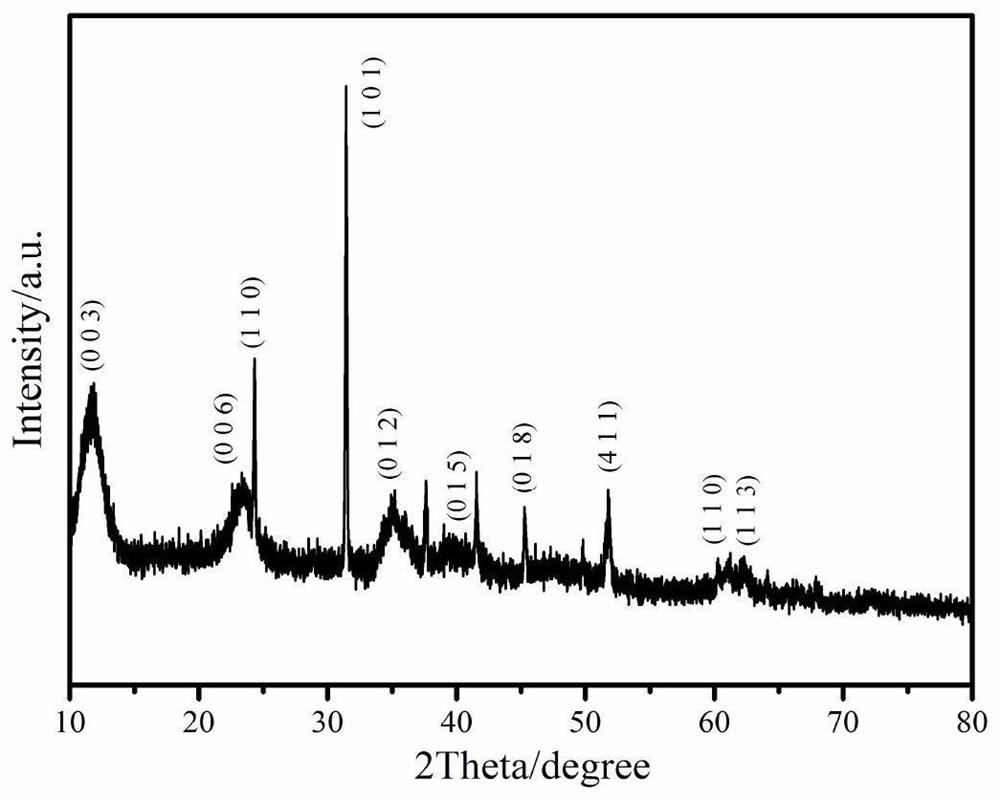

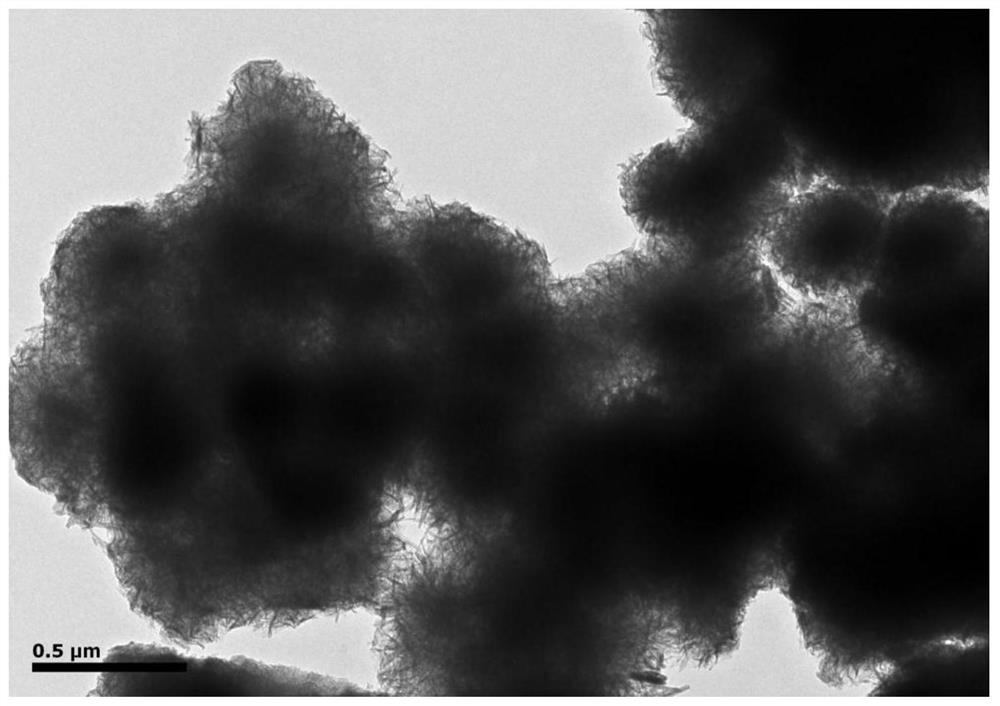

A spherical core-shell structure c@mno 2 @nial-ldh nanocomposites and methods for their preparation

A nanocomposite, core-shell structure technology, applied in the field of nanomaterial preparation, can solve the problems of poor stretchability, limited application, weakened rate performance, etc., achieve the effect of extremely repeatable, increase binding sites, and improve specific capacitance properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

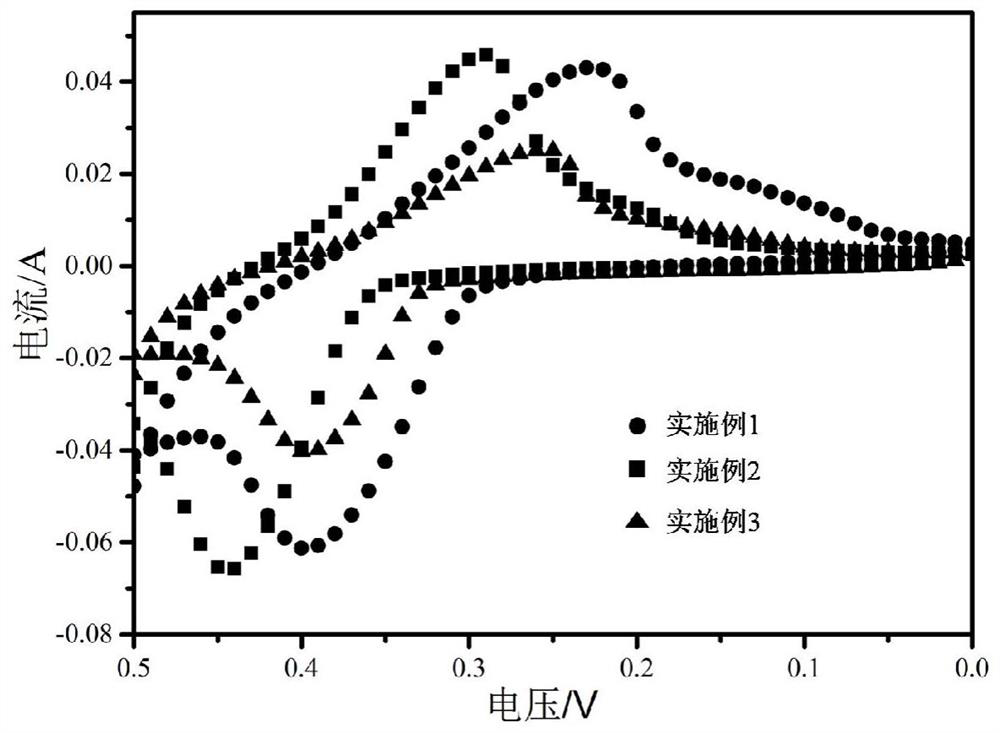

Embodiment 1

[0026] A spherical core-shell structure of C@MnO 2 The preparation method of @NiAl-LDH nanocomposite comprises the following steps:

[0027] (1) Preparation of C ball

[0028] Ultrasonically disperse 7.2g of glucose in 80mL of deionized water to form a homogeneous solution, then transfer it to a stainless steel reactor, and react in an oven at 180°C for 6h; Wash three times and dry in a vacuum oven at 80°C for 12 hours to obtain C balls;

[0029] (2) Preparation of C@MnO 2 composite material

[0030] Ultrasonic disperse 1.0 g of C spheres in 70 mL of deionized water, then add 0.5 g of KMnO 4 and stir evenly; transfer the obtained solution to a stainless steel reaction kettle, and react in a 120°C oven for 12 hours; after the reaction is completed, naturally cool to room temperature, and the obtained product is alternately washed three times with deionized water and absolute ethanol, and dried in a vacuum oven at 80°C for 12 hours , get C@MnO 2 composite materials;

[00...

Embodiment 2

[0035] A spherical core-shell structure of C@MnO 2 The preparation method of @NiAl-LDH nanocomposite comprises the following steps:

[0036] (1) Preparation of C ball

[0037] Same as Example 1.

[0038] (2) Preparation of C@MnO 2 composite material

[0039] Same as Example 1.

[0040] (3) Preparation of C@MnO 2 @NiAl-LDH nanocomposite

[0041] 0.131g nickel nitrate hexahydrate and 0.085g aluminum nitrate nonahydrate were completely dissolved in 25mL deionized water to form solution A; 0.1g C@MnO 2 Composite material, 0.043g Na 2 CO 3 and 0.063g NaOH were completely dissolved in 25mL deionized water to form solution B; solution A was added dropwise to solution B with constant stirring; the resulting suspension was transferred to a stainless steel reactor and reacted in an oven at 120°C for 6h; the reaction was completed After that, it was naturally cooled to room temperature, and the obtained product was alternately washed three times with deionized water and absolute...

Embodiment 3

[0044] A spherical core-shell structure of C@MnO 2 The preparation method of @NiAl-LDH nanocomposite comprises the following steps:

[0045] (1) Preparation of C ball

[0046] Same as Example 1.

[0047] (2) Preparation of C@MnO 2 composite material

[0048] Same as Example 1.

[0049] (3) Preparation of C@MnO 2 @NiAl-LDH nanocomposite:

[0050] 0.524g nickel nitrate hexahydrate and 0.338g aluminum nitrate nonahydrate were completely dissolved in 25mL deionized water to form solution A; 0.1g C@MnO 2 Composite material, 0.170g Na 2 CO 3 and 0.252g NaOH were completely dissolved in 25mL deionized water to form solution B; solution A was added dropwise to solution B with constant stirring; the resulting suspension was transferred to a stainless steel reactor and reacted in an oven at 120°C for 6h; the reaction was completed After that, it was naturally cooled to room temperature, and the obtained product was alternately washed three times with deionized water and absolut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com