Cable

A cable and aramid fiber technology, applied in the field of cables, can solve the problems of complex elevator cable structure, high production and manufacturing costs, and large elevator cable volume, and achieve the effects of compact structure, low use cost and material saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

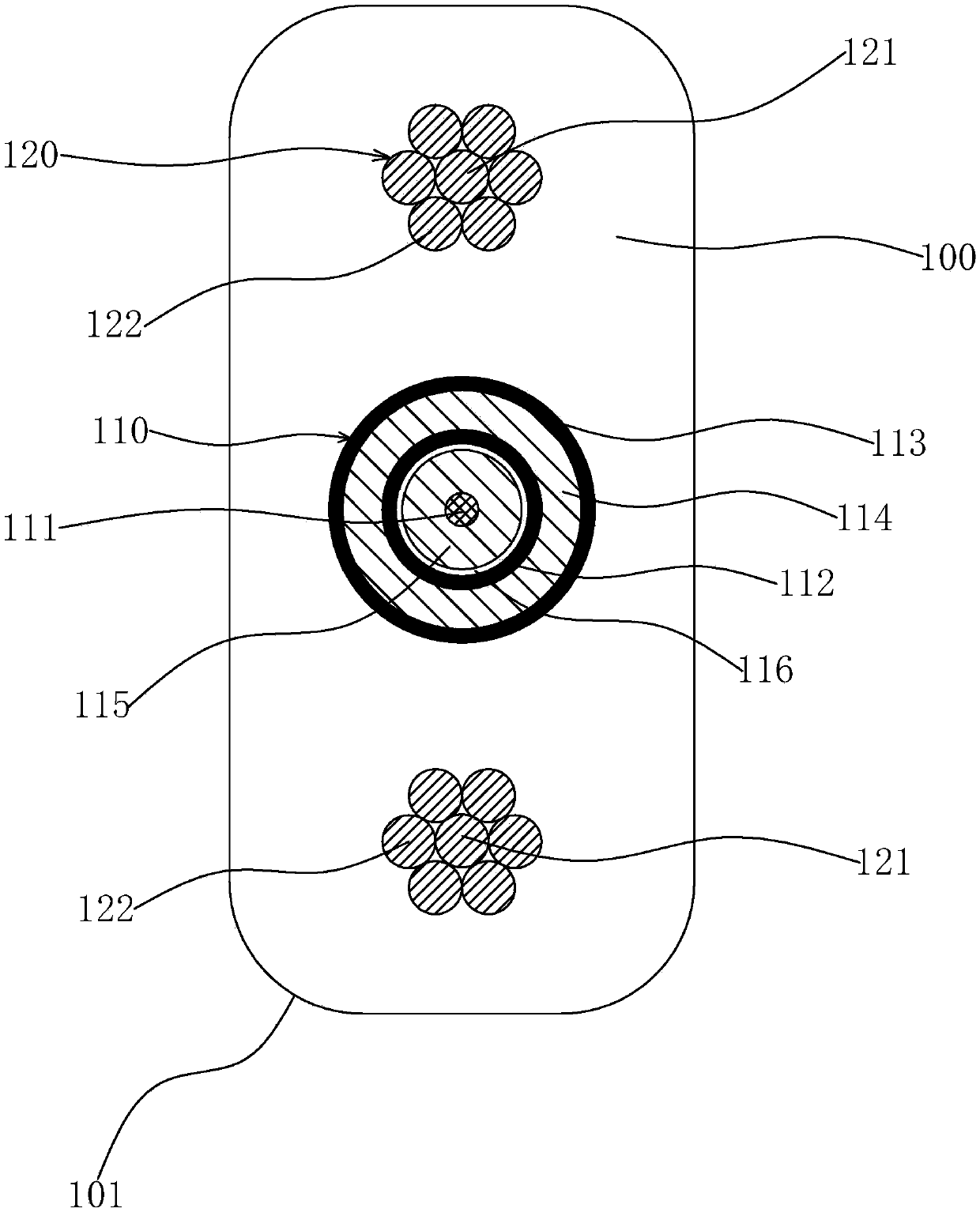

[0014] like figure 1 As shown, a cable of the present invention includes a flat outer sheath 100 and an optical fiber component 110 and a twisted wire 120 wrapped in the outer sheath 100 .

[0015] The optical fiber assembly 110 is located at the inner center of the entire outer sheath 100. There are two twisted wires 120 located on both sides of the optical fiber assembly 110 respectively. The two twisted wires 120 are arranged symmetrically around the optical fiber assembly 110. The optical fiber assembly 110 It includes an optical fiber main line 111 and a first aramid fiber layer 112 and a second aramid fiber layer 113 arranged outside the optical fiber main line 111 in sequence, and an inner sheath 114 is arranged bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com