Cathode electron enhancement device

A technology for boosting device and cathode electron emission, which is applied in the direction of electron multiplier dynode, electron multiplier details, dynode, etc. It can solve the problems of reduced service life of thermionic emission source, large heating wire current, etc., and achieve the realization of cathode Electron emission current, to achieve the effect of focusing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific examples.

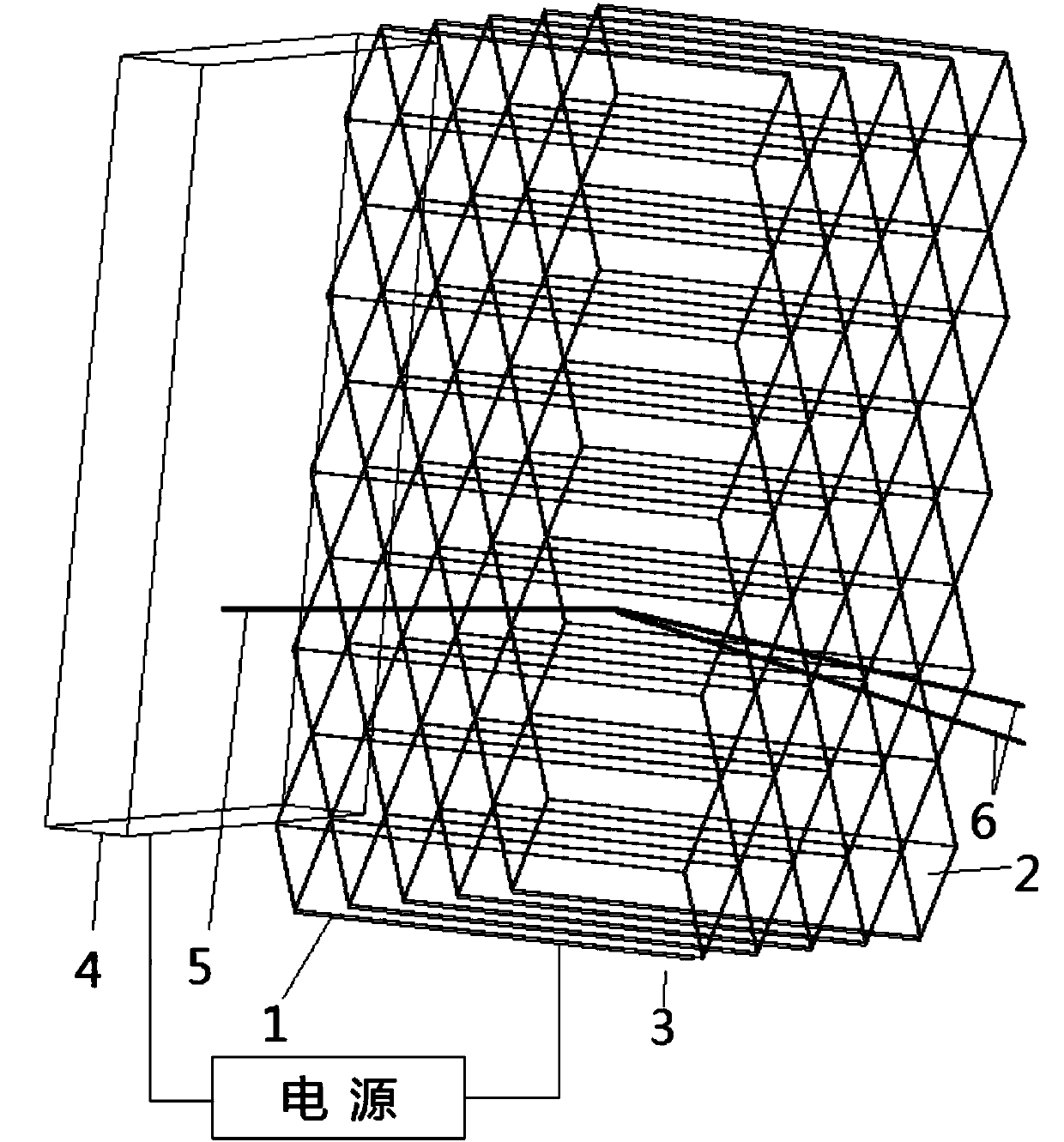

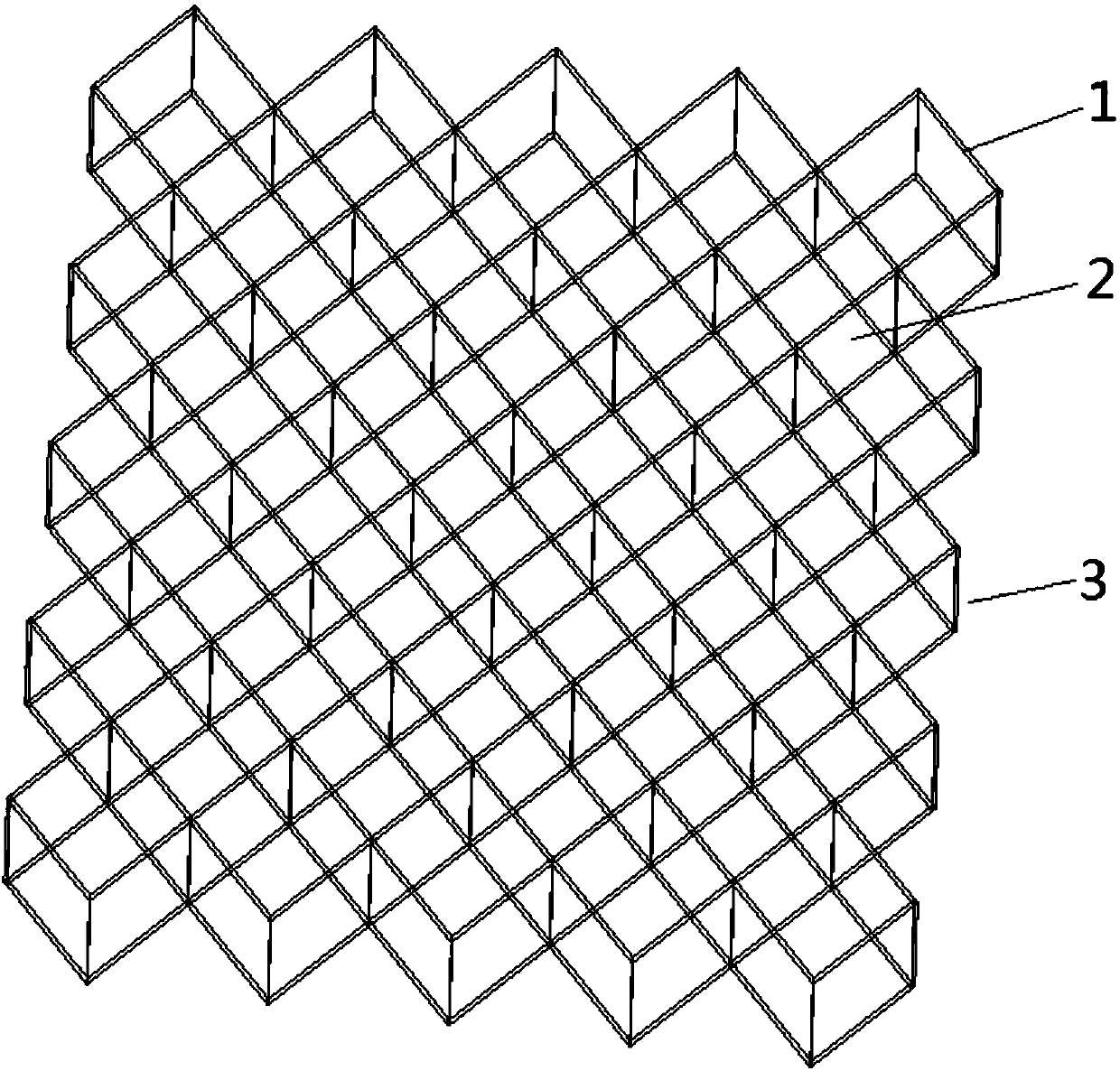

[0016] Such as figure 1 As shown, a cathode electron enhancement device of the present invention is composed of a high-voltage power supply, a cathode electron emission source (4) and a zigzag elongated metal sheet (1) with a certain width and length and a certain angle in section The sheet metal group (3) constitutes.

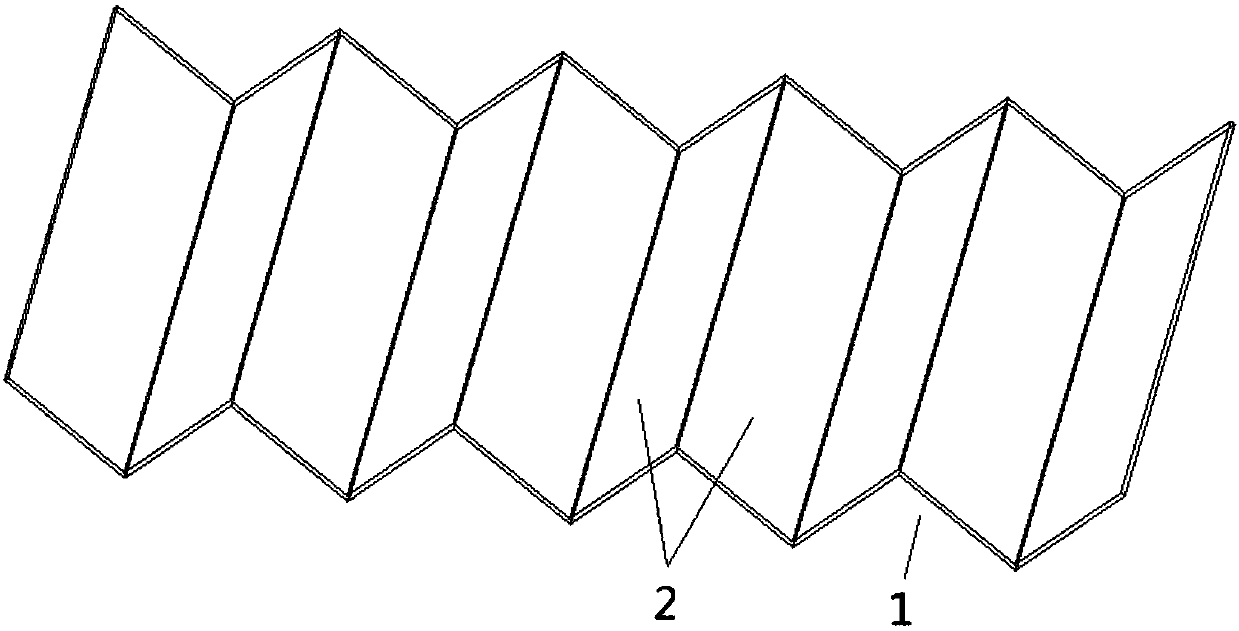

[0017] Such as figure 2 As shown, the metal thin plate (1) is an elongated thin plate with a certain thickness and a certain width, and a zigzag cross-section. The material is sputtered metal such as molybdenum or tungsten.

[0018] In order to increase the secondary electron emission coefficient of the surface (2) of the thin metal plate (1), the plasma injection or coating method is applied to the thin metal plate (1), and it is injected or coated within a certain depth on the surface (2) of the thin metal plate (1). Chemic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com