Direct blowing type coal pulverizing system and method taking flue gas as drying medium

A technology of drying medium and pulverizing system, which is applied in the combustion method, drying gas arrangement, drying and other directions, can solve the problem of large fluctuation, affecting the coal purchasing economy of power plants, fuel supply safety, and insufficient drying output of pulverizing system. and other issues to achieve the effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

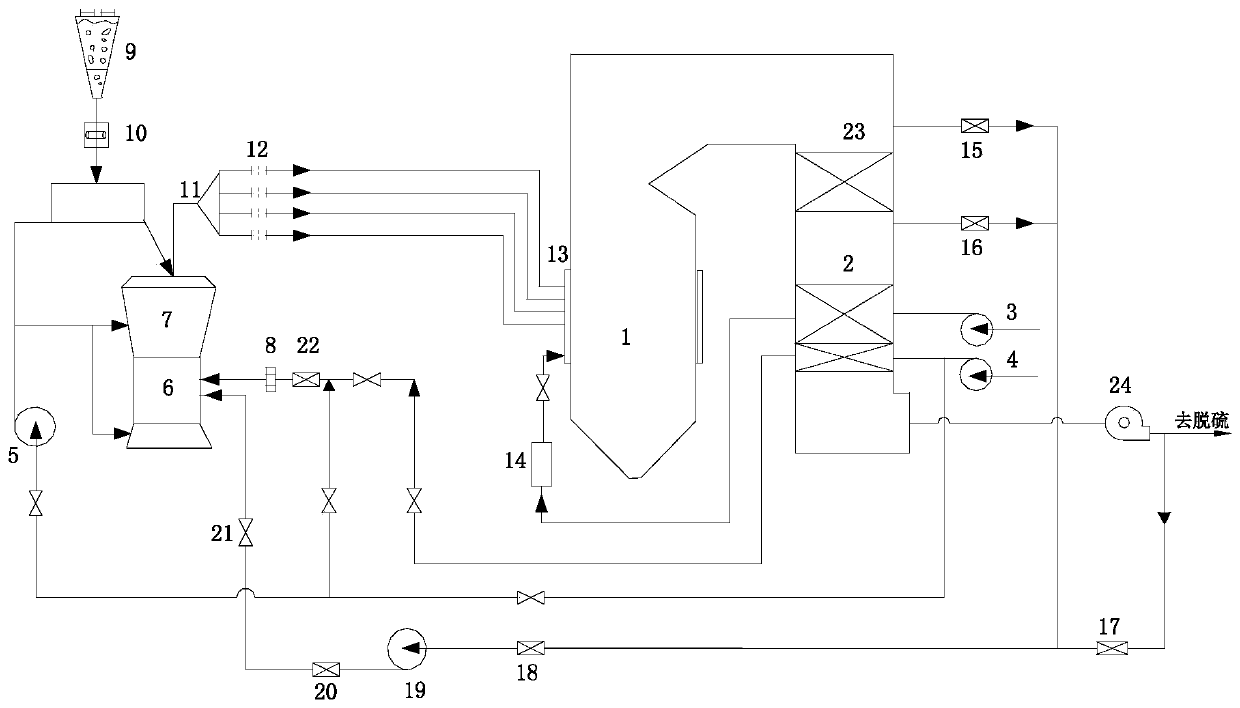

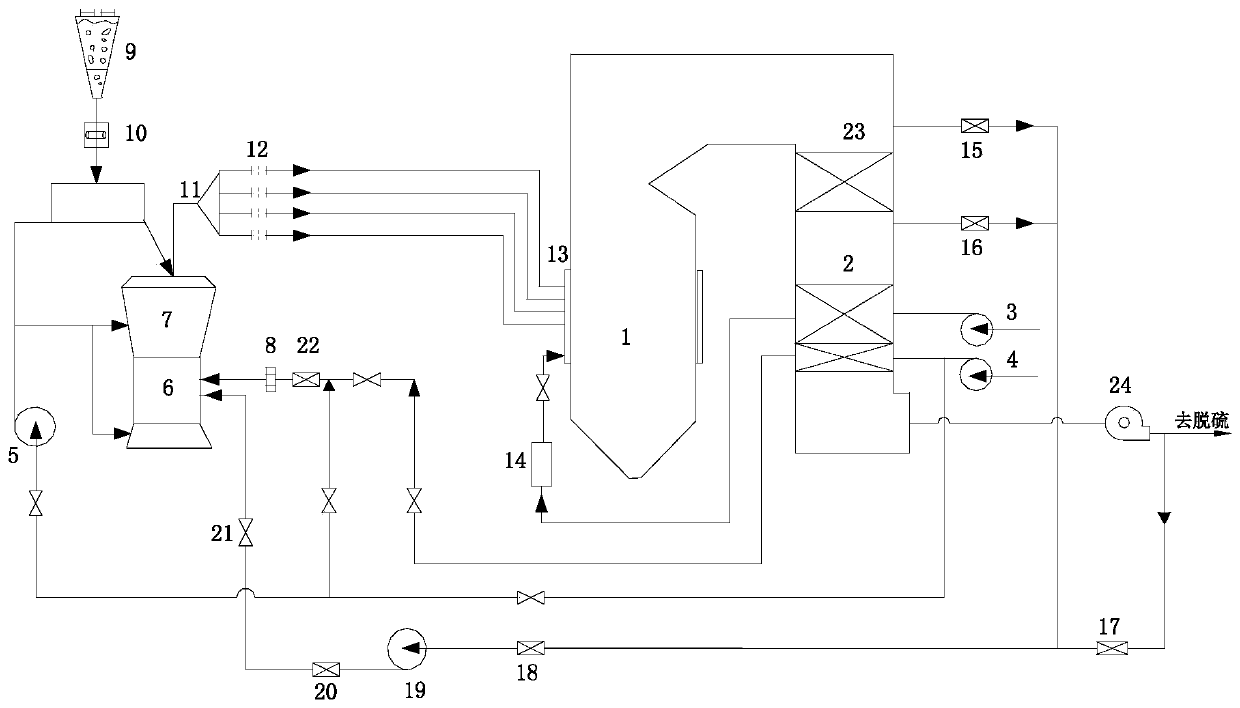

[0029] see figure 1 , a direct-blowing pulverizing system using furnace smoke as drying medium in the present invention, including air preheater 2, blower fan 3, primary fan 4, sealing fan 5, coal mill 6, coarse powder separator 7, raw coal hopper 9. Coal feeder 10, pulverized coal distributor 11, isolation door 12, powder burner 13, secondary wind box 14, high temperature furnace smoke regulating door 15, medium temperature furnace smoke regulating door 16, low temperature furnace smoke regulating door 17, mixing regulation Door 18, furnace smoke fan 19, furnace smoke fan outlet adjustment door 20, furnace smoke fan outlet cut-off door 21, hot air adjustment door 22, economizer 23, induced draft fan 24.

[0030] Wherein, the raw coal hopper 9 is used to supply coal for the coal feeder 10, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com