Light-homogenized rod and illuminating system

A technology of uniform light rod and rod body, applied in the field of optics, can solve the problems of increased difficulty, increased volume and length of the illumination optical system, and achieves the effect of simplifying adjustment difficulty, enhancing the uniform light effect, and shortening the length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

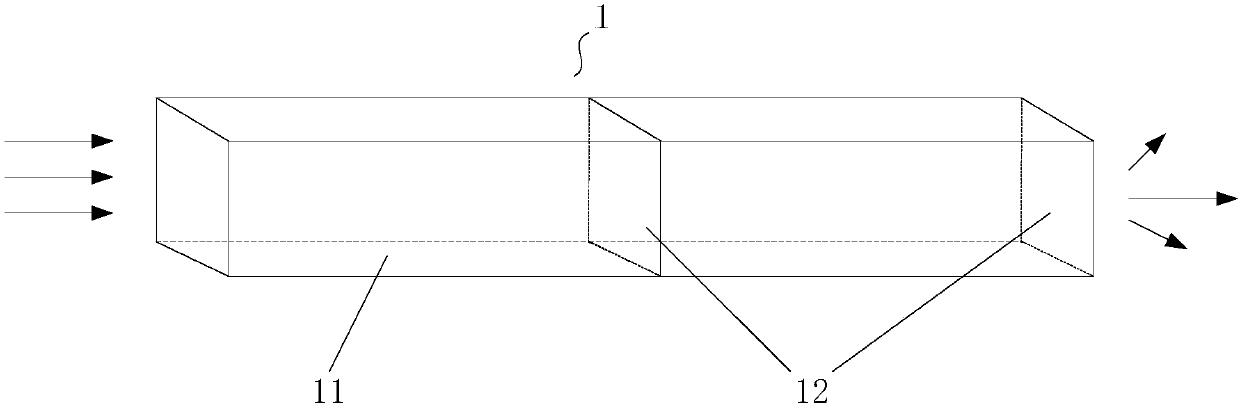

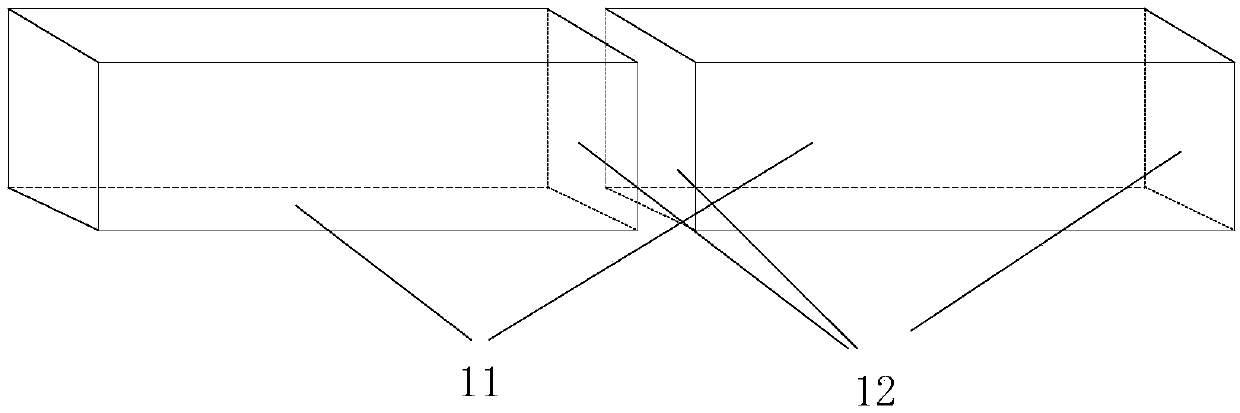

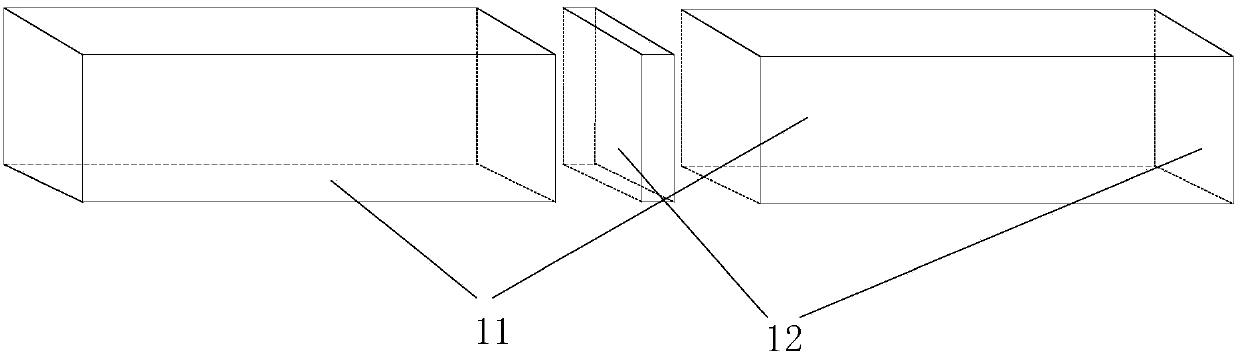

Embodiment 1

[0031] This embodiment provides a dodging rod with a diffractive layer. The dodging rod is a solid rod body or a hollow rod body whose inner wall is coated with a reflective film. The diffractive layer includes one or more, and the diffractive layer is arranged on the middle part or the end face of the dodging rod, or is arranged on the middle part and the end face of the dodging rod at the same time, preferably, the end face provided with the diffractive layer is the light emitting surface of the dodging rod. There is a diffraction pattern on the diffraction layer, and the diffraction pattern is mainly a diffraction hole, which diffracts light at different incident angles through multiple diffraction holes, which improves the uniformity of the light emitted by the homogenizing rod, and at the same time makes the energy distribution of the laser beam tend to be uniform , no longer tends to a Gaussian distribution. The diffraction layer makes the laser diffract during the tran...

Embodiment 2

[0042] This embodiment provides a lighting system including the light uniform rod of the first embodiment above. The lighting system also includes optical components such as a light source and a lighting mirror group. The lighting system with the above light uniform rod can emit better uniform light. In this embodiment, as Figure 8 The illustrated lighting system is described as an example. In other embodiments, the lighting system may include other optical components on the basis of the above-mentioned dodging rod 1 .

[0043] Such as Figure 8 As shown, the lighting system of this embodiment includes a light source 2 , a homogenizing rod 1 , a condenser lens 3 , an illuminating lens group 4 and a microscope objective lens 5 from top to bottom.

[0044]The light source 2 includes a laser and an optical fiber connected thereto, and the laser emits laser light through the optical fiber. The light source 2 can emit laser light of one wavelength or multiple wavelengths, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com