Encapsulation glue and packaging structure

An encapsulant and adhesive technology, which is applied in nanotechnology for materials and surface science, semiconductor/solid-state device components, semiconductor devices, etc. and problems such as unsatisfactory service life, unsatisfactory thermal conductivity and heat dissipation performance, etc., to achieve the effect of improving continuous heat dissipation capacity, ensuring stability and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Based on the modified hollow microspheres described above in the embodiments of the invention, the present invention also provides a preparation method of the modified hollow microspheres. The preparation method of the modified hollow microspheres comprises the following steps:

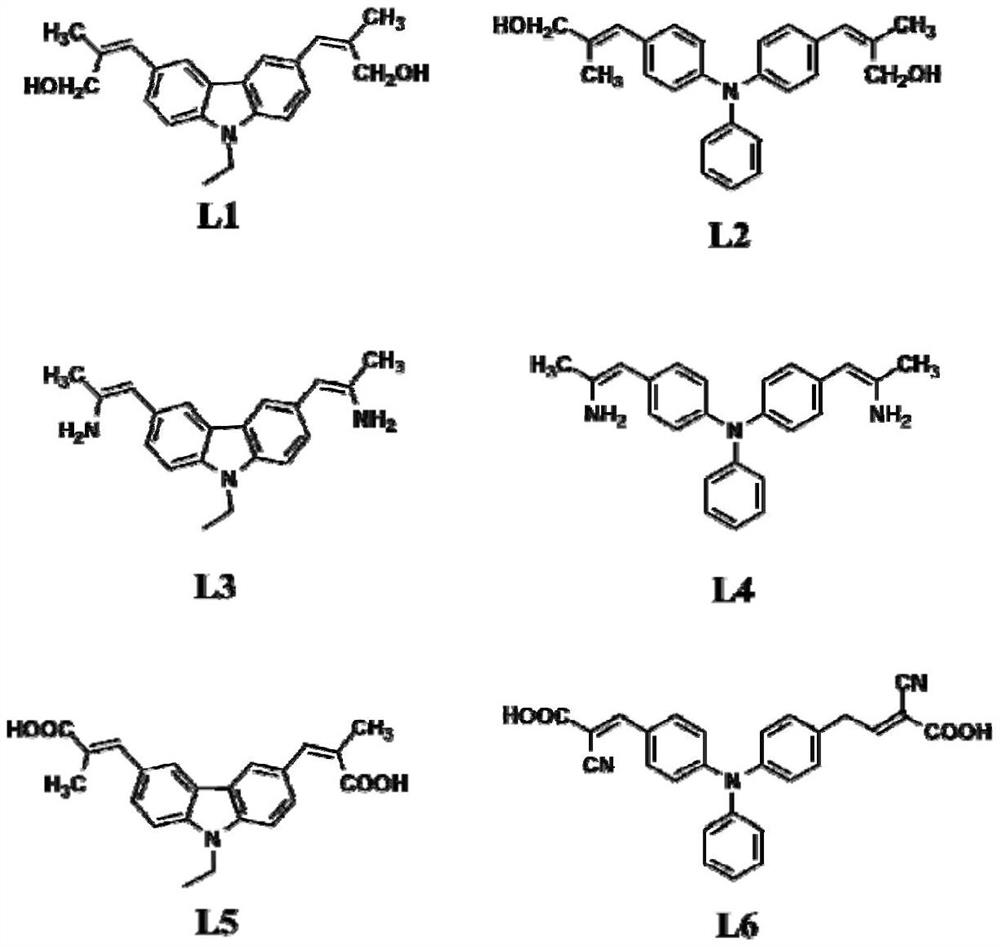

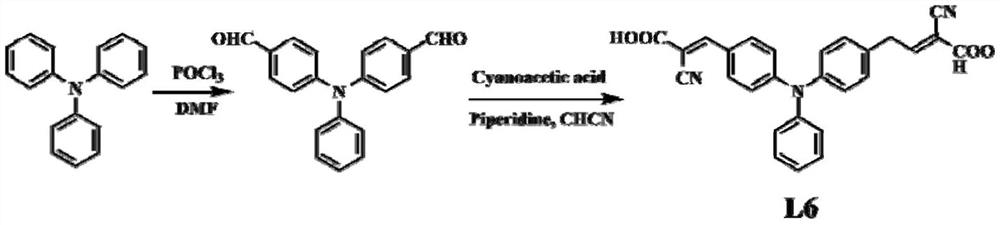

[0031] Carry out surface grafting treatment to the hollow microsphere matrix, so that the organic compound is grafted onto the surface of the hollow microsphere to form a hollow microsphere with an organic compound bound to the surface. The general structural formula of the organic compound is A1-D-A2, and the A1 and A2 are electron-withdrawing groups, and D is an organic group with symmetrical molecular structure.

[0032] In one embodiment, the hollow microsphere matrix is subjected to surface grafting treatment, and the step of grafting the organic compound onto the hollow microsphere surface includes:

[0033] Preparation of organic solutions containing isocyanate groups;

[0034] Add h...

Embodiment 11

[0061] This embodiment provides a modified hollow microsphere and its preparation method. The modified hollow microspheres include a polyurethane hollow microsphere matrix and the aforementioned L1 compound combined on the polyurethane hollow microsphere matrix.

[0062] The modified hollow microspheres described in Example 11 were prepared according to the following method:

[0063] (1) Preparation of polyurethane hollow microsphere matrix: Prepare hot hollow microspheres by Pickering suspension polymerization method, weigh 0.5g nanometer Mg(OH) 2 , 0.25g NaCl, 0.01g NaNO 2Dissolve in 50mL deionized water, stir for 15 minutes and mix evenly as the aqueous phase of suspension polymerization; weigh 14g acrylonitrile, 4g methyl methacrylate, 2g butyl acrylate, 0.08g trimethylolpropane trimethacrylate, 0.4g of azobisisobutyronitrile and 7g of isooctane were stirred at room temperature for 30 minutes and mixed uniformly as the oil phase; after mixing the water phase and the oil ...

Embodiment 12

[0066] This embodiment provides a modified hollow microsphere and its preparation method. The modified hollow microspheres include a polyurethane hollow microsphere matrix and the above-mentioned L3 compound combined on the polyurethane hollow microsphere matrix.

[0067] The modified hollow microspheres described in Example 12 were prepared according to the following method:

[0068] (1) Preparation of polyurethane hollow microsphere matrix: prepare with reference to the step (1) of Example 11;

[0069] (2) Modification of the polyurethane hollow microsphere matrix: preparation according to step (2) of Example 11, except that L3 is used to modify the polyurethane hollow microsphere matrix.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com