Silicon-based molybdenum disulfide heterojunction photoelectric sensor and preparation method

A silicon-based molybdenum disulfide, photoelectric sensor technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of low light absorption rate, high light response current, complex preparation process, etc., to improve light absorption efficiency and fast response. time, reducing the effect of compounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

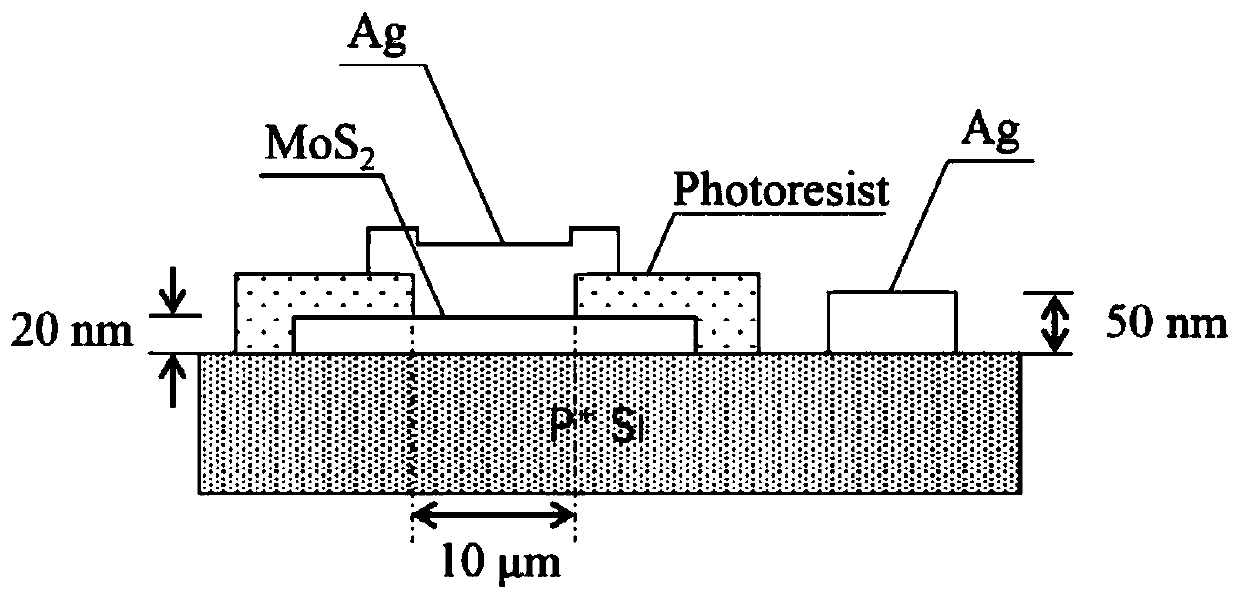

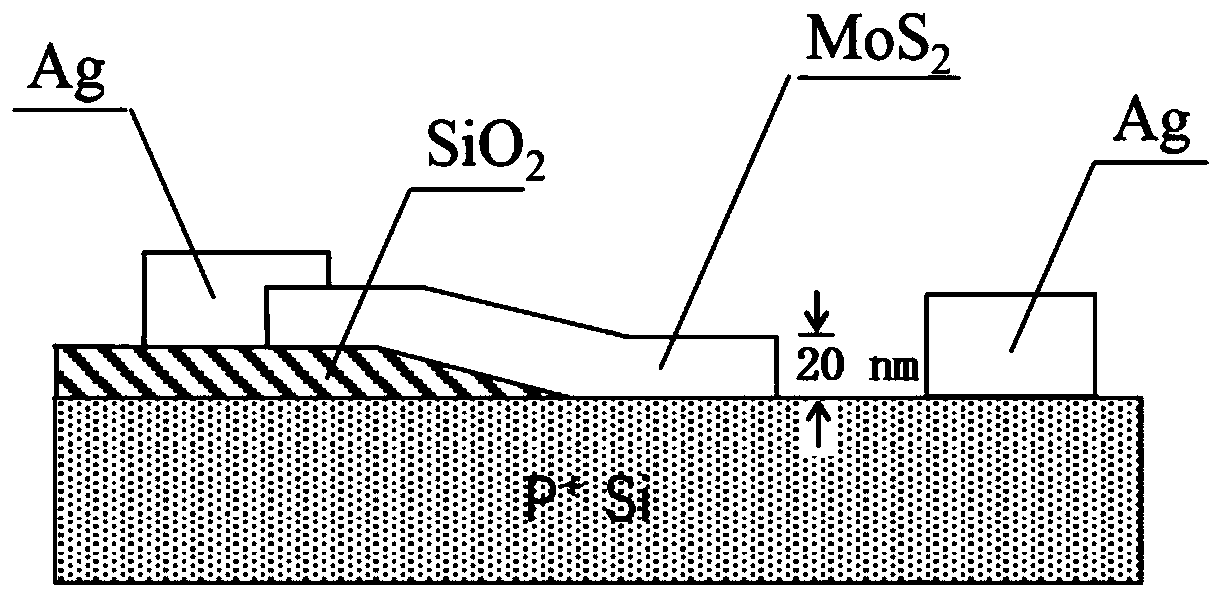

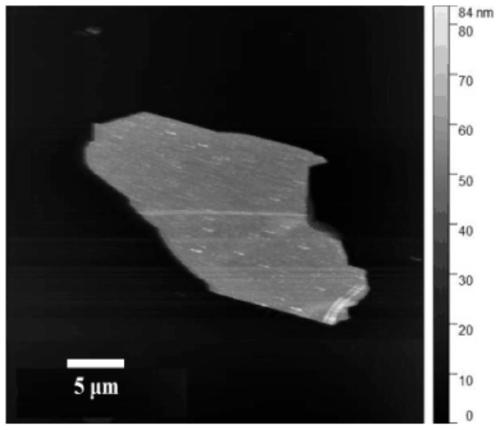

[0024] This example provides MoS based on multilayer thickness molybdenum disulfide 2 / Si heterojunction photosensor, its structure is as figure 1 As shown, including: P-type heavily doped silicon substrate, multi-layer molybdenum disulfide (MoS 2 ), photoresist (Photoresist), top electrode and bottom electrode; wherein, the multilayer molybdenum disulfide is arranged on the upper surface of the P-type heavily doped silicon substrate; the photoresist is coated on the multilayer molybdenum disulfide The upper surface is covered with multiple layers of molybdenum disulfide; a window is opened on the photoresist, and the top electrode is arranged on the multi-layer molybdenum disulfide through the window, and conducts with the multi-layer molybdenum disulfide; the bottom electrode It is arranged on the upper or lower surface of the P-type heavily doped silicon substrate.

[0025] In this embodiment, the number of layers of multilayer molybdenum disulfide is more than 10, the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com