Fast drying and cooling foil production device

A rapid drying, drying and cooling technology, applied in drying, drying machine, drying gas arrangement, etc., can solve problems such as rapid drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

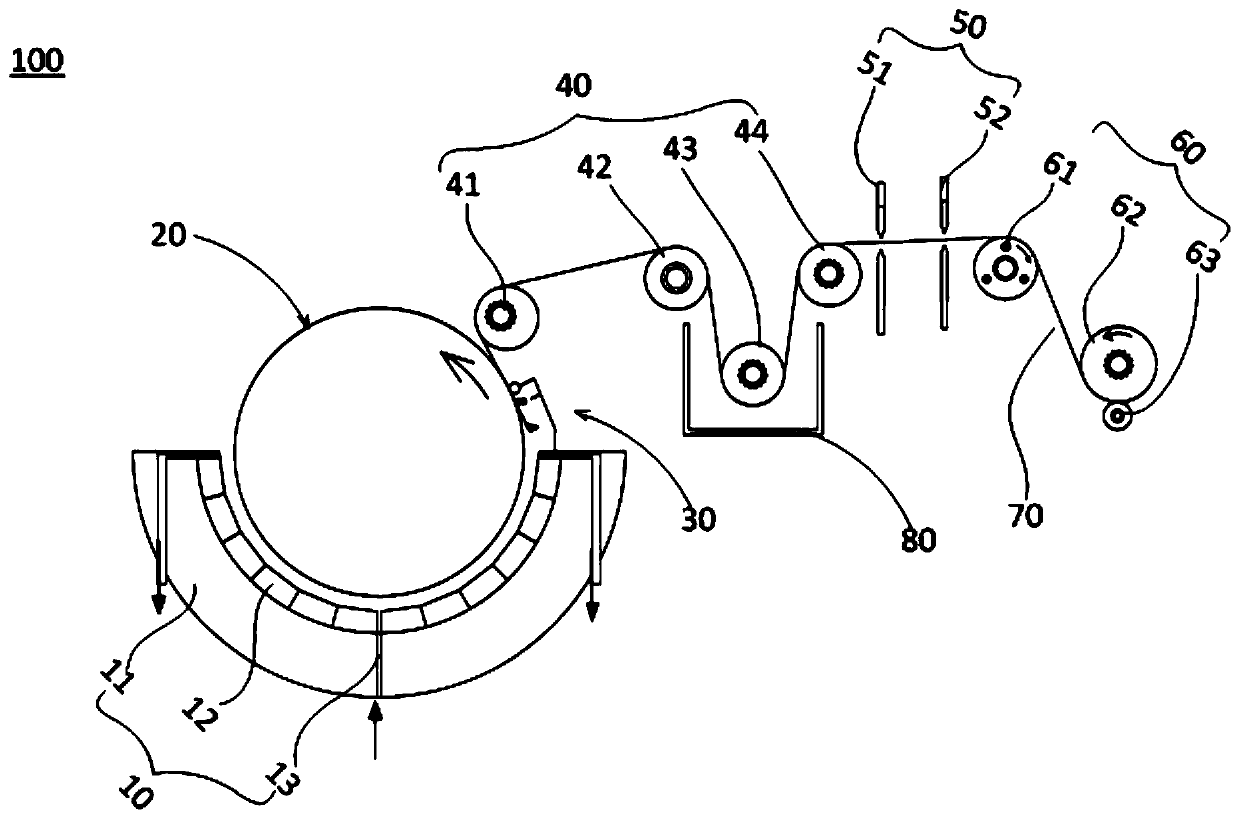

Method used

Image

Examples

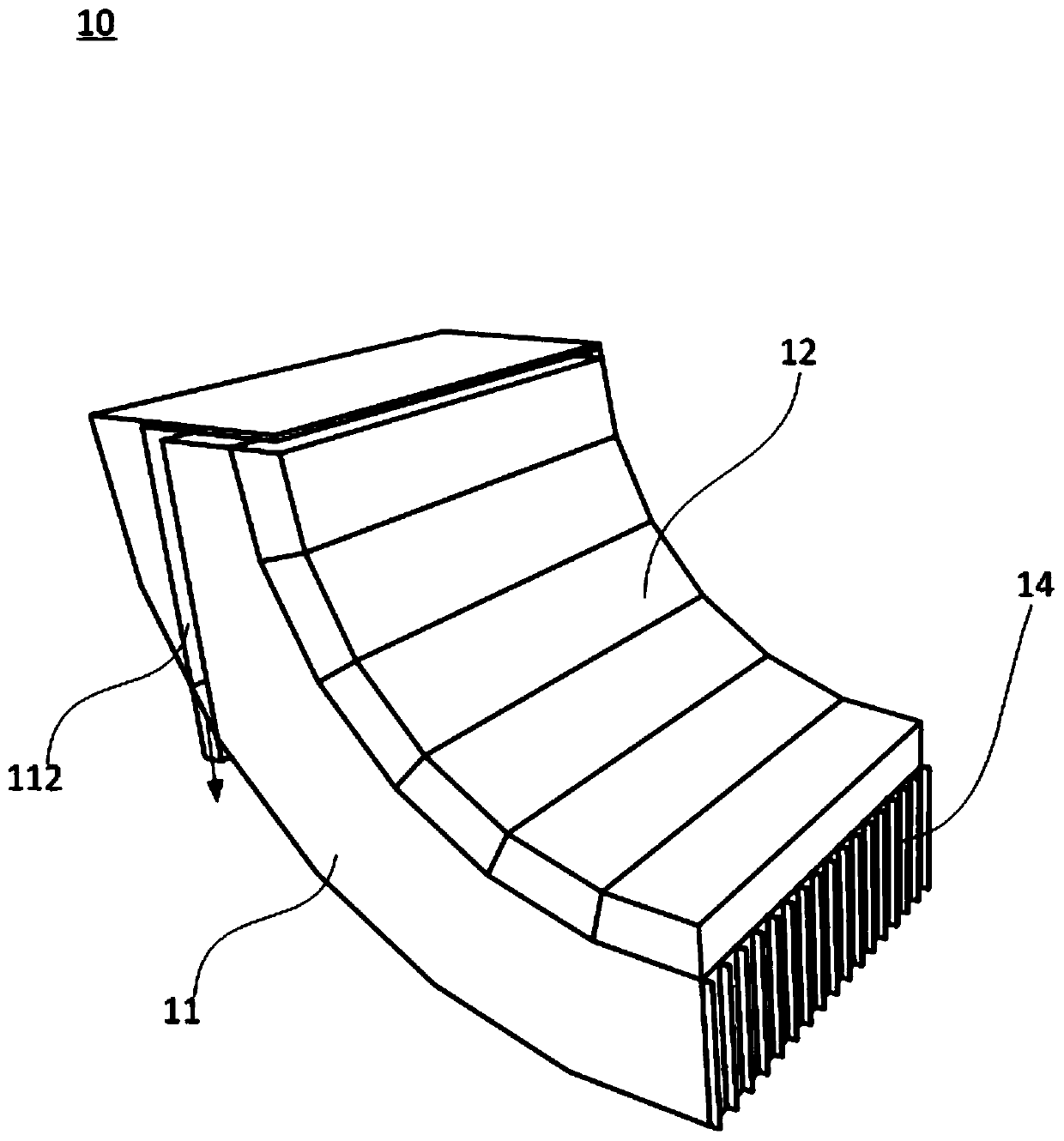

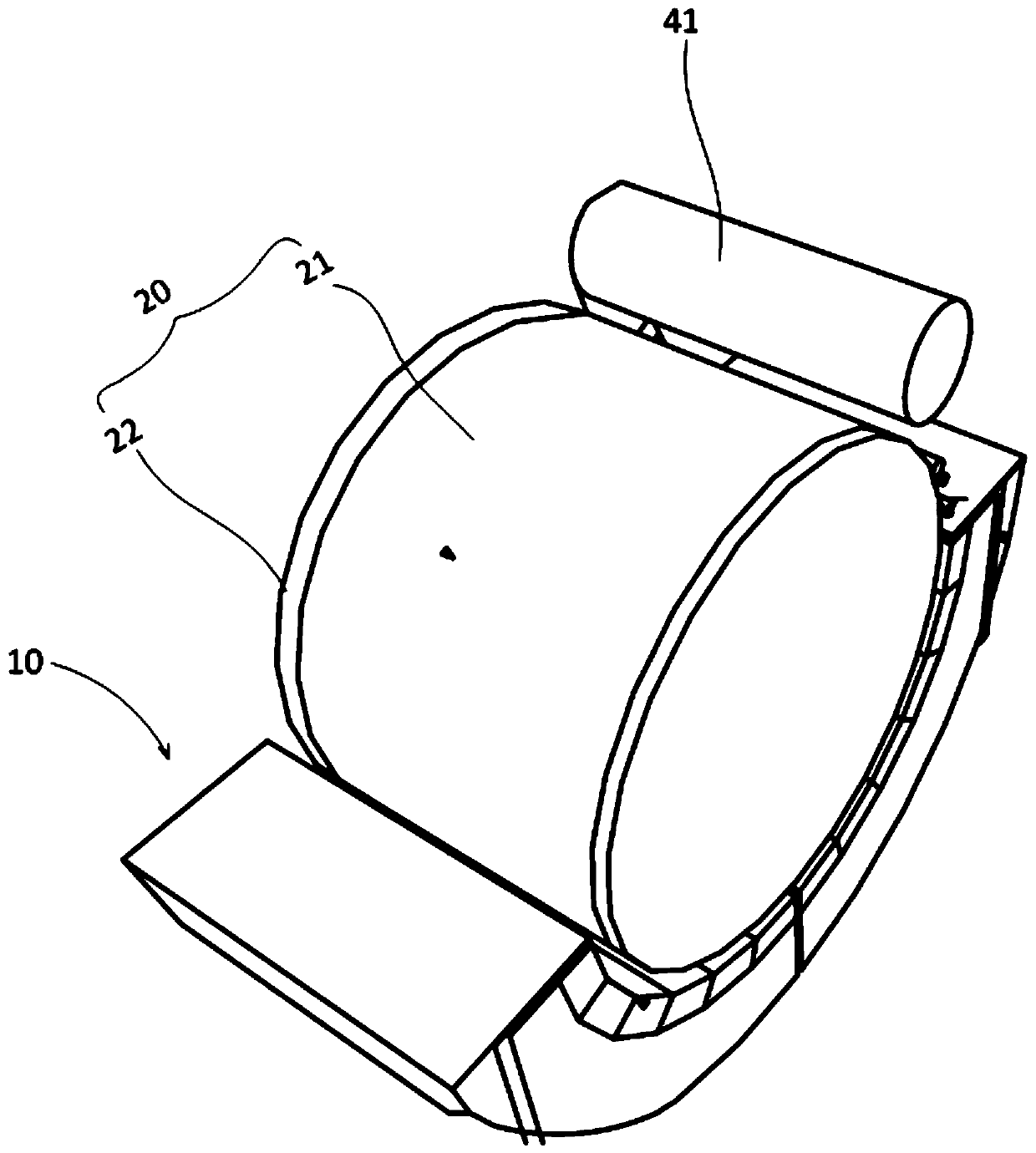

preparation example Construction

[0047] Please refer to Figure 7 , the present invention also provides a preparation method of electrolytic copper foil, comprising the following steps:

[0048] S4, copper sulfate electrolyte configuration: heat and dissolve high-purity copper wires with a purity of 99.95% and above in sulfuric acid solution to generate copper sulfate electrolyte;

[0049] S5, raw foil manufacturing; add additives to the copper sulfate electrolyte, and transport it to the electrolytic cell of the foil machine for electrolytic raw foil, wherein; the process parameters of electrolytic raw foil are: the temperature of the electrolytic solution is controlled at 50-60 °C, the current density of the anode plate 12 during the foil production process is 38-45A / dm 2 , Cu 2+ Concentration is 90~95g / L, H 2 SO 4 Concentration is 100-110g / L, gelatin concentration is 100-300ppm, ceric sulfate concentration is 0.5-10ppm, MESS concentration is 1-20ppm, SPS concentration is 10-50ppm, Cl - The concentrati...

Embodiment

[0062] Example: heating and dissolving a high-purity copper wire with a purity of 99.95% in a sulfuric acid solution to form a copper sulfate electrolyte; adding additives to the copper sulfate electrolyte, and transporting it to the electrolytic cell of a foil production machine for electrolytic foil production. Among them; the process parameters of electrolytic raw foil are: the temperature of the electrolyte is controlled at 58 ° C, Cu 2+ Concentration is 94g / L, H 2 SO 4 Concentration is 106g / L, gelatin concentration is 150ppm, ceric sulfate concentration is 4ppm, MESS concentration is 12ppm, SPS concentration is 25ppm, Cl - The concentration is 28ppm; copper foils of 4 microns, 4.5 microns, 5 microns and 6 microns are respectively obtained by controlling the current density of the anode plate during the foil production process. The test data of various copper foils are as follows:

[0063]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com