Micro motor liquid pumping type electronic cigarette

A micro-motor and e-cigarette technology, applied in the field of e-cigarettes, can solve the problems of inability to quantitatively transport e-cigarettes, large volume of e-cigarettes, and low degree of integration, so as to avoid the discomfort of smoking and safety risks, low noise, and precise control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

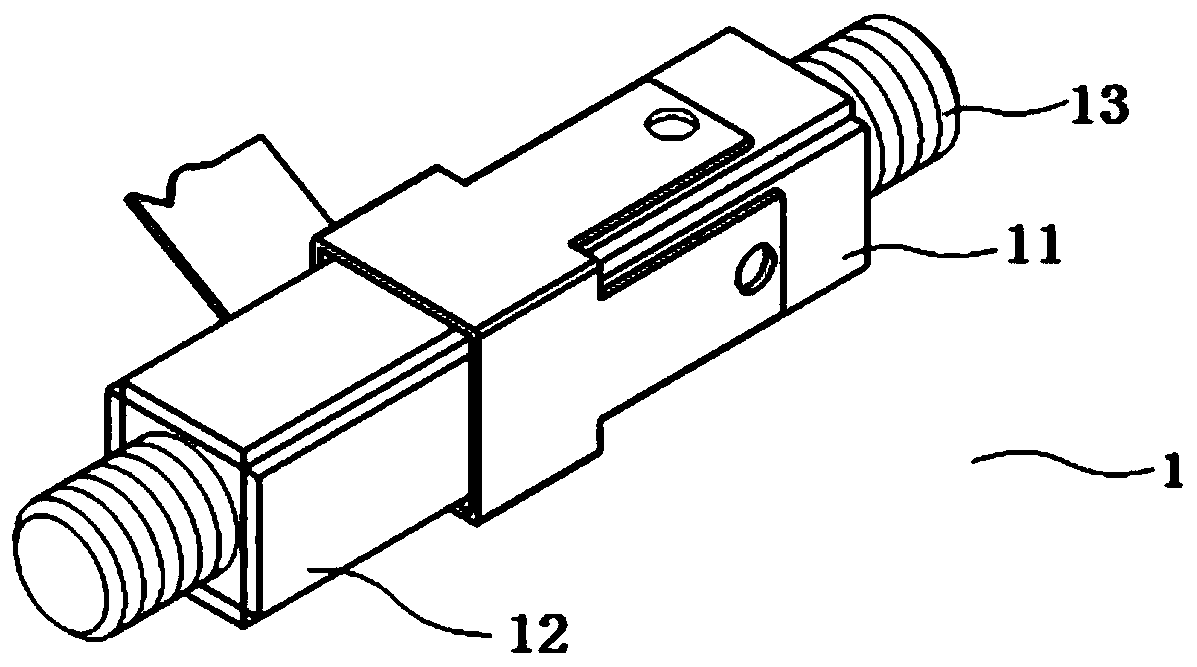

[0037] A micro-motor pump liquid electronic cigarette, comprising the following components:

[0038] A nebulizer 44, which includes a heating element 412;

[0039] The liquid storage bin 41, the liquid storage bin 41 is provided with an e-liquid extruding cylinder 49, and one end of the e-liquid extruding cylinder 49 is provided with an e-liquid injection pipe 411 in fluid communication with the heating element 412, and the e-liquid extruding cylinder 49 is away from The cylinder wall at one end of the heating element 412 is connected to the chamber wall of the liquid storage chamber 41 through the microvalve 410, and the smoke liquid extrusion cylinder 49 contains a piston 46 that can move along its inner wall;

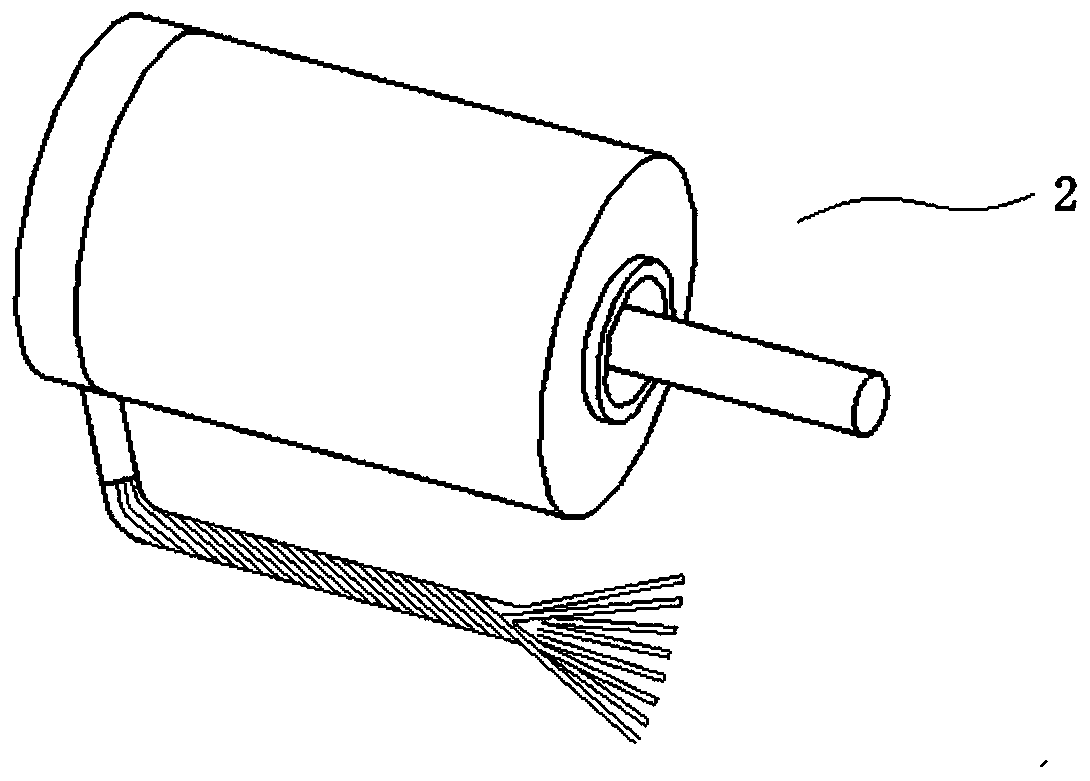

[0040] Micromotor 42, micromotor 42 is provided with micromotor driving rod 45, and micromotor driving rod 45 is fixedly connected with piston 46.

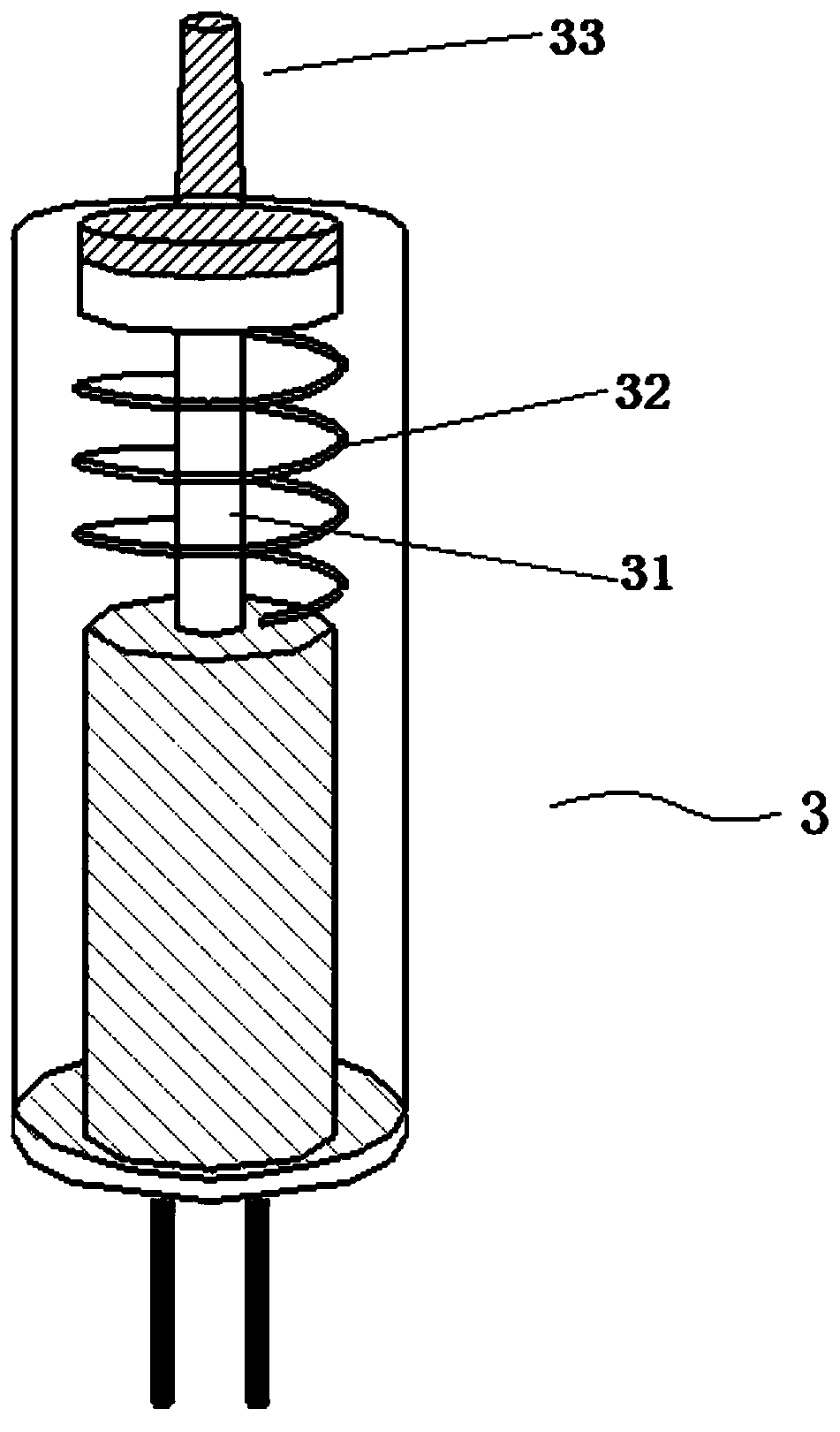

[0041] In this embodiment, the micromotor 42 is a shape memory alloy micromotor 3 .

[0042]The working principle of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com