Underground net washing machine and net washing module and net washing method thereof

A net washing and net machine technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning hollow objects, etc., can solve the problem of inability to adjust the cleaning disc accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

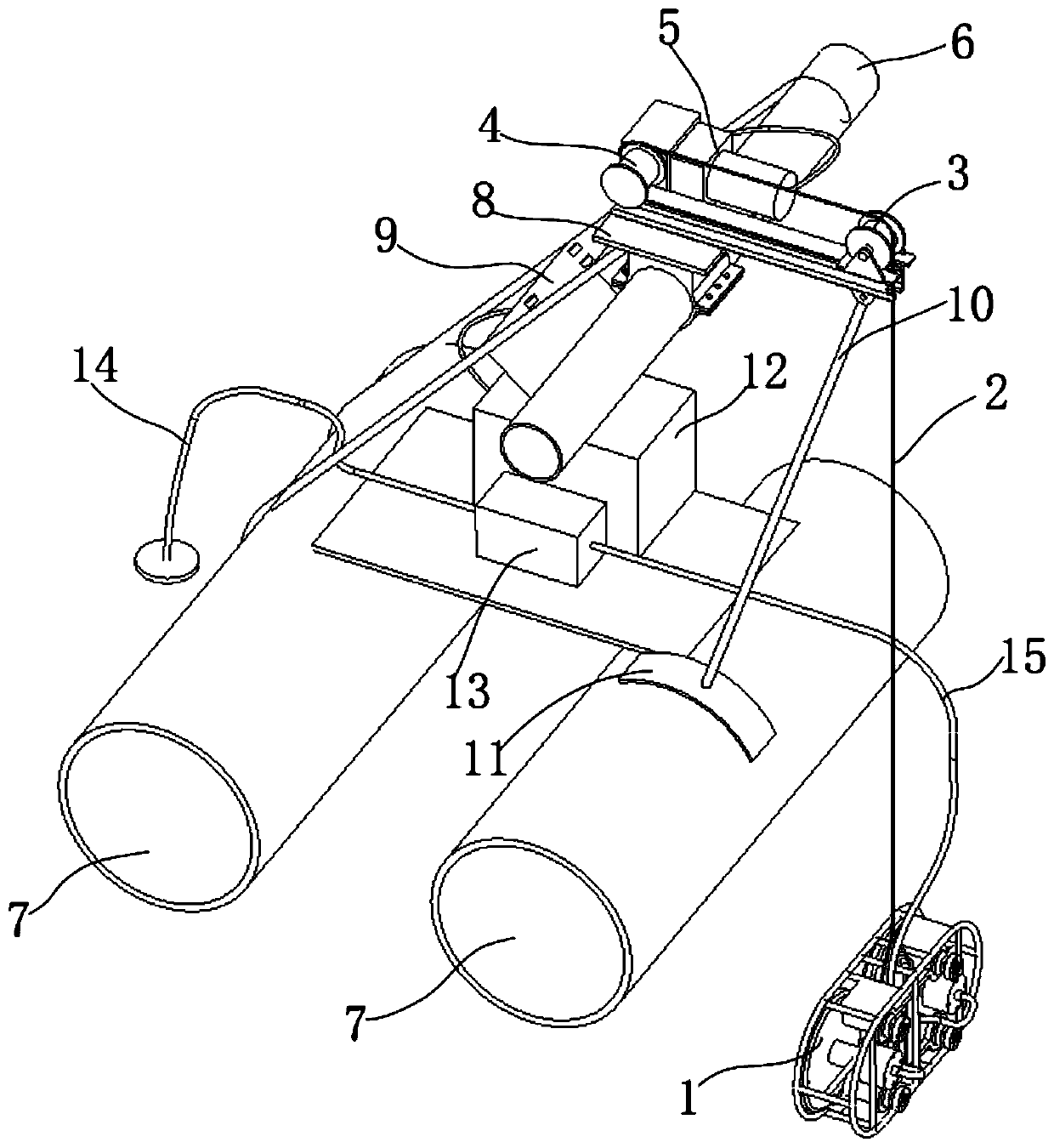

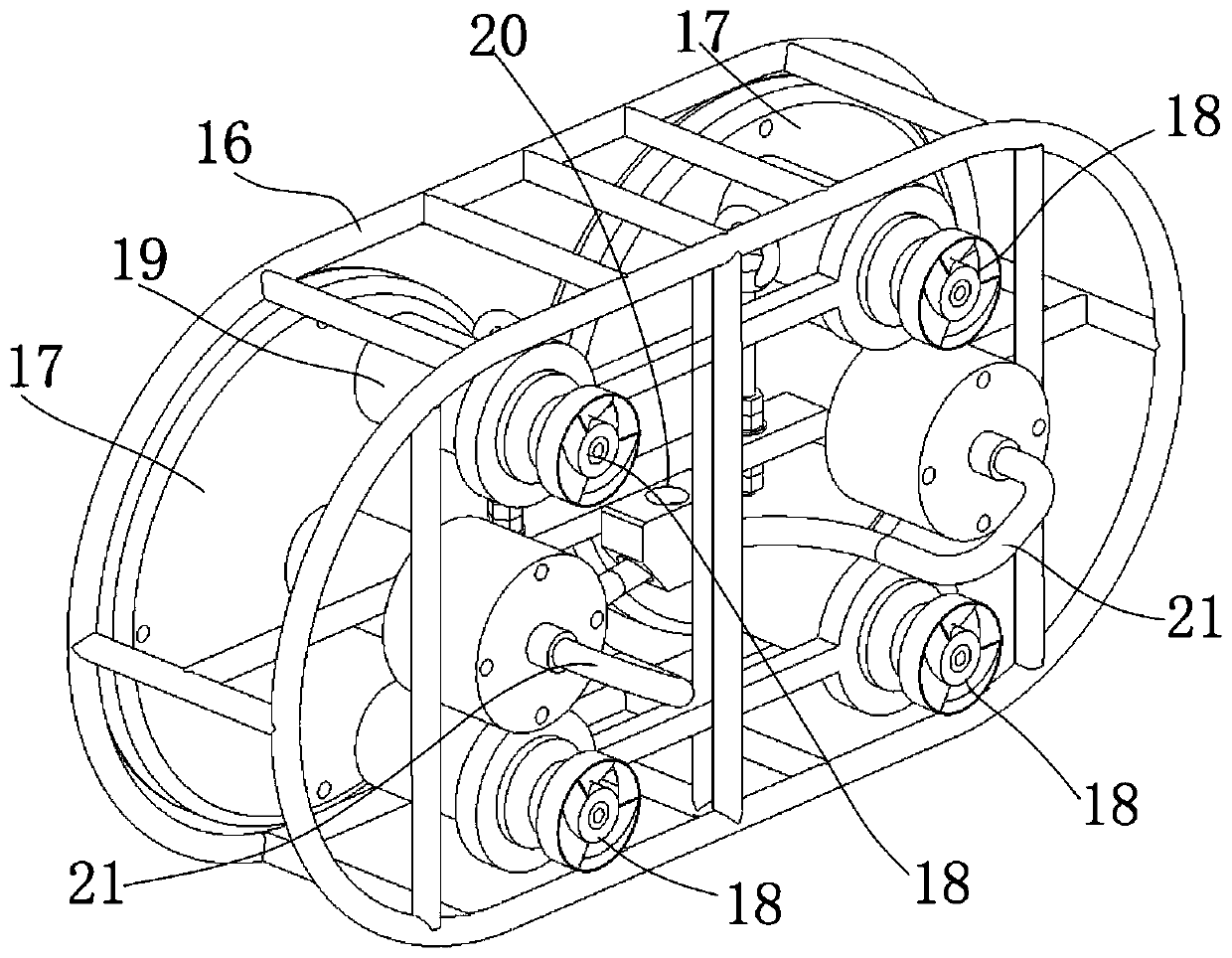

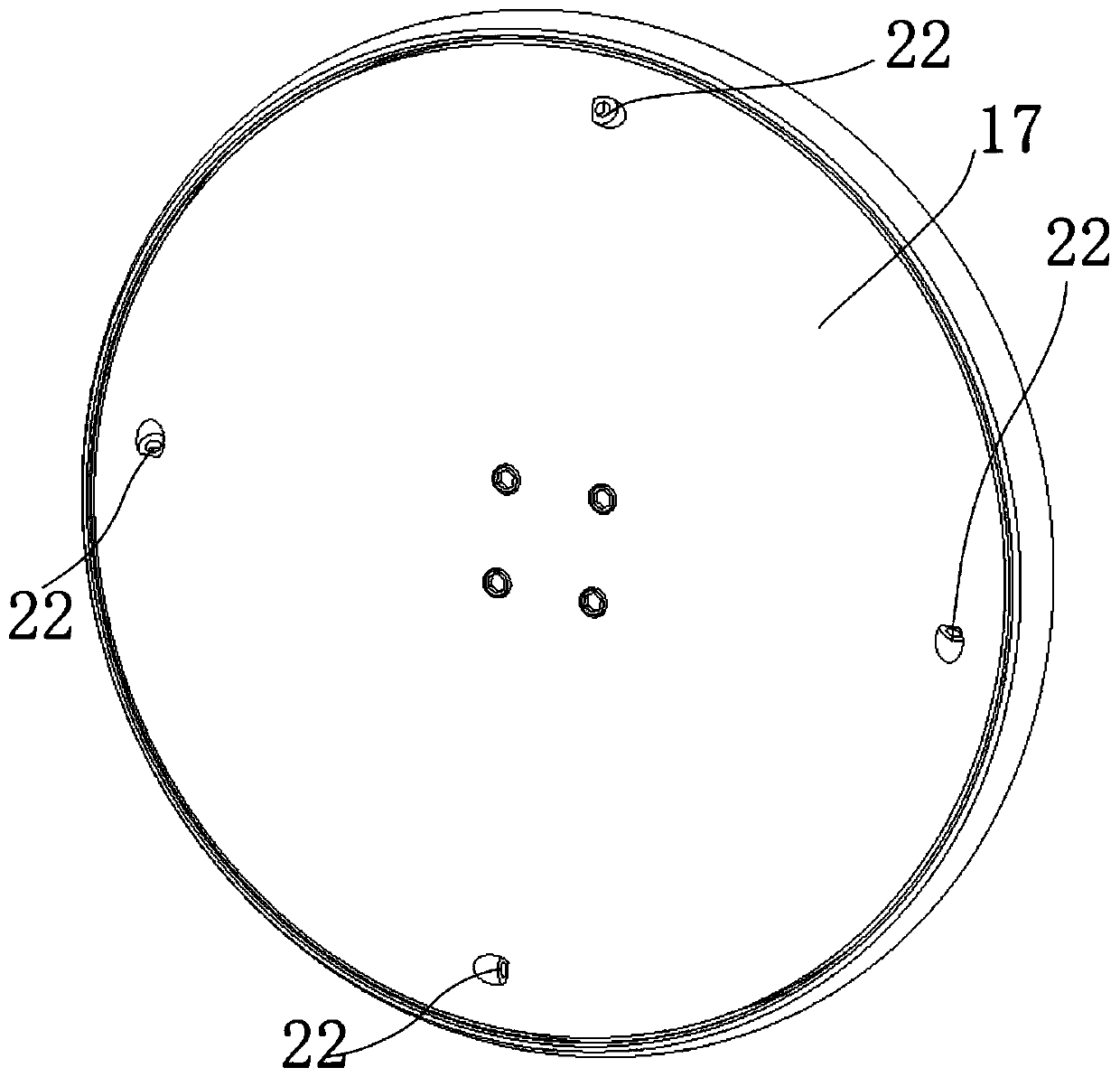

[0068] Such as figure 1 As shown, an underwater net washing machine includes a winding wheel 4 and a cable 2, one end of the cable 2 goes around the pulley 3 to connect to the net washing module 1, the other end of the cable 2 is wound on the winding wheel 4, and the The reel 4 is powered by a cable motor, and the cable motor, the rewinding wheel 4 and the pulley 3 are all fixedly mounted on the sliding mounting seat 8, and the sliding mounting seat 8 is installed on the handrail pipe 6, and the sliding mounting seat 8 is connected to the handrail pipe 6 is socketed and fixed by bolts. Loosening the bolts can make the fixed position of the sliding mounting seat 8 translate in the handrail tube 6; adjust the horizontal position of the entire device through translation, and then drive the net washing module 1 to translate underwater.

[0069] It also includes two main floating tubes 7 and an arc-shaped support plate 11, the two main floating tubes 7 are fixedly connected, one o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com