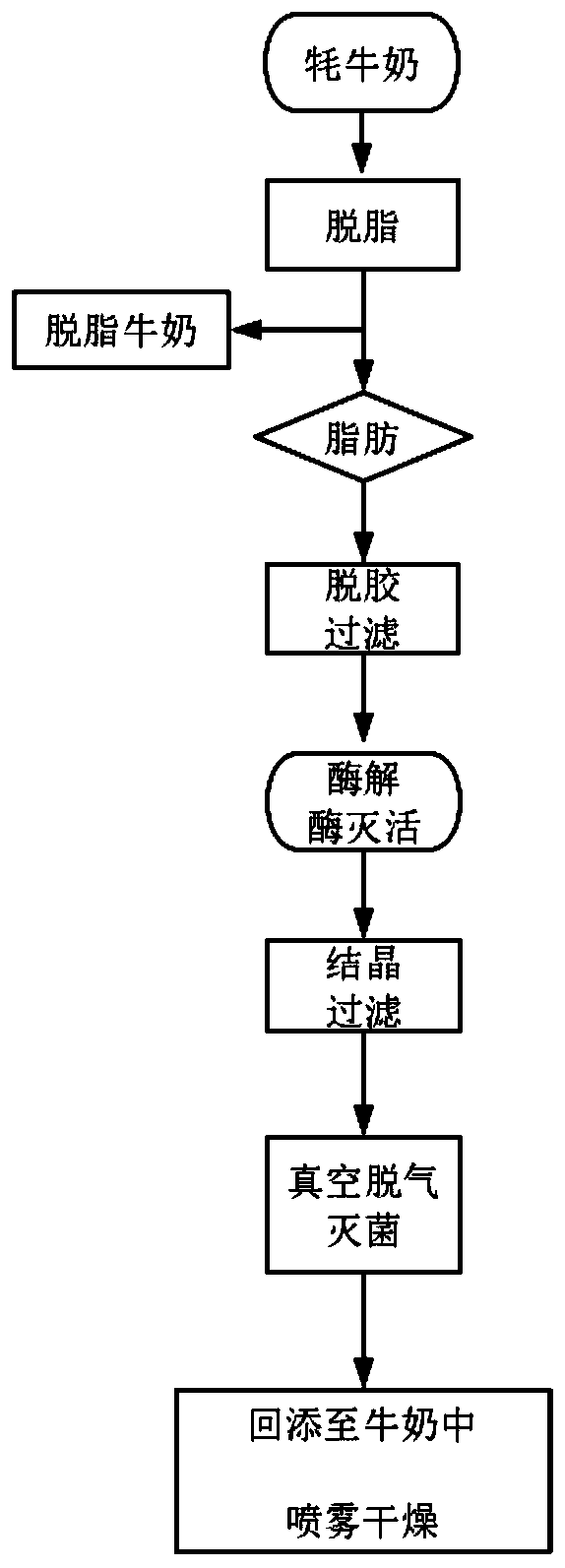

Production process of standardized yak-flavored milk

A production process and technology for yak milk, which are applied in milking devices, milk preparations, dairy products, etc., can solve the problems of unstandardized processing of yak milk flavor substances, and achieve the effects of high sensory score and improved utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A production process for standardized yak-flavored milk, comprising the steps of:

[0034] Step 1, defatting: Preheat yak milk in a container with a temperature of 30°C for at least 2 hours, let it stand for at least 30 minutes, and then separate it for 5 minutes through a separator with a rotating speed of 1000 rpm to obtain defatted yak milk and cream, wherein the defatted yak milk is recovered to obtain fat ready for use;

[0035] Step 2, degumming: wash the fat obtained in step 1 with purified water for at least 2 times, then put the fat into a container filled with purified water, add 30% phosphoric acid aqueous solution and place it at a temperature of 25°C Shake on a constant temperature shaker for at least 30 minutes. The mass ratio of phosphoric acid aqueous solution to fat is 1:0.8. After taking out and standing for at least 10 minutes, the oil layer and water layer are separated, and the water layer is separated and removed to obtain degummed fat for use;

...

Embodiment 2

[0040] A production process for standardized yak-flavored milk, comprising the steps of:

[0041] Step 1, degreasing: Preheat yak milk in a container with a temperature of 45°C for at least 2 hours, let it stand for at least 30 minutes, and then separate it through a separator with a rotating speed of 1500 rpm for 3 minutes to obtain defatted yak milk and cream, wherein the defatted yak milk is recovered to obtain fat ready for use;

[0042] Step 2, degumming: wash the fat obtained in step 1 with purified water for at least 2 times, then put the fat into a container filled with purified water, add 35% phosphoric acid aqueous solution and place it at a temperature of 25°C Shake on a constant temperature shaker for at least 30 minutes. The mass ratio of phosphoric acid aqueous solution to fat is 1:1.0. After taking out and standing for at least 10 minutes, the oil layer and water layer are separated, and the water layer is separated and removed to obtain degummed fat for use;

...

Embodiment 3

[0047] A production process for standardized yak-flavored milk, comprising the steps of:

[0048] Step 1, degreasing: Preheat yak milk in a container with a temperature of 35°C for at least 2 hours, let it stand for at least 30 minutes, and then separate it through a separator with a rotating speed of 1200 rpm for 4 minutes to obtain defatted yak milk and cream, wherein the defatted yak milk is recycled to obtain fat ready for use;

[0049] Step 2, degumming: wash the fat obtained in step 1 with purified water for at least 2 times, then put the fat into a container filled with purified water, add a phosphoric acid aqueous solution with a mass fraction of 32%, and place it at a temperature of 25°C Shake on a constant temperature shaker for at least 30 minutes. The mass ratio of phosphoric acid aqueous solution to fat is 1:0.9. After taking out and standing for at least 10 minutes, the oil layer and water layer are separated, and the water layer is separated and removed to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com