Electroconductive film, and method for manufacturing electroconductive film

A technology of conductive film and manufacturing method, which is applied in the direction of chemical instruments and methods, cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, etc., which can solve the problems of conductive anisotropy, transparency, and difficulty in reducing The use of conductive materials and other issues, to achieve the effect of excellent stability of resistance value and excellent cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

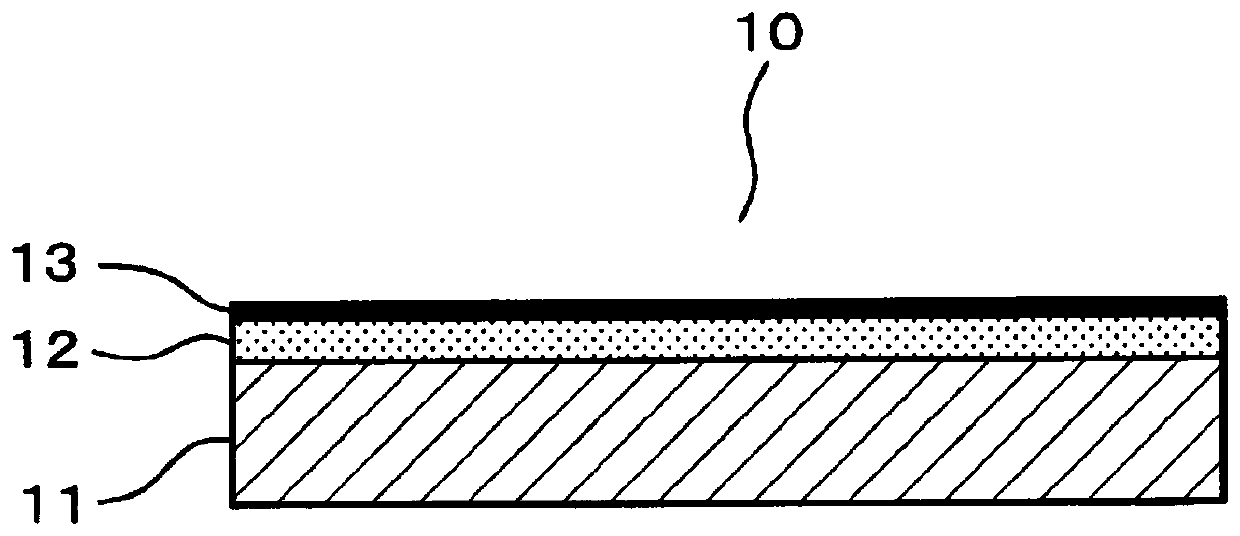

Image

Examples

Embodiment 1

[0086]

[0087] As the binder resin, use -SO 3 Na-based polyester resin aqueous dispersion. This aqueous polyester dispersion was prepared using PES resin A-647GEX manufactured by Takamatsu Oil & Fat Co., Ltd. so that the solid content concentration would be 5% by mass. Hereinafter, such an aqueous polyester dispersion is referred to as a PES resin aqueous solution.

[0088] Methanol (MeOH) and 2-propanol (IPA) were prepared in order to prepare a mixed dispersion medium of water+alcohol by mixing with water as the dispersion medium of the above-mentioned silver nanowire dispersion liquid.

[0089] The above-mentioned silver nanowire dispersion using water as a dispersion medium and the above-mentioned 5% by mass aqueous solution of PES resin were placed in a container with a lid, and various solvents were added, and the lid was put on and mixed with a mixing rotor. In this case, the mixed composition of the solvent was water:MeOH:IPA mass ratio=72:18:10. In addition, the ...

Embodiment 2

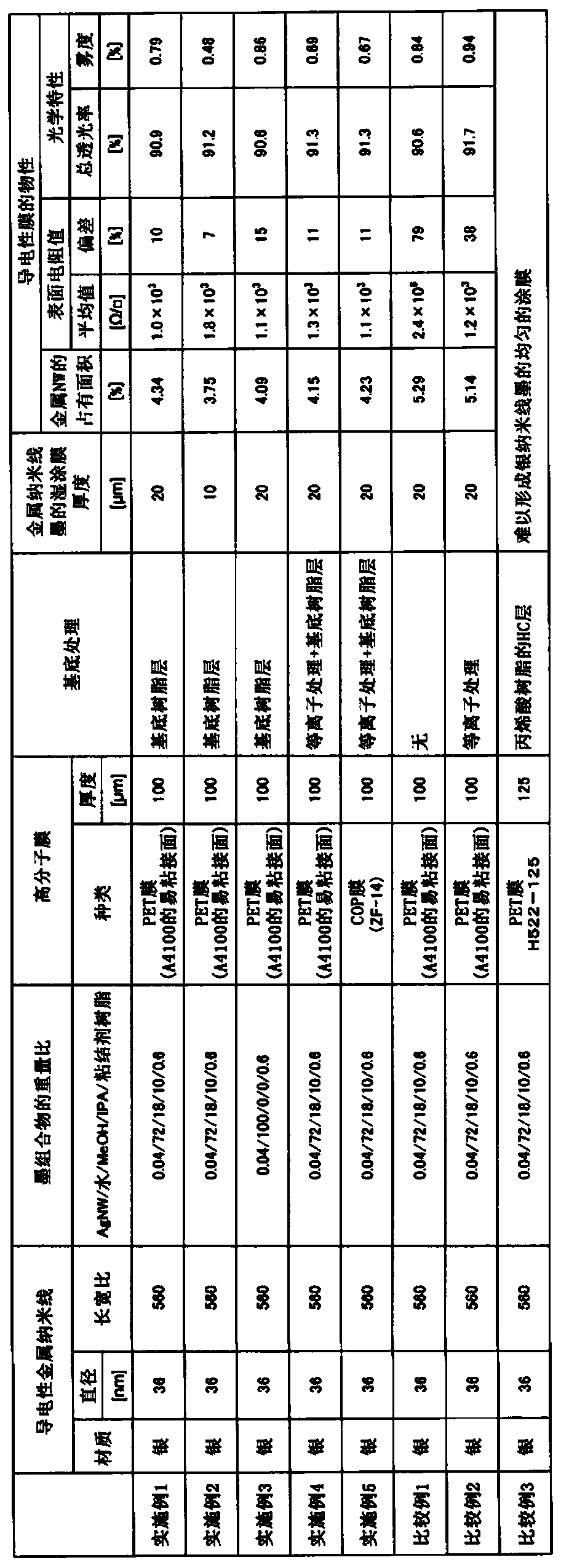

[0109] The difference from Example 1 is that the silver nanowires are coated so that the wet film thickness becomes about 10 μm. Except for this point, it carried out similarly to Example 1. The results are shown in Table 1. It was confirmed that the occupied area of silver nanowires (AgNW) of the obtained conductive film was 3.75%, and the surface resistance value was 1.8×10 3 Ω / □, the variation of the surface resistance value is less than 7%, and the conductive film has uniform conductivity. In addition, it was confirmed that the total light transmittance was higher than 91.2%, the haze was less than 0.48%, and the transparency was extremely excellent.

Embodiment 3

[0111] The difference from Example 1 is that the silver nanowire ink using water solvent. Except for this point, it carried out similarly to Example 1. The results are shown in Table 1. Compared with Example 1 in which a mixed solvent of water and alcohol was used, the variation in the surface resistance value was slightly more than 15%, but it was a level that would not hinder the use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

| Average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com