Method for forming albumen layer by mediating albumin on surface of material, biological material and application thereof

An albumin-mediated technology, applied in the field of biomaterials, can solve the problems that the biocompatibility of titanium and titanium alloys does not meet the clinical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

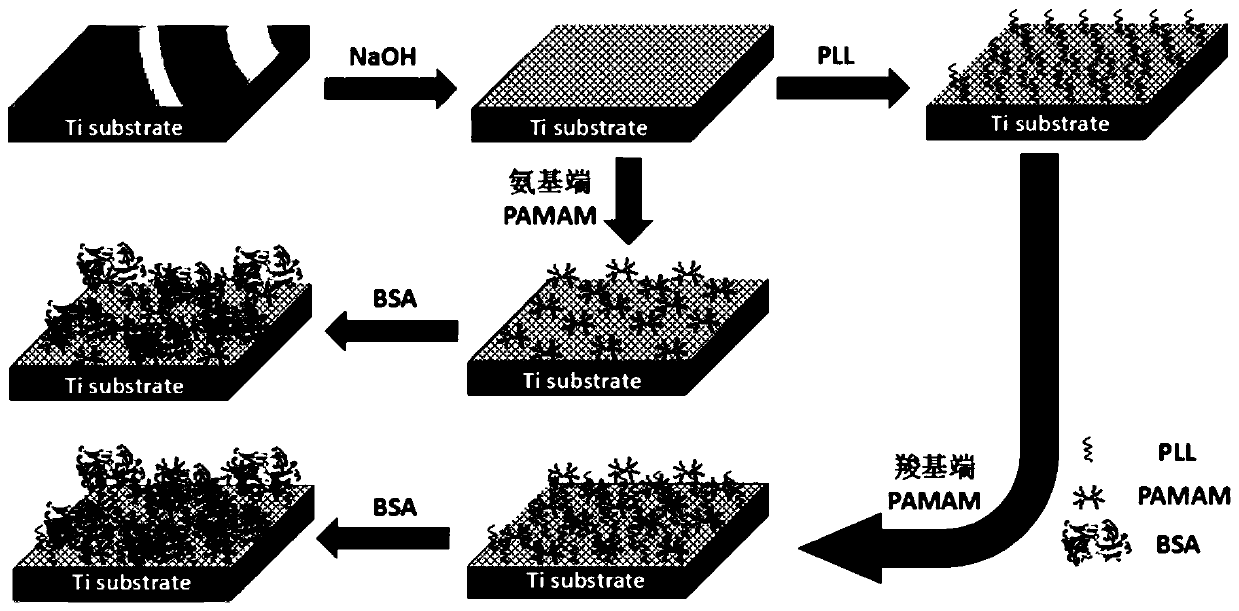

[0050] This embodiment provides a method for mediating albumin to form a protein layer on the surface of a material, which includes the following steps:

[0051] (1) Alkali activation. After cleaning the surface of pure titanium, it is immersed in 2.5mol / L NaOH solution and reacted for 8 hours. Then, after ultrasonic cleaning with RO water, immerse in UP water, let stand at 80°C for 8 hours, ultrasonically clean with UP water, and then dry for use.

[0052] (2) Surface amination. Submerge the alkali-activated sample in a poly-L-lysine solution with a concentration of 2 mg / mL (poly-L-lysine with an average molecular weight of about 150 KDa is dissolved in a phosphate buffer with pH=7), and the reaction 8h, and then washed 3 times with phosphate buffered saline and stored for later use.

[0053] (3) Covalent immobilization of PAMAM. Use PAMAM with a molecular weight of about 1000 (carboxyl at the end) to configure a 0.5 mg / mL dendrimer solution, add carboxyl activator dichlo...

Embodiment 2

[0056] This embodiment provides a method for mediating albumin to form a protein layer on the surface of a material, which includes the following steps:

[0057] (1) Alkali activation. After cleaning the surface of pure titanium, it was immersed in a 3.5mol / L NaOH solution and reacted for 12 hours. Then, after ultrasonic cleaning with RO water, immerse in UP water, let stand at 90°C for 12 hours, ultrasonically clean with UP water, and dry for later use.

[0058] (2) Surface amination. Submerge the alkali-activated sample in a poly-L-lysine solution with a concentration of 3 mg / mL (poly-L-lysine with an average molecular weight of about 300 KDa is dissolved in a phosphate buffer solution of pH=8), and the reaction 12h, and then washed 3 times with phosphate buffered saline, and then stored for future use.

[0059] (3) Covalent immobilization of PAMAM. Use PAMAM with a molecular weight of about 100,000 (carboxyl at the end) to configure a 10 mg / mL dendrimer solution, add ca...

Embodiment 3

[0062] This embodiment provides a method for mediating albumin to form a protein layer on the surface of a material, which includes the following steps:

[0063] (1) Alkali activation. After cleaning the surface of pure titanium, it is immersed in 3mol / L NaOH solution and reacted for 10 hours. Then, after ultrasonic cleaning with RO water, immerse in UP water, let stand at 85° C. for 10 hours, ultrasonically clean with UP water, and then dry for use.

[0064] (2) Surface amination. Submerge the alkali-activated sample in a poly-L-lysine solution with a concentration of 2.5 mg / mL (poly-L-lysine with an average molecular weight of about 200 KDa is dissolved in a phosphate buffer with pH=7.4), React for 10 h, then wash with phosphate buffered saline for 3 times and store for future use.

[0065] (3) Covalent immobilization of PAMAM. Use PAMAM with a molecular weight of about 9000 (carboxyl at the end) to configure a 1 mg / mL dendrimer solution, add carboxyl activator N-hydroxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com