Preparation method of high-purity magnesium malate

A magnesium malate, high-purity technology, applied in carboxylate preparation, separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems of low purity of magnesium malate, high production cost, low chelation rate, etc. Achieve the effects of facilitating industrial production, increasing chelation rate, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

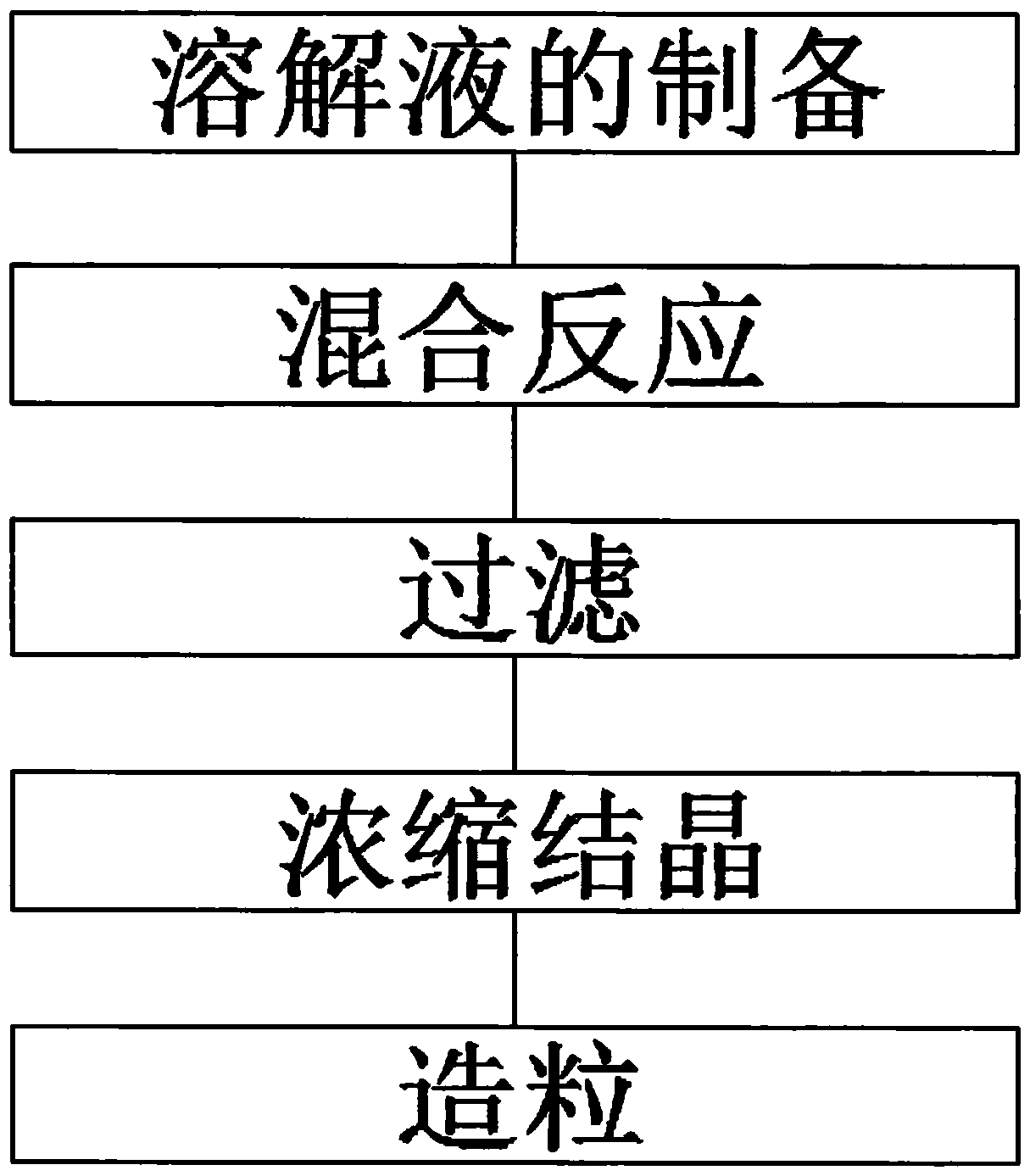

[0019] A kind of preparation method of high-purity magnesium malate, through the preparation of solution, mixed reaction, filtration, concentrated crystallization and granulation steps, complete the preparation of high-purity magnesium malate; Concrete steps are as follows:

[0020] (1) Preparation of dissolving solution: deionized water and DL-malic acid were mixed and dissolved to obtain a dissolving solution; the mixing mass ratio of deionized water and DL-malic acid was 100:1.

[0021] (2) Mixed reaction: heat the solution to 76°C, add magnesium oxide, continue to heat up to 112°C, and continue stirring until the magnesium oxide is completely dissolved to obtain a reaction solution; the mass ratio of magnesium oxide to the solution is 0.8:100.

[0022] (3) Filtration: the reaction solution is decolorized and filtered.

[0023] (4) Concentrated crystallization: the filtrate is concentrated and crystallized under reduced pressure to obtain magnesium malate crystals.

[0024...

Embodiment 2

[0026] A kind of preparation method of high-purity magnesium malate, through the preparation of solution, mixed reaction, filtration, concentrated crystallization and granulation steps, complete the preparation of high-purity magnesium malate; Concrete steps are as follows:

[0027] (1) Preparation of dissolving solution: deionized water and DL-malic acid were mixed and dissolved to obtain a dissolving solution; the mixing mass ratio of deionized water and DL-malic acid was 100:3.

[0028] (2) Mixed reaction: heat the solution to 80°C, add magnesium oxide, continue to heat up to 118°C, and continue stirring until the magnesium oxide is completely dissolved to obtain a reaction solution; the mass ratio of magnesium oxide to the solution is 1.2:100.

[0029] (3) Filtration: the reaction solution is decolorized and filtered.

[0030] (4) Concentrated crystallization: the filtrate is concentrated and crystallized under reduced pressure to obtain magnesium malate crystals.

[0031...

Embodiment 3

[0033] A kind of preparation method of high-purity magnesium malate, through the preparation of solution, mixed reaction, filtration, concentrated crystallization and granulation steps, complete the preparation of high-purity magnesium malate; Concrete steps are as follows:

[0034] (1) Preparation of dissolving solution: deionized water and DL-malic acid were mixed and dissolved to obtain a dissolving solution; the mixing mass ratio of deionized water and DL-malic acid was 100:2.

[0035] (2) Mixed reaction: heat the solution to 78°C, add magnesium oxide, continue to heat up to 115°C, and continue stirring until the magnesium oxide is completely dissolved to obtain a reaction solution; the mass ratio of magnesium oxide to the solution is 1.0:100.

[0036] (3) Filtration: the reaction solution is decolorized and filtered.

[0037] (4) Concentrated crystallization: the filtrate is concentrated and crystallized under reduced pressure to obtain magnesium malate crystals.

[0038...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com