Non-contact laser precise cylindrical gear profile radial eccentricity detection method

A cylindrical gear, non-contact technology, applied in the field of non-contact laser precision detection of radial eccentricity of cylindrical gear tooth profile, can solve the problems of affecting measurement accuracy, high cost, cumbersome work, etc., to achieve accurate measurement results, reduce economic costs, and detect Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

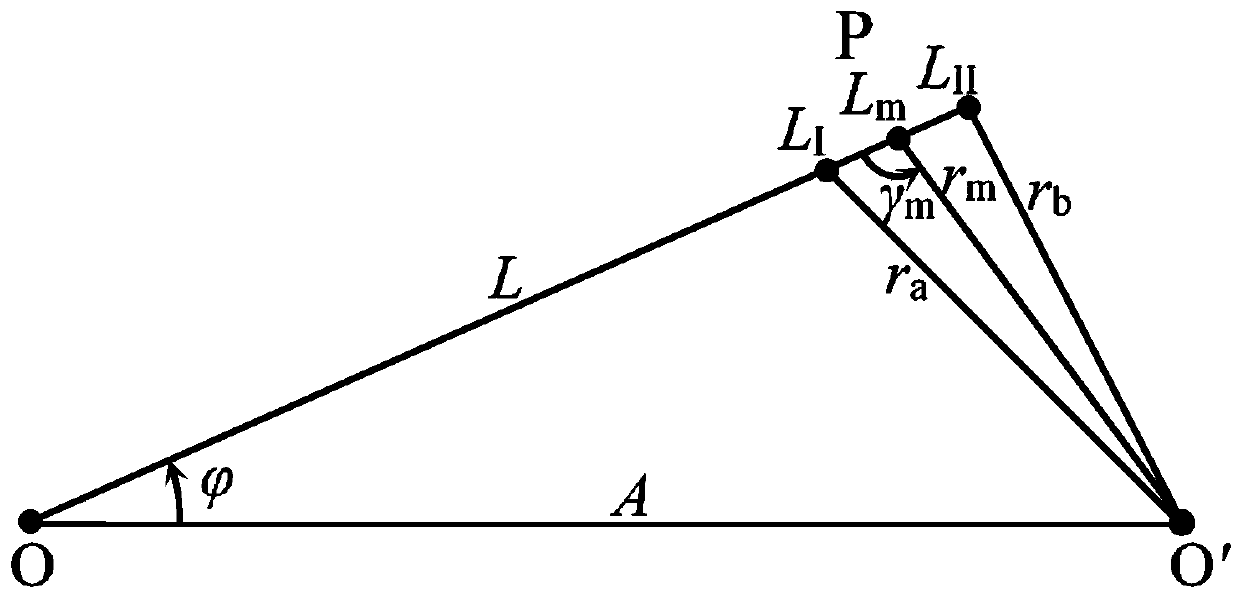

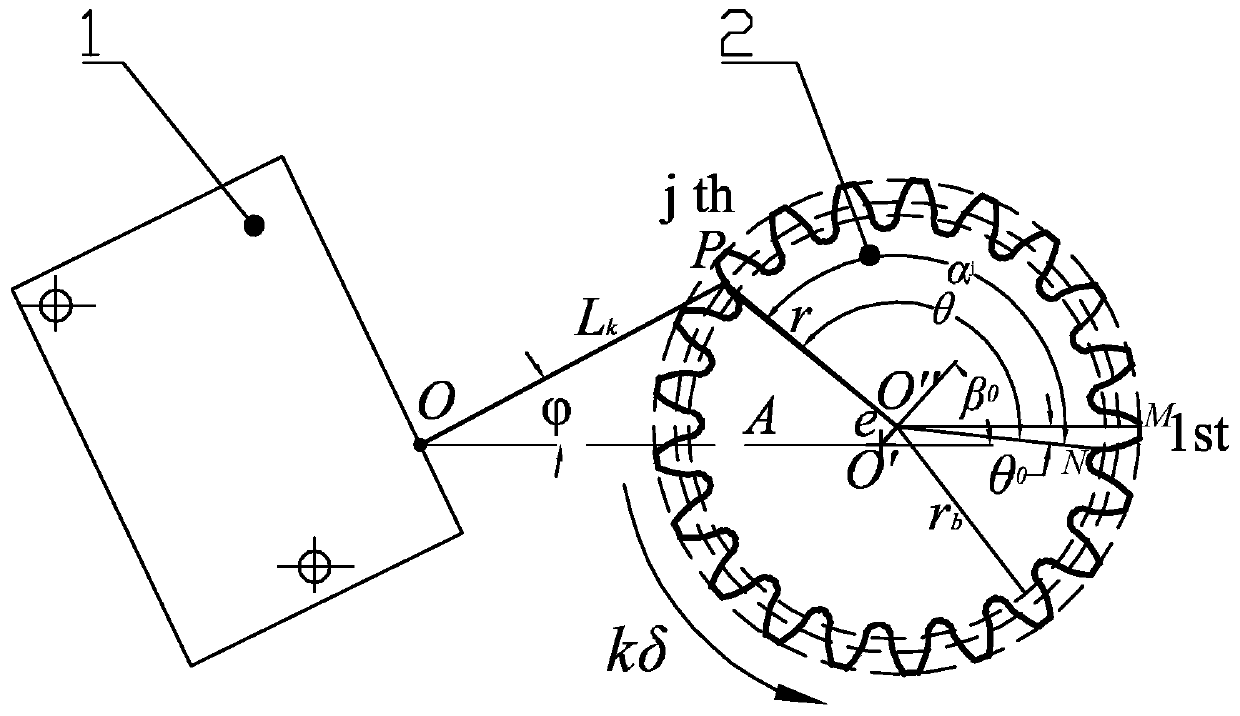

[0016] In order to adapt to the specific range L∈[L of the laser displacement sensor a , L b ], the measurement accuracy should satisfy the limit of the angle between the laser line and the normal line of the tooth profile |ξ|max , to avoid the excessively large measurement area caused by the slender laser beam spot covering the tooth profile, and to reduce the measurement error caused by the incident angle of the laser, the relative placement position A and A of the laser displacement sensor and the measured gear Strict optimization is definitely required.

[0017] Such as figure 1 , figure 2 As shown, the range of A is r a ~ L b + r a , The range is 0~arcsin(r a / A), r a is the radius of the addendum circle, r b is the radius of the base circle. Using the numerical calculation technology of the tooth profile curve, the angle between the laser line correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com