Piston sealing ring of hydraulic motor

A technology of hydraulic motor and sealing ring, applied in the field of hydraulic motor, can solve the problems of poor sealing effect of the sealing ring, etc., and achieve the effects of good sealing, convenient realization and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

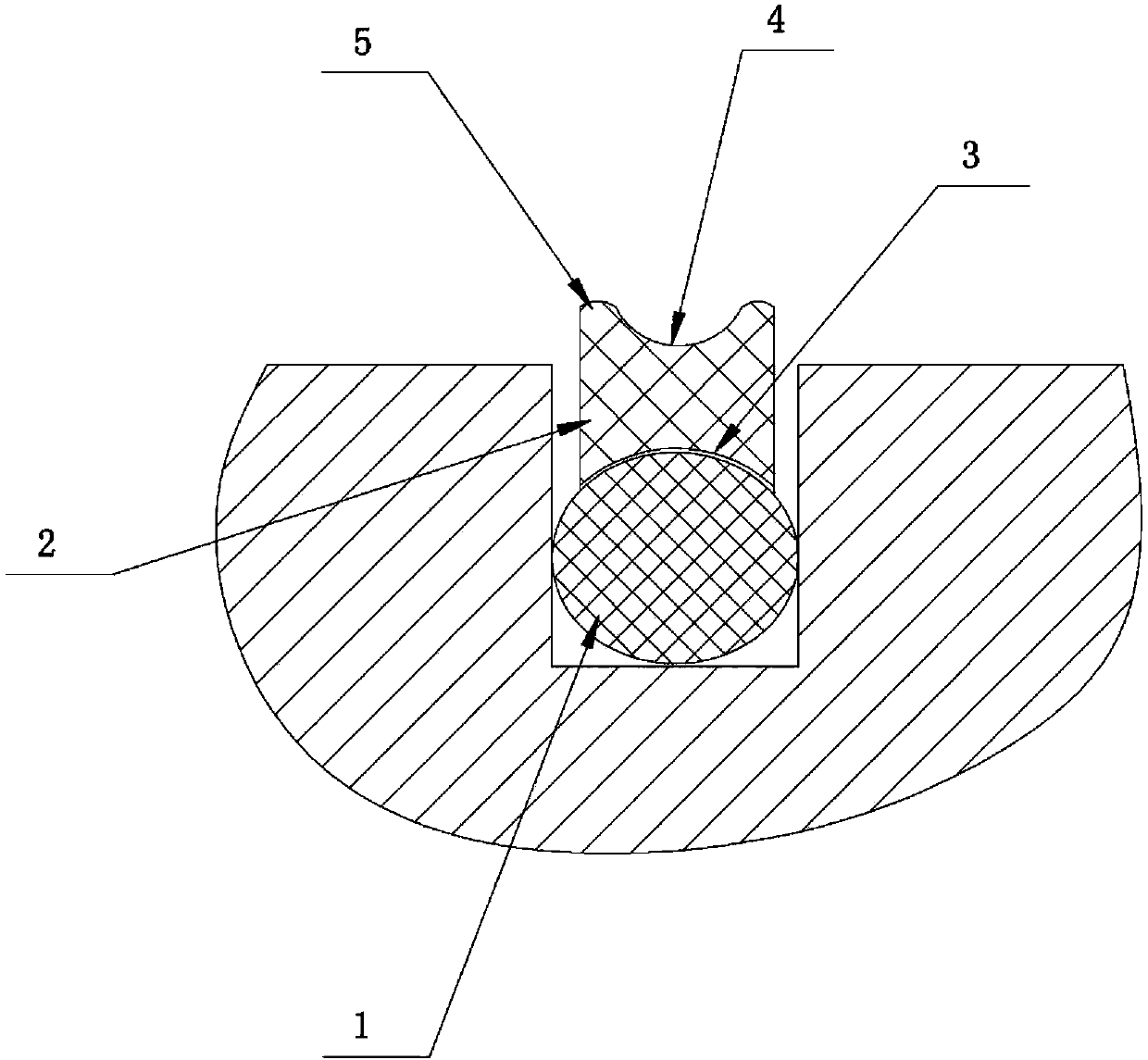

[0011] refer to figure 1 , the present invention provides a hydraulic motor piston sealing ring, including: an O-ring 1 and a sealing ring 2, the inner side of the sealing ring 2 is provided with an arc-shaped groove 3 matching the O-ring 1, the sealing The outer side of the ring 2 is provided with an arc-shaped oil storage groove 4, and the sealing ring 2 forms arc-shaped protrusions 5 on both sides of the arc-shaped oil storage groove 4, and the arc-shaped protrusions 5 contact the inner wall of the outer cylinder.

[0012] The sealing ring of the hydraulic motor piston in this embodiment is composed of an O-ring and a sealing ring. Lubricating oil can be placed in the arc-shaped oil storage tank, which effectively reduces the working temperature and has a good noise reduction effect. The arc-shaped protrusions are in contact with the inner wall of the external cylinder. , good sealing, the overall structure is stable, easy to realize.

[0013] The above is only a preferred...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com