An explosive foil integrated chip based on low temperature co-fired ceramics and its preparation process

A technology of low-temperature co-fired ceramics and integrated chips, which is applied in blasting barrels, offensive equipment, weapon accessories, etc., can solve the problems of low energy utilization efficiency of explosive foil detonator units, difficulty in miniaturization, and unreliable functions, and achieve energy utilization The effect of increasing the efficiency, improving the consistency of the product, and reducing the ignition energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

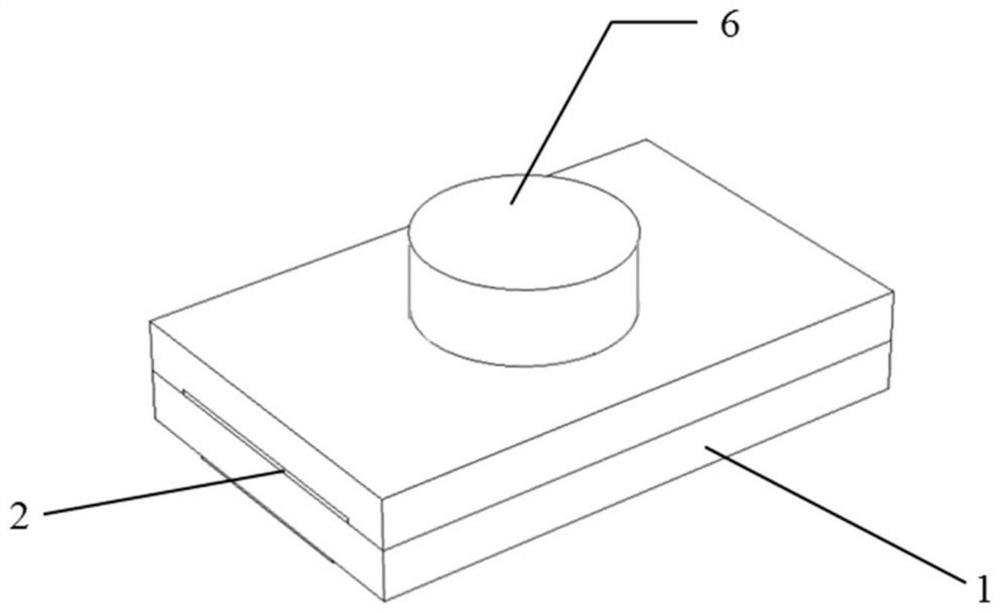

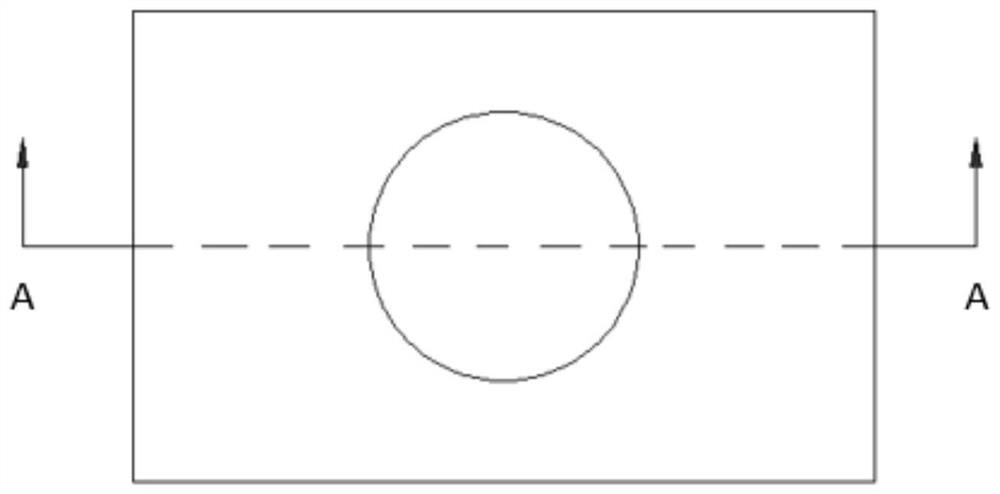

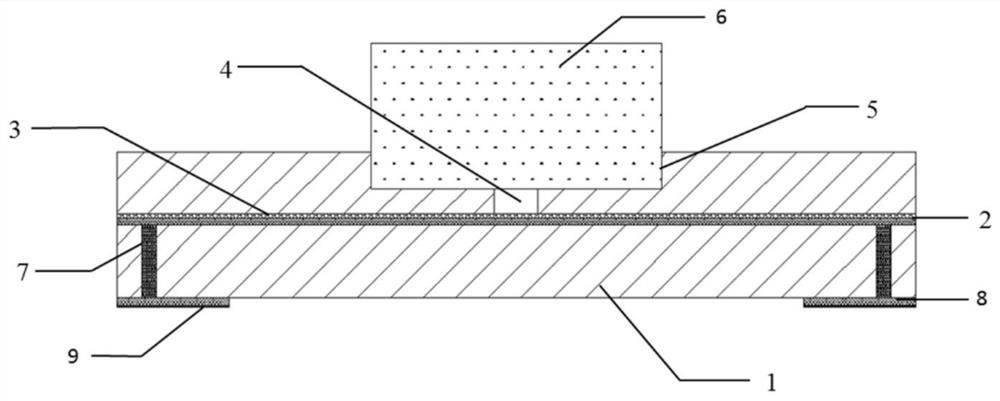

[0047] In this embodiment, an explosive foil detonator is designed on the basis of the explosive foil integrated chip unit, combining figure 1 to Figure 5 , the explosive foil integrated chip unit includes a ceramic substrate 1, a metal Au layer 2, a Parylene C layer 3-a, a metal W-Ti / Cu layer 3-b, an acceleration chamber 4, a charge tank 5 and an explosive column 6, In addition, it also includes metal via holes 7-a in the ceramic substrate 1, paste 7-b, pad area 8 on the back and Pd / Ag layer 9, etc. to facilitate connection with other parts. The ceramic substrate 1 is used as the back plate in the explosive foil integrated chip, and its length, width and height are 11mm×7mm×1mm respectively. The metal Au layer 2 is placed on the ceramic substrate 1 with a thickness of 6-10 μm. The metal Au layer 2 includes bridge Area 2-a, transition area 2-b, and conduction band 2-c. The bridge area 2-a is the part with the smallest cross-sectional area in the metal Au layer 2, and its ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com