Centralized cold source refrigeration circulation system

A circulation system and centralized technology, applied in refrigerators, air-conditioning systems, refrigeration components, etc., can solve the problems of low utilization efficiency, high power consumption, and high inlet air temperature of the condenser, so as to avoid the heat island effect and improve the annual Energy efficiency ratio, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

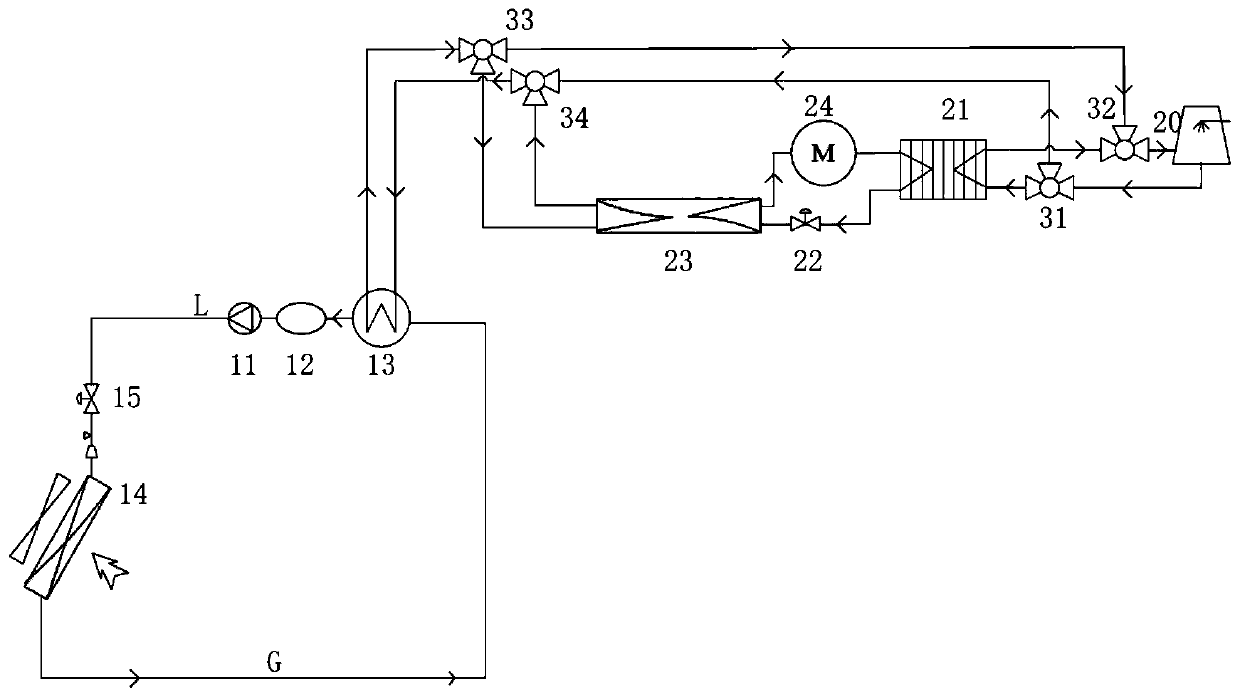

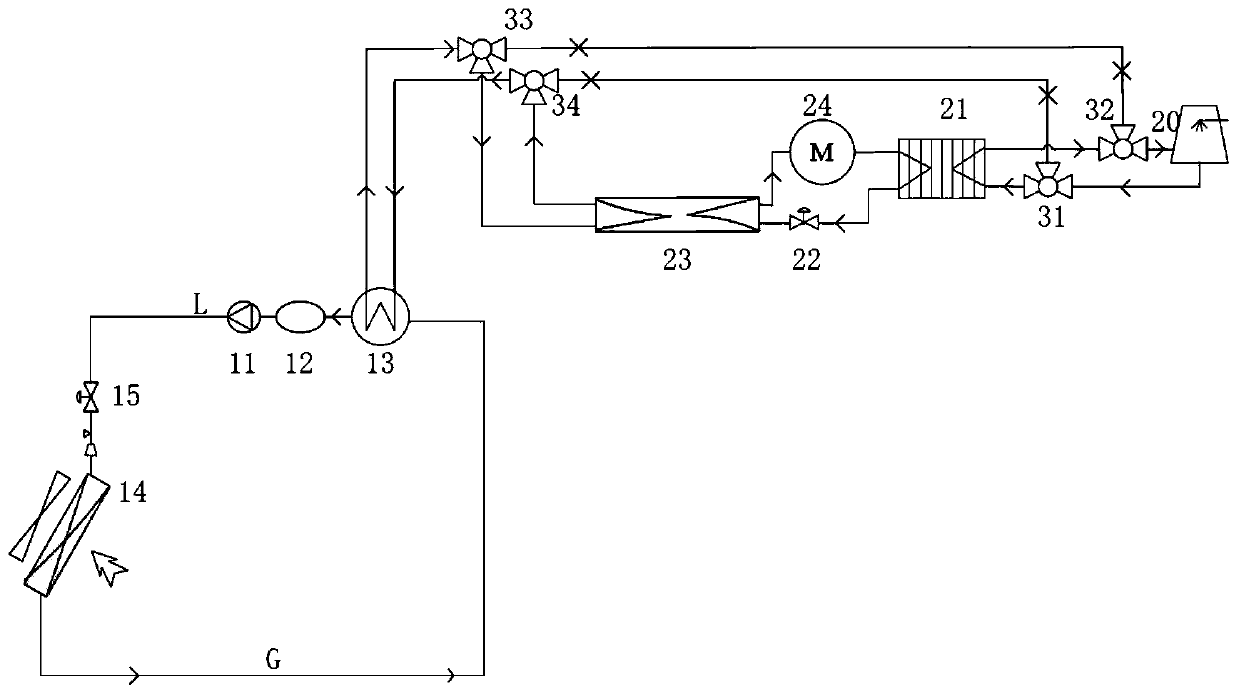

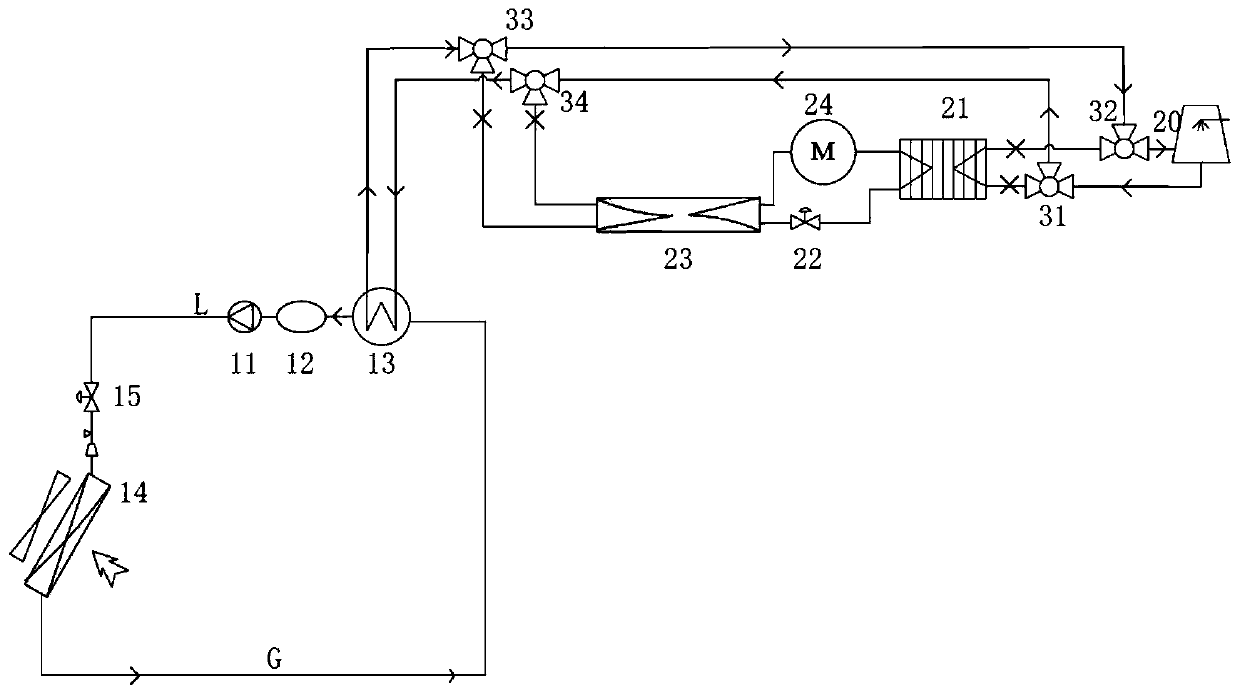

[0019] like figure 1 As shown, a centralized cold source refrigeration cycle system disclosed in the embodiment of the present invention is mainly composed of a direct refrigeration unit and a centralized cold source unit. The main components of the direct refrigeration unit include refrigerant pump 11, liquid receiver 12, water-cooled condenser A 13, evaporator 14, and throttling element A 15, and the main components of the centralized cold source unit include cooling tower 20 and water-cooled heat exchanger B 21. Throttling element B 22, water-fluorine heat exchanger 23, high-efficiency inverter compressor 24, and three-way valve I / II / III / IV (31 / 32 / 33 / 34). In the direct refrigeration unit, the refrigerant pump 11, the liquid receiver 12, the water-cooled condenser A 13, the evaporator 14, and the throttling element A15 are connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com