Coal water slurry additive containing phosphate groups and preparation method thereof

A technology for coal-water slurry and additives, which is applied in the direction of liquid carbonaceous fuel, petroleum industry, fuel, etc., can solve the problems of poor slurry performance, low price, low slurry concentration, etc., to improve performance, easy control of conditions, and production. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

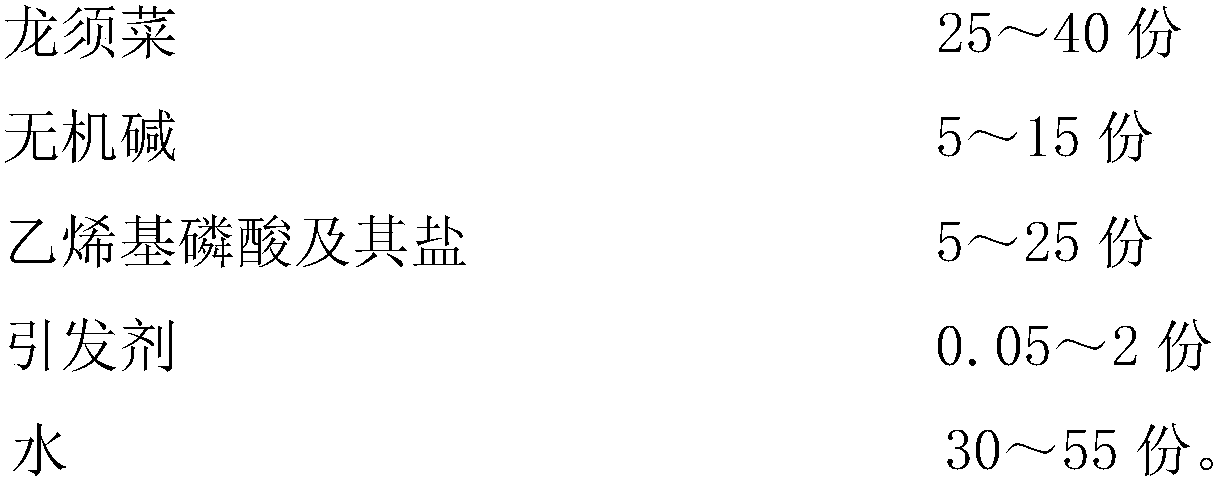

[0032] A kind of phosphoric acid group-containing coal-water slurry additive of the present invention is made of the following raw material components in proportions by mass:

[0033]

[0034] A kind of preparation method of the coal-water slurry additive containing phosphoric acid group of the present invention, realizes by following steps:

[0035] (1) After crushing 28 parts of asparagus into powder, add 35 parts of water to fully mix, stir evenly, gelatinize for 4 minutes under microwave radiation power of 260W, and cool to room temperature;

[0036] (2) Add the above-mentioned gelatinized asparagus into the reaction kettle, then add 11 parts of sodium hydroxide and 6 parts of vinyl phosphoric acid into the reaction kettle, start stirring and raise the temperature, and start adding dropwise after the temperature rises to 90°C A sodium persulfate solution with a mass percentage concentration of 5%, which is prepared from 1 part of sodium persulfate and 19 parts of water;...

Embodiment 2

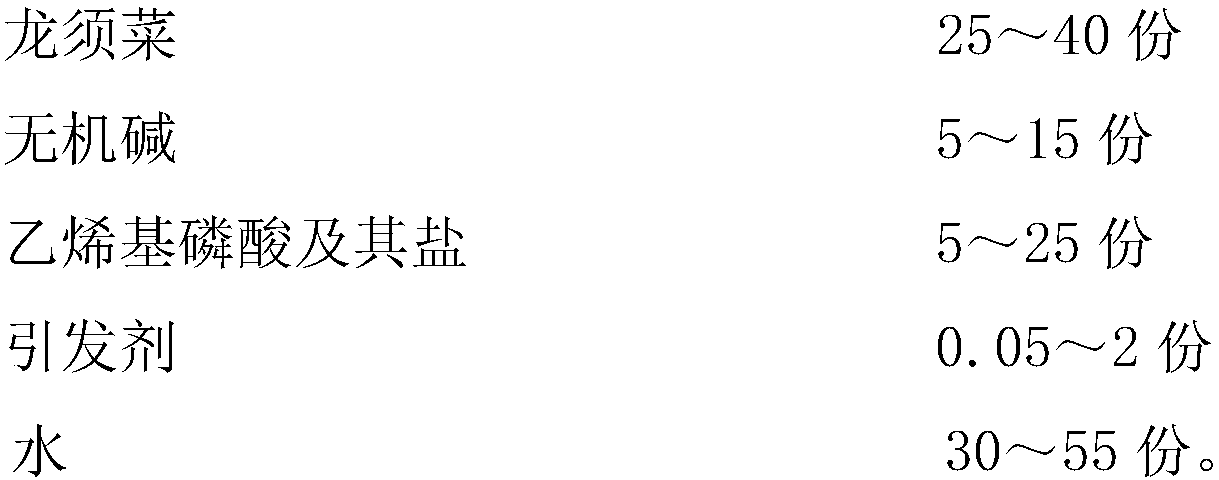

[0039] A kind of phosphoric acid group-containing coal-water slurry additive of the present invention is made of the following raw material components in proportions by mass:

[0040]

[0041] A kind of preparation method of the coal-water slurry additive containing phosphoric acid group of the present invention, realizes by following steps:

[0042] (1) After crushing 29 parts of asparagus into powder, add 33 parts of water to fully mix, stir evenly, gelatinize under microwave radiation power of 300W for 4.5 minutes, and cool to room temperature;

[0043] (2) Add the above-mentioned gelatinized asparagus into the reaction kettle, then add 9 parts of sodium hydroxide and 9 parts of vinyl phosphoric acid into the reaction kettle, start stirring and heat up, and start dripping after the temperature rises to 95°C Add a sodium persulfate solution with a concentration of 4% by mass, which is prepared from 0.8 parts of sodium persulfate and 19.2 parts of water; the time for addin...

Embodiment 3

[0046] A kind of phosphoric acid group-containing coal-water slurry additive of the present invention is made of the following raw material components in proportions by mass:

[0047]

[0048] A kind of preparation method of the coal-water slurry additive containing phosphoric acid group of the present invention, realizes by following steps:

[0049] (1) After crushing 30 parts of asparagus into powder, add 30 parts of water to fully mix, stir evenly, gelatinize under microwave radiation power of 300W for 4.5 minutes, and cool to room temperature;

[0050] (2) Add the above-mentioned gelatinized asparagus into the reaction kettle, then add 7 parts of sodium hydroxide and 13 parts of sodium vinyl phosphate into the reaction kettle, start stirring and raise the temperature, and start after the temperature rises to 100°C Add dropwise the potassium persulfate solution whose mass percent concentration is 6%, and this potassium persulfate solution is prepared by 1.2 parts of pota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com