Film mulching cultivation method for potatoes

A cultivation method and film-covering technology, applied in the field of potato film-covering cultivation, can solve problems such as unfavorable large-scale planting and mechanized harvesting of potatoes, unrecyclable use of ordinary film, and impact on the agricultural ecological environment, so as to increase yield and commercial potato rate, The effect of increasing the rate of commercial potatoes and saving steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Land selection and land preparation: Select fields with sufficient water sources, convenient irrigation, and rice as the previous crop, which can not only make full use of mineral elements and nutrients in the soil, but also can significantly reduce the occurrence of potato diseases and insect pests, and rice harvest Afterwards, fertilization: use chicken manure organic fertilizer 600kg, compound fertilizer 120kg; This compound fertilizer selects Sumisho compound fertilizer (16:8:18), wherein contains N ≥ 16% in the compound fertilizer, P 2 o 5 ≥8%, K 2 O≥18%.

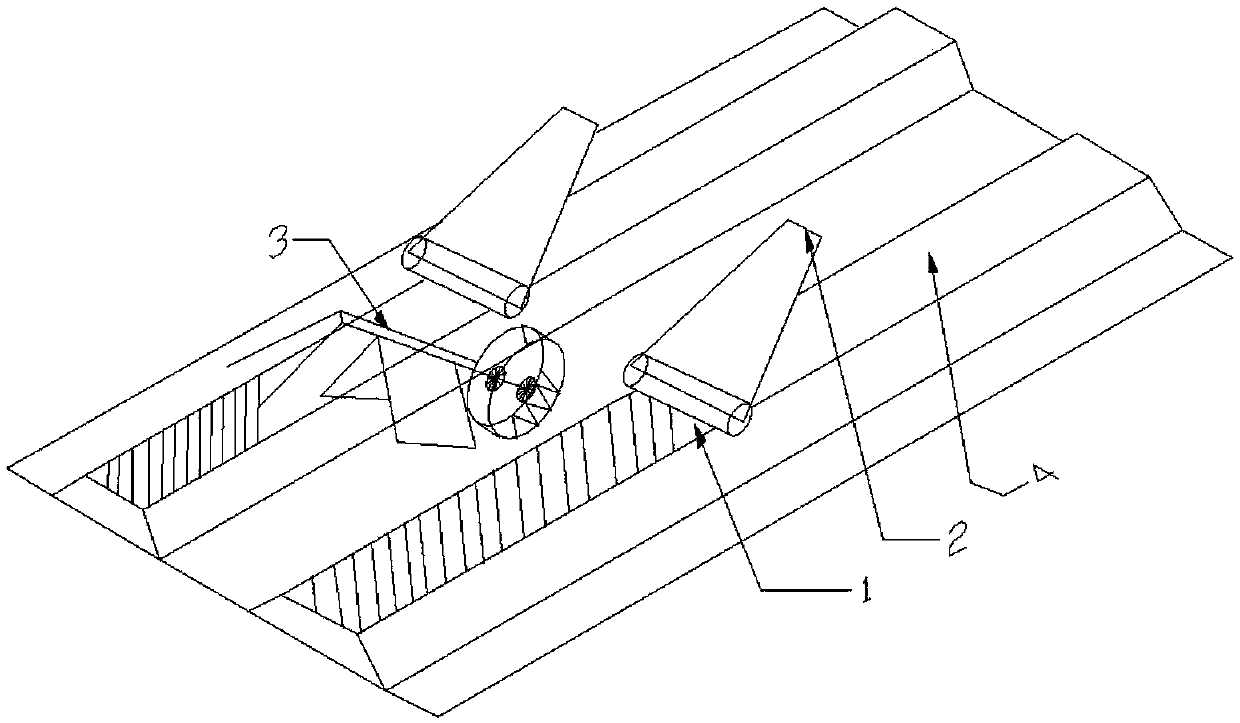

[0028] (2) Ridging, the width of the ridge surface is 80cm, the width of the ridge bottom is 100cm, the height of the ridge is 15cm, and the width of the ditch is 20cm, so as to ensure that the soil in the plow layer is finely divided and flat, and at the same time clean the root stubble on the ridge surface so as not to affect the quality of the film, otherwise it will biodegrade The weeding film cannot s...

Embodiment 2

[0035] (1) Site selection and site preparation: select the loose sandy loam field with sufficient water source and convenient irrigation, the previous crop is potato, fertilization: use chicken manure organic fertilizer 700kg, compound fertilizer 130kg; this compound fertilizer selects Sumisho compound fertilizer (16: 8:18), wherein the compound fertilizer contains N≥16%, P 2 o 5 ≥8%, K 2 O≥18%.

[0036] (2) Ridging, the width of the ridge surface is 80cm, the width of the ridge bottom is 100cm, the height of the ridge is 15cm, and the width of the ditch is 20cm, so as to ensure that the soil of the plow layer is finely divided and smooth, and at the same time, the root stubble on the surface of the ridge is cleaned so as not to affect the quality of the film covering;

[0037] (3) Sowing: sowing in the shape of "product" along the ridge surface successively, the sowing depth is 5cm, the bud eyes are facing down, the wound is facing up, the row spacing in the ridge is 20cm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com