Composite board for automobile interior decoration and preparation method thereof

A composite board and automobile technology, applied in the field of composite material production and thermoplastic resin composite material production, it can solve the problems of higher requirements for fabric covering, uneven surface layer, increased use cost, etc., to achieve excellent mechanical properties, smooth surface, The effect of good load-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

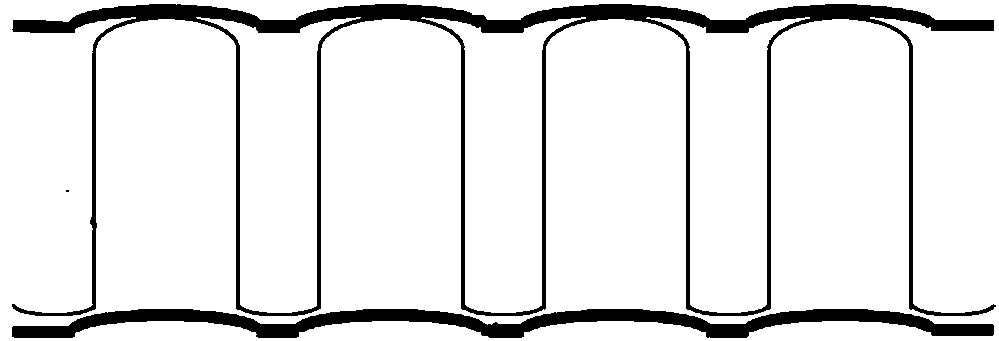

Image

Examples

Embodiment 1

[0038] The composite panel for automobile interior decoration of this embodiment is manufactured according to the above-mentioned preparation method, wherein the base material is selected as PP, the filler is talcum powder with 20% of the weight of the base material, and no high-temperature resistant additive is used;

[0039] Adjust the parameters so that K=0.5mm, D=0.4mm, L=4mm, H=8mm, and make composite board A, the thickness of the composite board is 9mm, and the surface density is 2000g / m 2 .

[0040] The commercially available thickness of the same weight is 9mm, and the surface density is 2000g / m 2 The discontinuous circular tube honeycomb panel D.

[0041] The composite panel A1 outside the range of the same structural parameters (K=0.5mm, D=0.15mm, L=3mm, H=8mm) was tested for comparison.

[0042] Under the condition of 23°C, the bending test was carried out according to GBT 1456-2005, and the measured load-bearing capacity of A was 191N, while the non-continuous ci...

Embodiment 2

[0046] The composite panel for automobile interior decoration of this embodiment is manufactured according to the above-mentioned preparation method, wherein the base material is selected as PP, the filler is talcum powder with 20% of the weight of the base material, and high-temperature-resistant additives accounting for 30% of the total weight of the raw materials are used: phosphorus-containing The mass ratio of epoxy resin, benzoxazine resin, dicyandiamide and silicon aluminate is 12:35:3:3.

[0047] Adjust and prepare the mold so that K=0.5mm, D=0.4mm, L=4mm, H=8mm, make composite board B, the thickness of the composite board is 9mm, and the surface density is 2000g / m 2 . A comparative test was carried out with the composite board B1 of the high-temperature-resistant additive with the same gram weight and the addition ratio (5:5:1:1). Tested under the GBT 1456-2005 sandwich structure bending performance test standard, the bending bearing capacity of the B composite plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com