Preparation method for special flavor natural milk aroma base material and natural milk aroma base material

A milk-flavored, natural technology, applied in the field of natural milk-flavored base material and the preparation of flavored natural milk-flavored base material, can solve the problems of high aroma intensity and low general application ability, and achieve the effect of improving aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A method for preparing a flavor natural milk flavor base, the preparation method comprising the following steps:

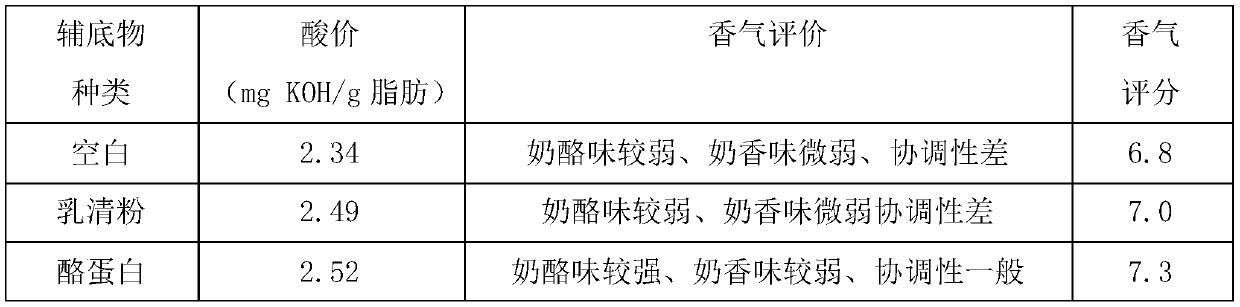

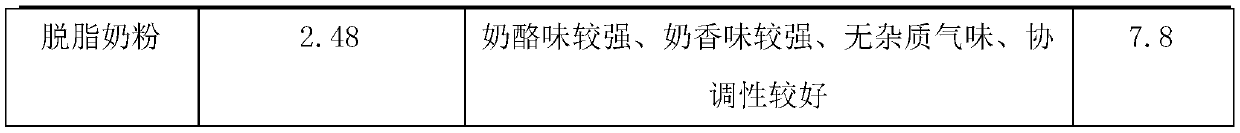

[0031] 1) Put the substrate of the milk flavor base and the auxiliary substrate in a glass container in sequence, and stir evenly to make a mixed liquid after mixing;

[0032] 2) Sterilize the mixture at a temperature of 75°C for 15-25min;

[0033] 3) After sterilization, cool the mixture to 35°C-45°C, add lipase, then place it in a shaking incubator, and perform enzymatic hydrolysis at 44°C-46°C, 120-130r / min , The time is 5-12h;

[0034] 4) Put the enzymolysis product after enzymolysis in a constant temperature water bath at 90℃ to inactivate the enzyme for 8-12min;

[0035] 5) After cooling the inactivated product to 35-45℃, add protease, place it in a shaking incubator, and carry out enzymolysis at 44℃-46℃, 120-130r / min, time is 5 -12h;

[0036] 6) Put the enzymolysis product after enzymolysis in a constant temperature water bath at 90℃ to inactivate the enzyme ...

Embodiment 1

[0041] A natural milk flavor base prepared by a method for preparing a flavored natural milk flavor base. The natural milk flavor base is prepared as a light cheese flavor natural milk flavor base by the following raw material components: unsalted butter, skimmed milk powder, Lipase MER, protease AX, ethyl maltol, vanillin;

[0042] The specific steps include:

[0043] A1. Select the mass ratio of raw material components:

[0044] Unsalted butter: Based on 100 parts of unsalted butter, the unsalted butter is preferred as Dumeixian unsalted butter;

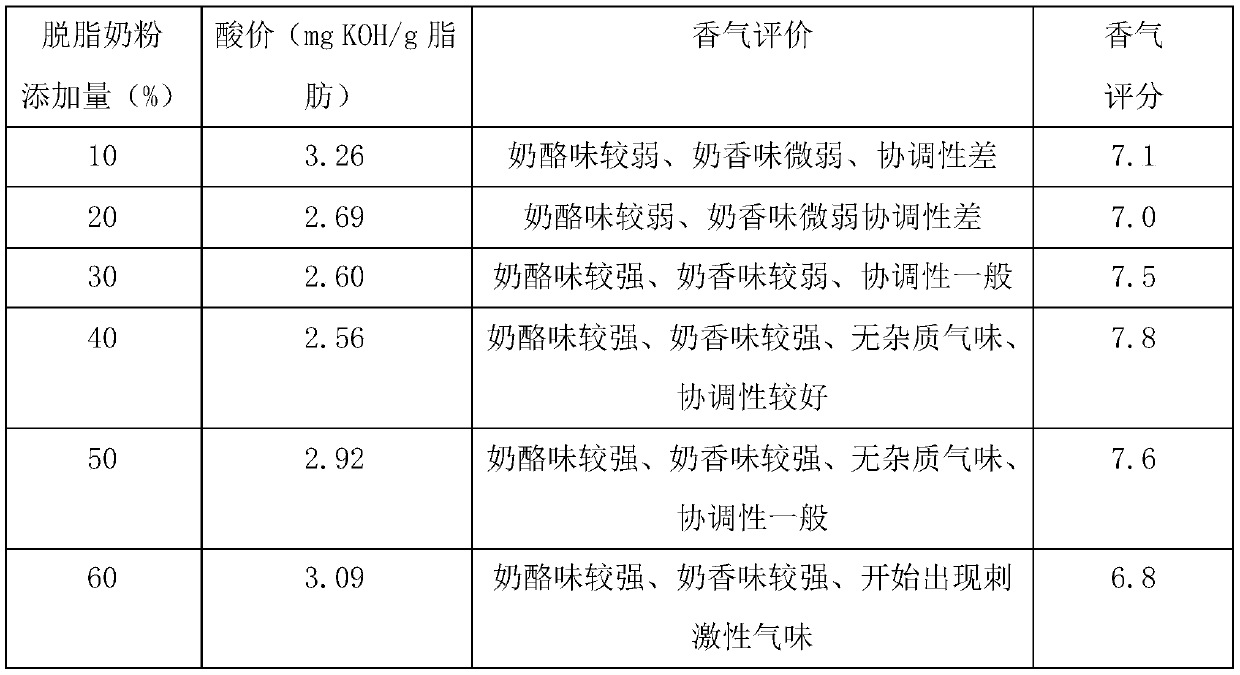

[0045] Skimmed milk powder: The mass ratio of skimmed milk powder to unsalted butter is 2:5;

[0046] Lipase MER: The mass ratio of lipase MER to unsalted butter is 21:100;

[0047] Protease AX: The mass ratio of protease AX to unsalted butter is 0.3:100;

[0048] Ethyl maltol: The mass ratio of ethyl maltol to unsalted butter is 0.75:100;

[0049] Vanillin: The mass ratio of vanillin to unsalted butter is 0.75:100;

[0050] A2. Take Duomei Fre...

Embodiment 2

[0055] For example, a natural milk flavor base prepared by a method for preparing a flavored natural milk flavor base, the natural milk flavor base is prepared as a mozzarella cheese flavor natural milk flavor base by the following raw material components: anhydrous cream, whey Powder, casein, ethyl maltol, lipase A12, protease MSD;

[0056] The specific steps include:

[0057] B1. Select the mass ratio of raw material components:

[0058] Anhydrous butter: based on 100 parts of anhydrous butter, anhydrous butter is preferred to Nestle anhydrous butter;

[0059] Whey powder and casein: whey powder and casein are mixed at a mass ratio of 4:1, and the mass ratio of mixed with anhydrous cream is 12.5:100;

[0060] Lipase A12: The mass ratio of lipase A12 to anhydrous cream is 0.75:100;

[0061] Protease MSD: The mass ratio of protease MSD to anhydrous cream is 0.03:100;

[0062] Ethyl maltol: The mass ratio of ethyl maltol to anhydrous cream is 0.75:100;

[0063] B2. Use Nestle anhydrous cre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com