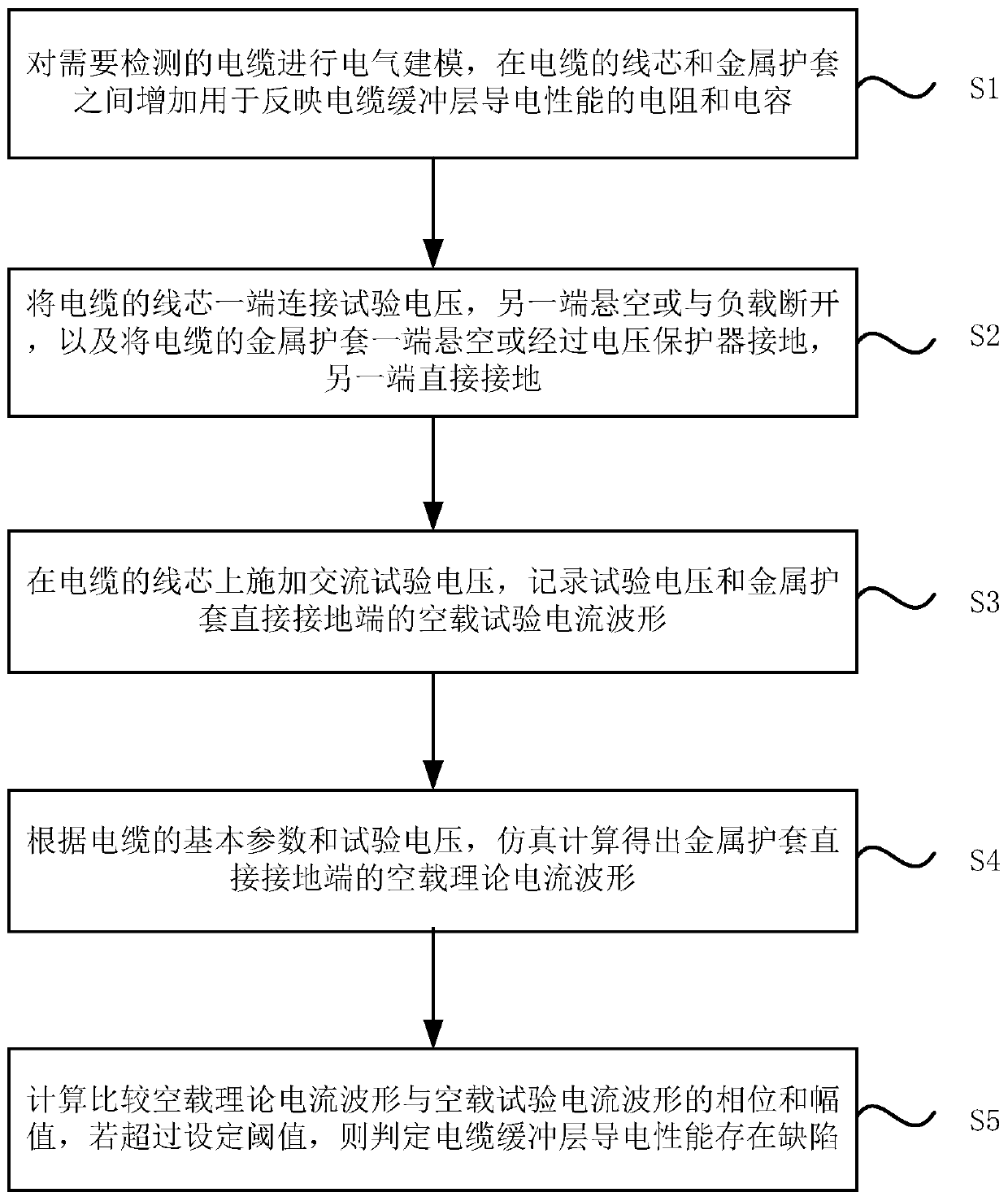

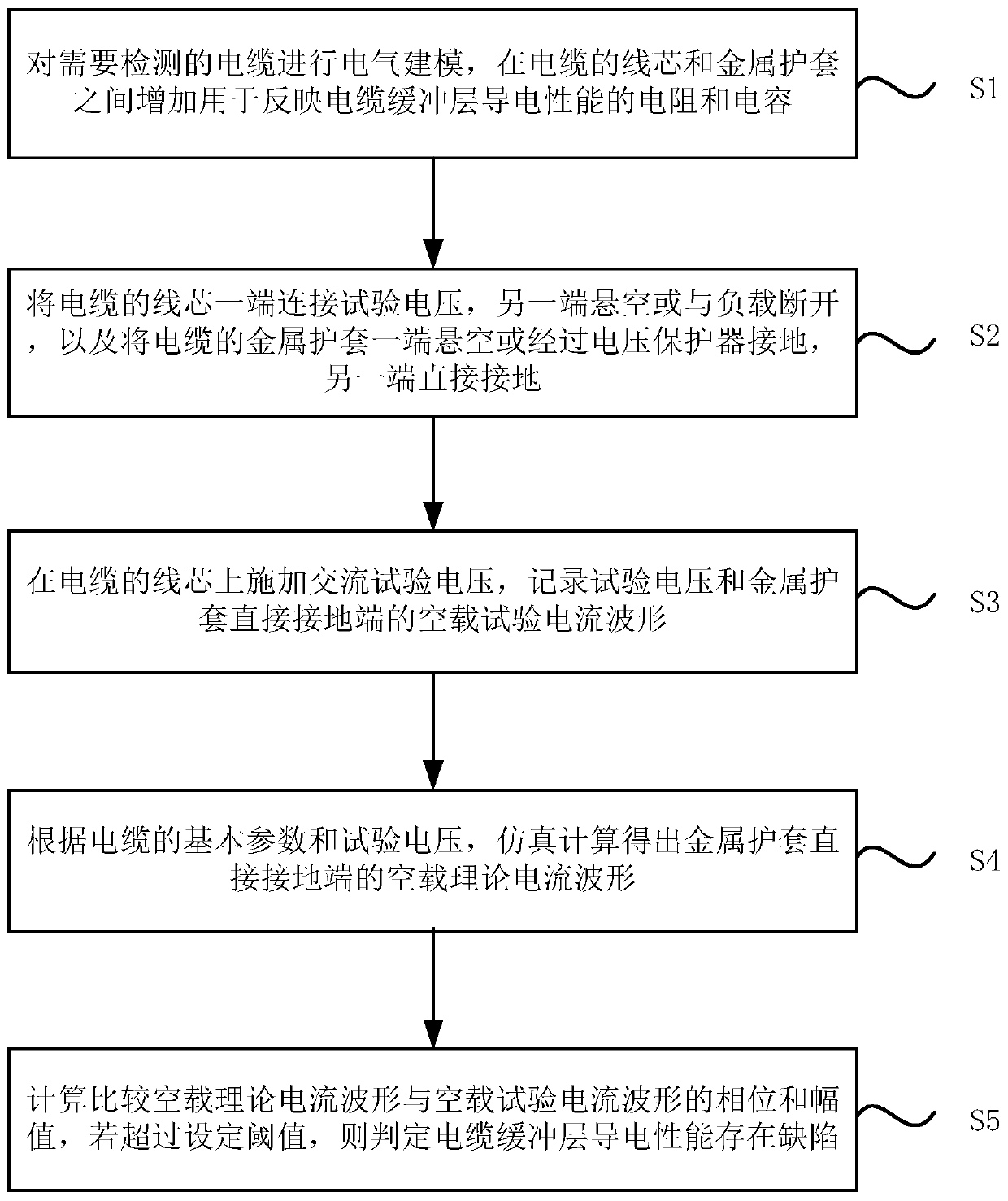

[0023] Please refer to the attached figure 1 , which is a schematic flowchart of a method for detecting a defect in the electrical conductivity of a cable buffer layer provided in Embodiment 1 of the present invention. The method specifically includes the following steps:

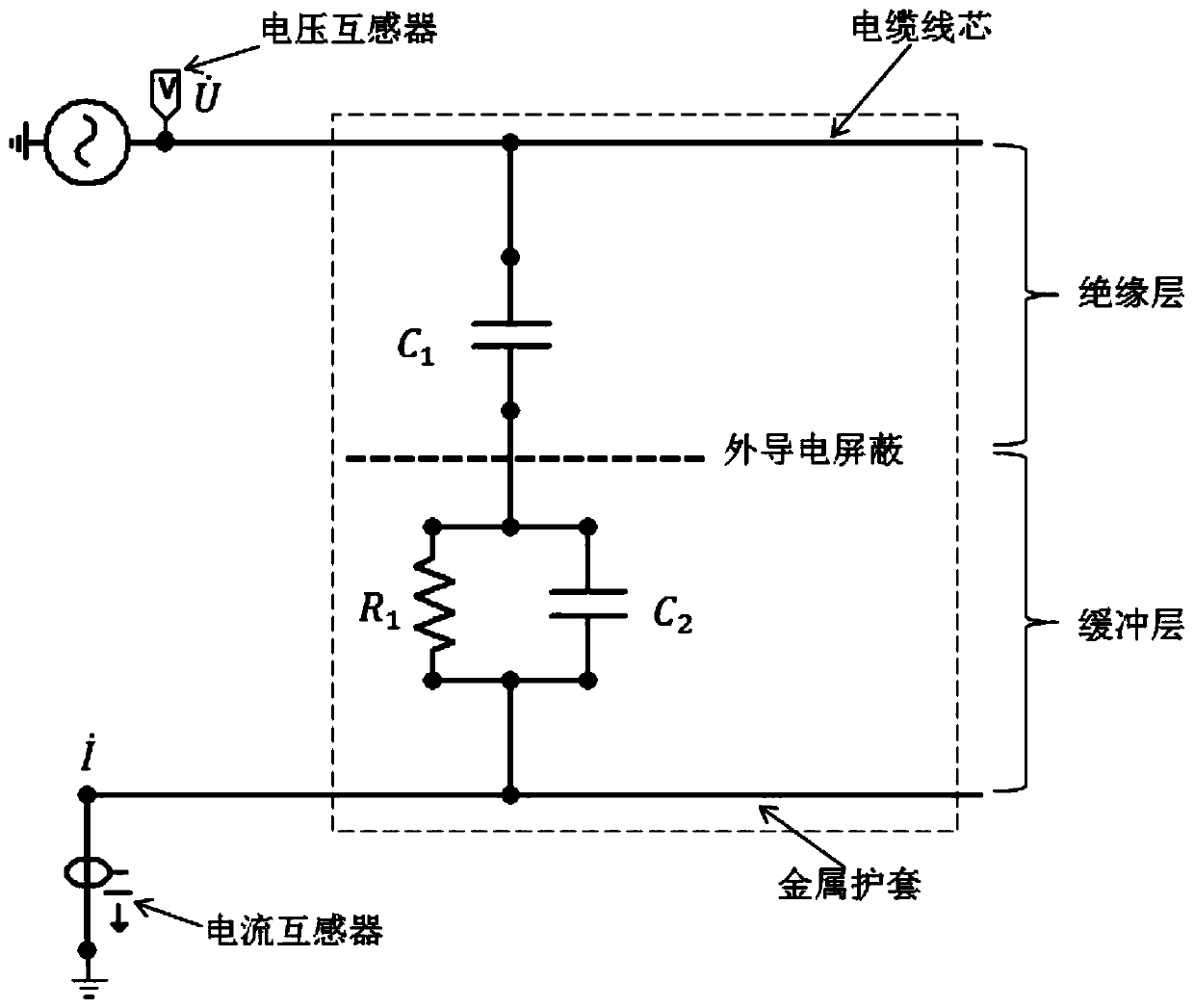

[0024] S1. Perform electrical modeling on the cable to be detected, and add resistance and capacitance between the cable core and the metal sheath to reflect the conductivity of the cable buffer layer.

[0025] It should be noted that the cable to be detected in this embodiment may be a cross-linked polyethylene (XLPE) cable. This embodiment is aimed at a single-core XLPE cable, which is mainly composed of a core, an inner semiconductive shielding layer, an insulating layer, an outer semiconductive shielding layer, a buffer layer, a metal sheath and an outer sheath. The copper wire in the buffer layer is connected to the outer conductive shield and the metal sheath, and there is no potential difference bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com