Industrial CPS system and realization method for personalized customization

An implementation method and industrial technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of realization method dependence, the industrial production line CPS system framework does not have a unified structure, etc., to save development time, and to benefit The effect of promotion and convenient direct use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described in detail below in conjunction with the examples.

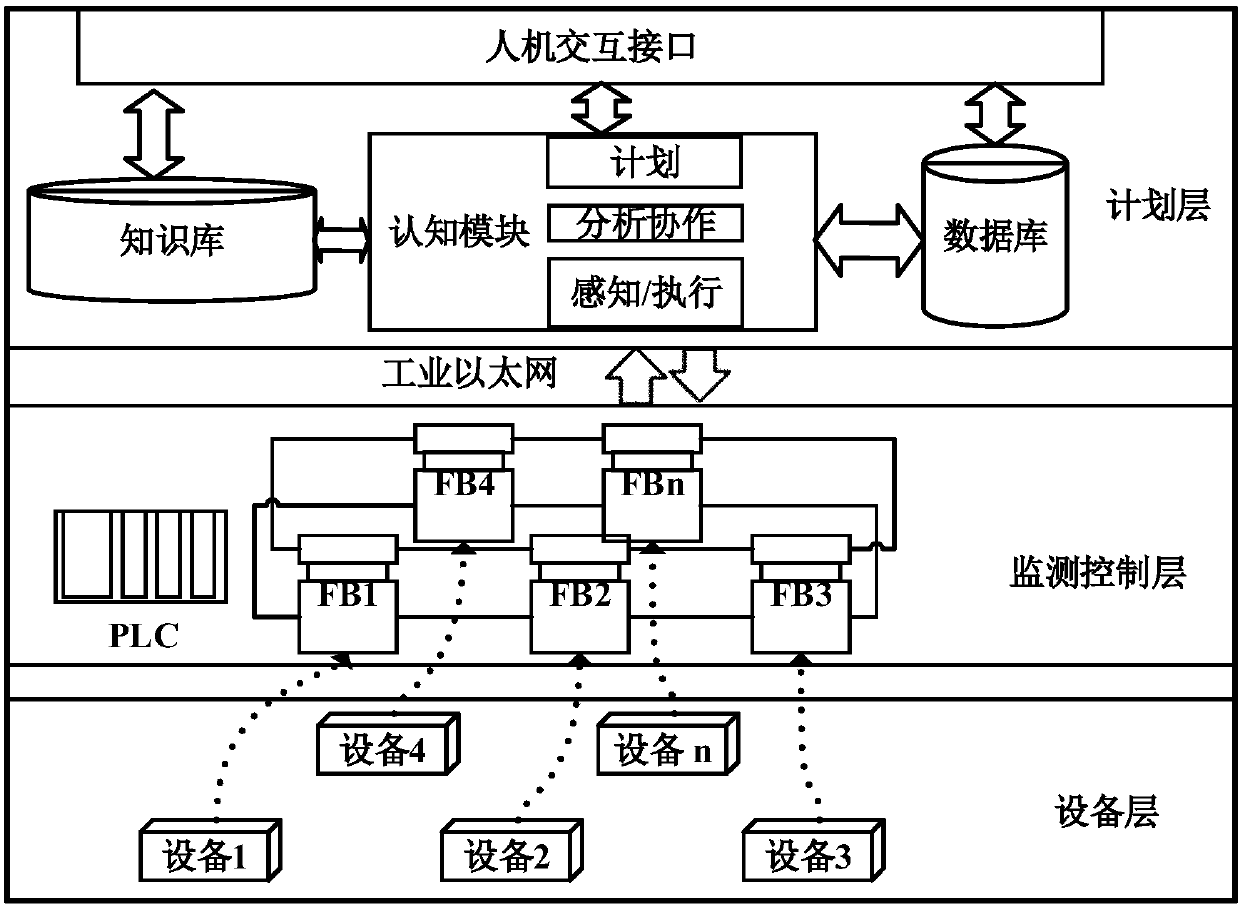

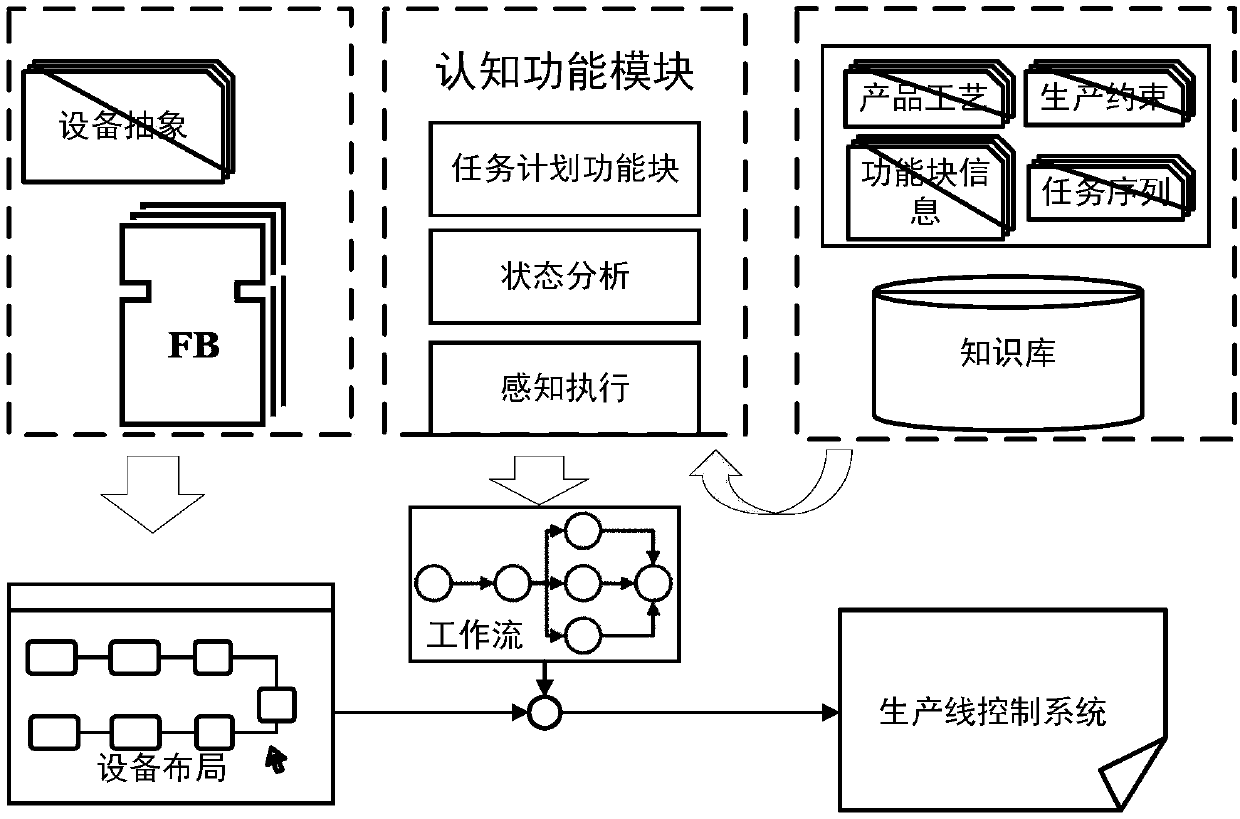

[0057] According to one aspect of the present invention, the present invention provides an industrial production line CPS system framework oriented to personalization, including: equipment layer, monitoring control layer and planning layer.

[0058] The device layer is used to represent standard automated physical devices. These devices have independent functions and can complete specific tasks (for example, the manipulator can grasp and assemble, the stopper can be raised and lowered, etc.), and have callable interfaces to realize information transmission between devices and between the device layer and the monitoring control layer Including monitoring of trigger signals, transmission of control signals and feedback of completion signals.

[0059] The monitoring and control layer is used to monitor, process and display events that occur during system operation, and effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com