Direct-current cable insulation material for suppressing space charge and preparation method of direct-current cable insulation material

A DC cable and space charge technology, which is applied in the field of DC cable insulation material and its preparation to suppress space charge, achieves good processing characteristics, avoids agglomeration, and is conducive to long-term start-up production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

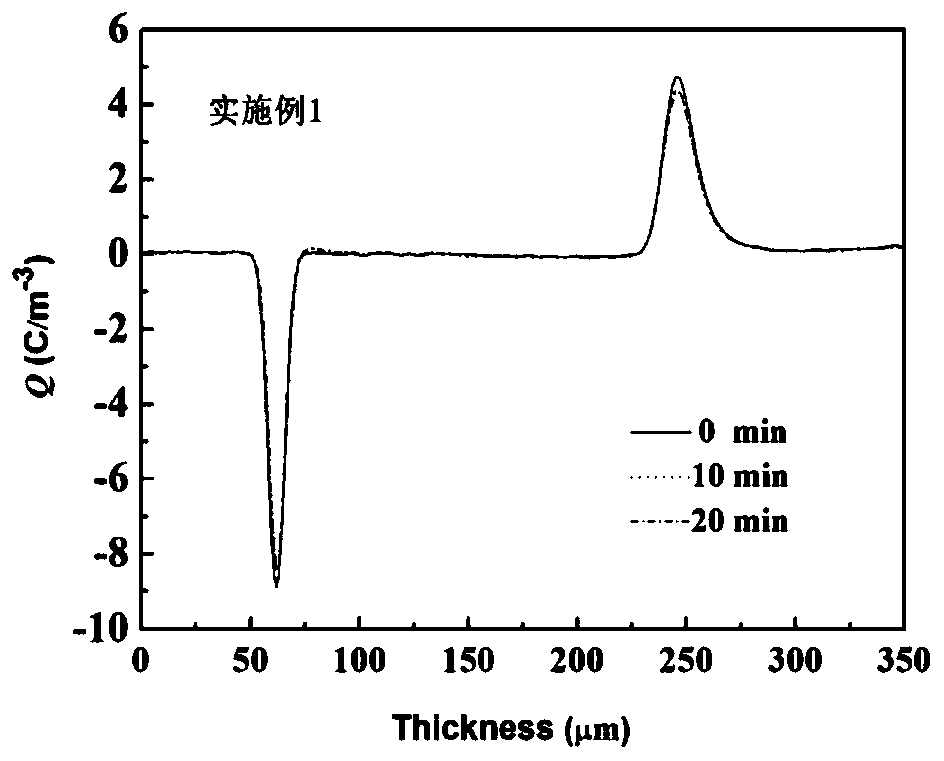

Embodiment 1

[0029] According to the weight ratio of 99:1:0.2, the low-density polyethylene, ethylene acrylic acid copolymer and antioxidant were added to the internal mixer, melted and kneaded at 130°C for 15 minutes, and the obtained material was melted in a single-screw extruder. Extrusion, the extrusion temperature is 160°C, the screw speed is 220r / min, the molten material is filtered through a 500-mesh screen and extruded through the die, cooled and granulated; then the post-absorption technology will be used according to a certain ratio of 100:1.6 The peroxide cross-linking agent and the obtained material particles are mixed and absorbed at a temperature of 80° C., kept warm until the cross-linking agent is completely absorbed, and then cooled to room temperature to prepare a pre-cross-linked insulating material.

Embodiment 2

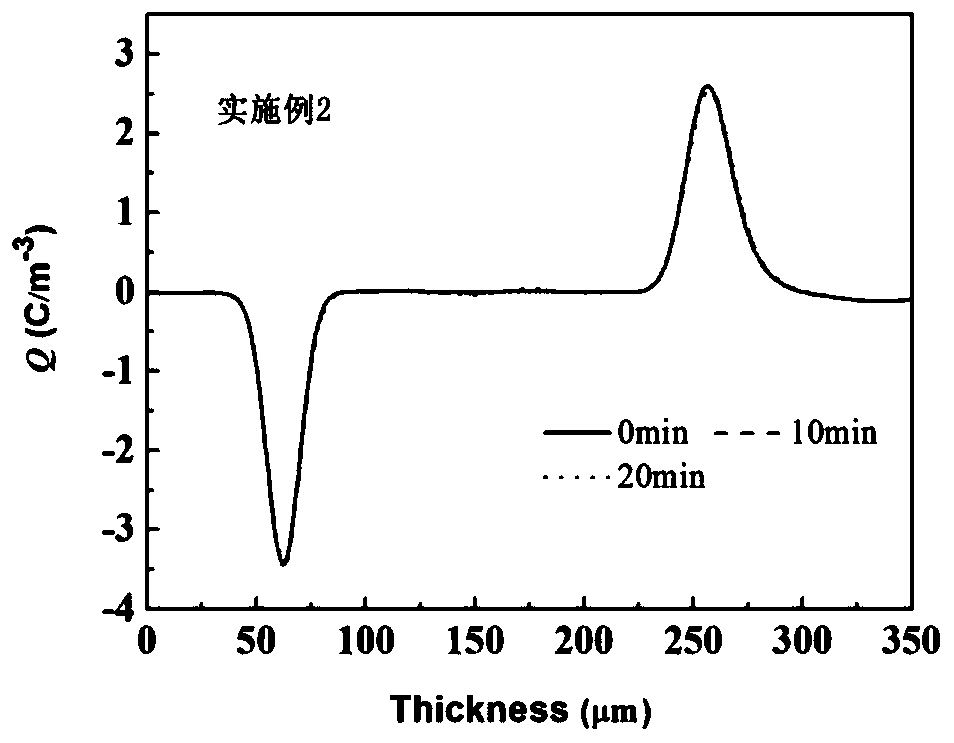

[0031] According to the weight ratio of 98:2:0.15, the low-density polyethylene, ethylene acrylic acid copolymer and antioxidant were added to the internal mixer, melted and kneaded at 125°C for 14 minutes, and the obtained material was melted in a single-screw extruder. Extrusion, the extrusion temperature is 165°C, the screw speed is 200r / min, the molten material is filtered through a 500-mesh screen and then extruded through the die head, cooled and granulated; then the post-absorption technology will be used according to a certain ratio of 100:1.8 The peroxide cross-linking agent and the obtained material particles are mixed and absorbed at a temperature of 70° C., kept warm until the cross-linking agent is completely absorbed, and then cooled to room temperature to prepare a pre-cross-linked insulating material.

Embodiment 3

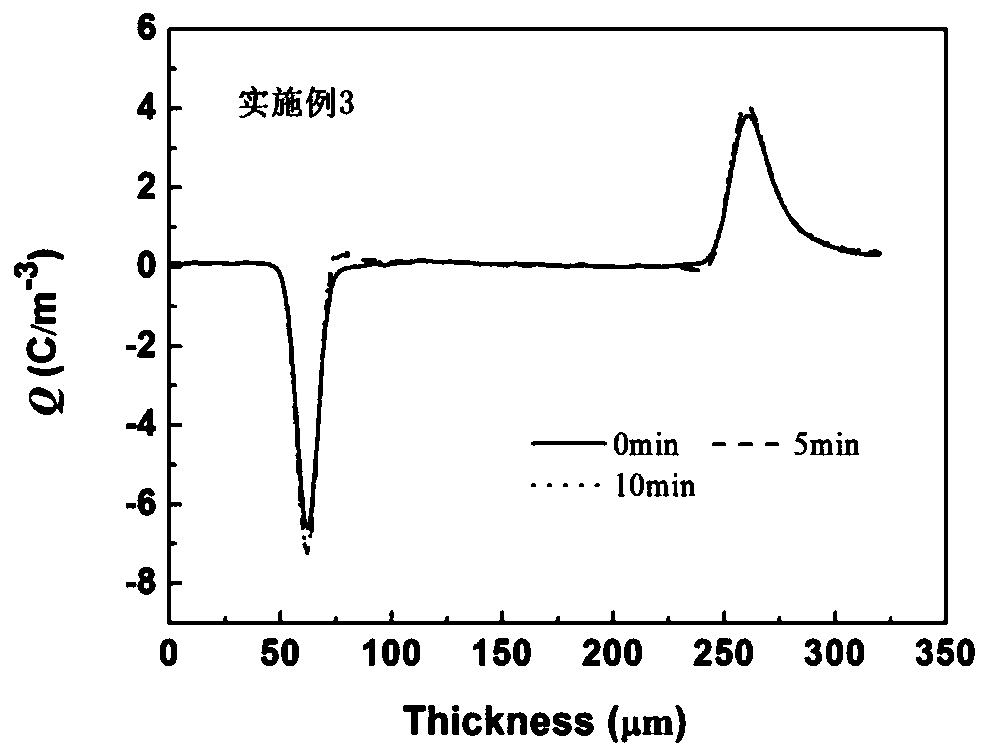

[0033] According to the weight ratio of 97:3:0.25, the low-density polyethylene, ethylene acrylic acid copolymer and antioxidant were added to the internal mixer, melted and kneaded at 120°C for 15 minutes, and the obtained material was melted in a single-screw extruder. Extrusion, the extrusion temperature is 160°C, the screw speed is 250r / min, the molten material is filtered through a 500-mesh screen, and then extruded from the die, cooled and granulated; then the post-absorption technology will be used according to a certain ratio of 100:1.7 The peroxide cross-linking agent and the obtained material particles are mixed and absorbed at a temperature of 75° C., kept warm until the cross-linking agent is completely absorbed, and then cooled to room temperature to prepare a pre-cross-linked insulating material.

[0034] Figure 1-Figure 3 It is the space charge distribution diagram of the embodiment of the present invention under the 30kV / mm DC field. It can be seen from the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com