A kind of quantum dot modified zno nanorod array electrode and preparation method thereof

A nanorod array, quantum dot technology, applied in nanotechnology, nanotechnology, cable/conductor manufacturing, etc., can solve the problems of low photocatalytic efficiency and low utilization of sunlight, achieve high activity, improve photocatalytic efficiency, The effect of increasing photosensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

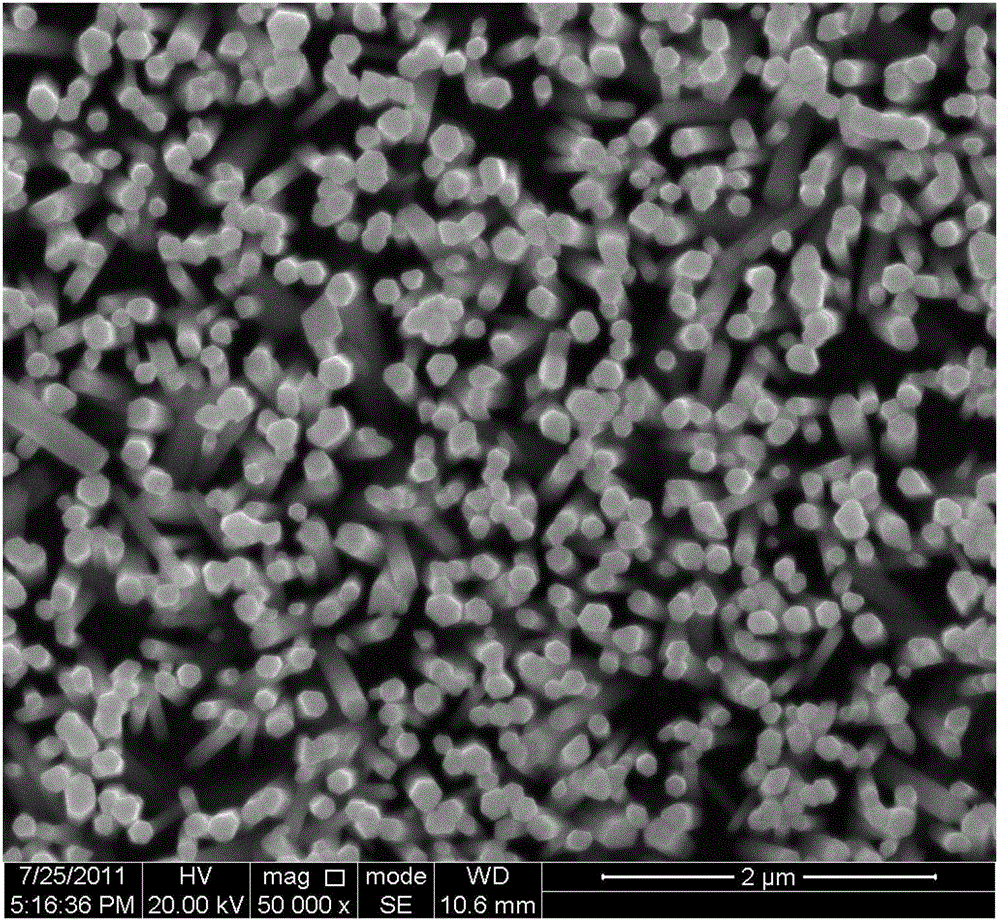

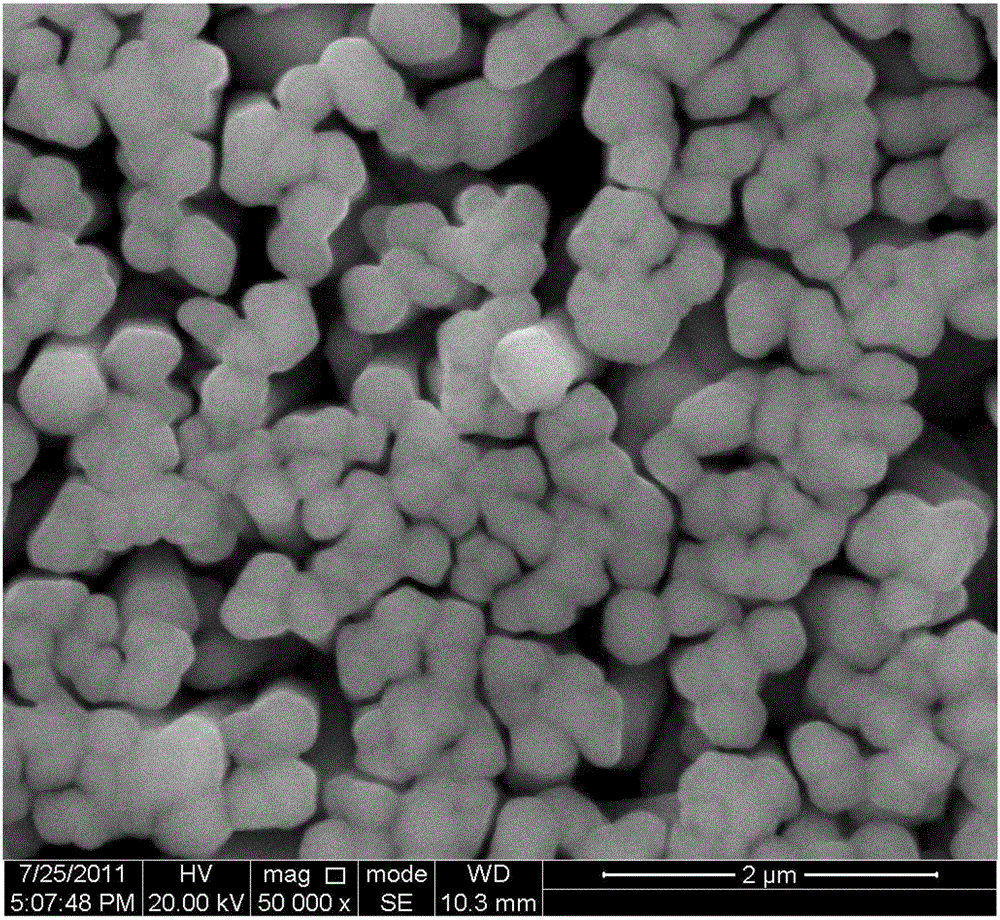

[0044] Embodiment 1: A quantum dot modified ZnO nanorod array electrode of this embodiment includes a substrate, a ZnO nanorod array and a quantum dot coating layer; wherein, the substrate is a conductive substrate, and the ZnO nanorod array is It is made of zinc nitrate hexahydrate with a concentration of 0.08-0.12M and hexamethylenetetramine with a concentration of 0.08-0.12M, and the volume ratio of zinc nitrate hexahydrate and hexamethylenetetramine is 1: 1. The quantum dot coating layer is alternately coated with cationic polyelectrolyte-o-phenanthroline cobalt layers and quantum dot nanoparticle layers, and the cationic polyelectrolyte-o-phenanthroline cobalt layer is coated on ZnO On the nanorod array, the quantum dot nanoparticle layer is coated on the cationic polyelectrolyte-o-phenanthroline cobalt layer, wherein the quantum dot nanoparticle layer is a CdTe nanoparticle layer, a CdS nanoparticle layer or a CdSe nanoparticle layer .

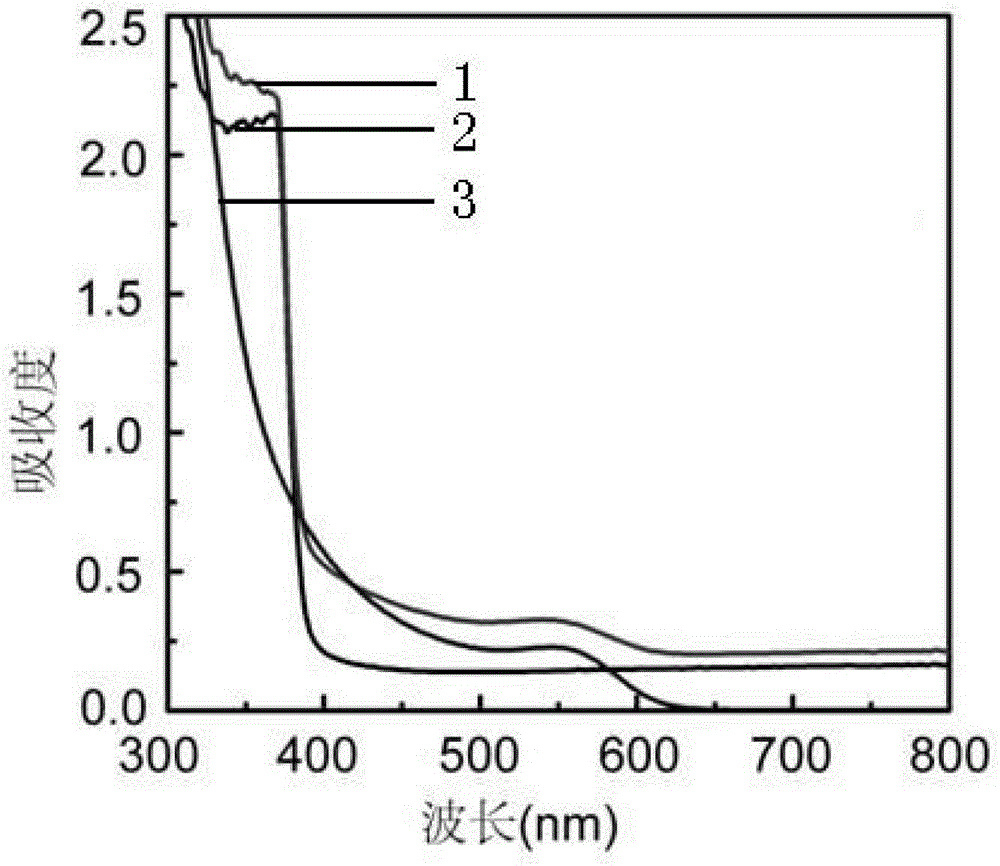

[0045] The absorption of the qua...

specific Embodiment approach 2

[0046] Embodiment 2: This embodiment is different from Embodiment 1 in that: the conductive substrate is ITO or FTO. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0047] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the preparation method of the cationic polyelectrolyte-o-phenanthroline cobalt layer is as follows: soak the ZnO nanorod array in a pH of 6.2-8.5 After 5-20 minutes in the cationic polyelectrolyte-o-phenanthroline cobalt solution, take it out, rinse it with deionized water, and dry it to complete;

[0048] Wherein, the cationic polyelectrolyte-o-phenanthroline cobalt solution is composed of o-phenanthroline cobalt with a concentration of 0.5-2 mg / mL and a cationic polyelectrolyte with a concentration of 0.2-1 mg / mL; wherein, the Cationic polyelectrolyte—the cationic polyelectrolyte in the o-phenanthroline cobalt layer is polyethyleneimine, polyallylamine hydrochloride or polydimethyldiallylammonium chloride. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com