Neural network inverse control method for SCR denitration system of coal-fired unit

A neural network inverse technology for coal-fired units, applied in the field of neural network inverse control for SCR denitrification systems of coal-fired units, can solve problems such as lag, difficult control of SCR denitrification systems, and drastic changes in NOx concentration measurements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0028] There are three main aspects to realize the inverse control of the SCR denitrification system. One is the establishment of the mechanism model of the SCR denitrification system.

[0029] (1) Mechanism model of SCR denitrification system

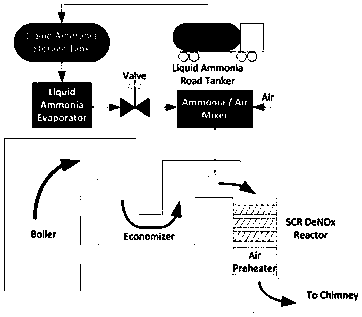

[0030] This paper takes a 600MW unit as an example, the process flow chart of the SCR denitrification system is as follows figure 1 shown. The SCR denitration system is composed of liquid ammonia storage system, liquid ammonia evaporation system and SCR denitration reaction system. The SCR denitration reaction system generally adopts high temperature and high fly ash layout, that is, the SCR denitration reactor is installed between the economizer and the air preheater. The flue gas generated by the combustion of the boiler enters the denitrification system after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com