Method and fluid pump for conveying fluid in a fluid circuit of a motor vehicle

A fluid circuit, fluid pump technology, applied in the direction of fluid parameters, machines/engines, pumps, etc., can solve problems such as lack of regulation, affecting the efficiency of fluid pumps or motor vehicle transmissions, and inability to ensure efficient fluid delivery, achieving favorable determination, less cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

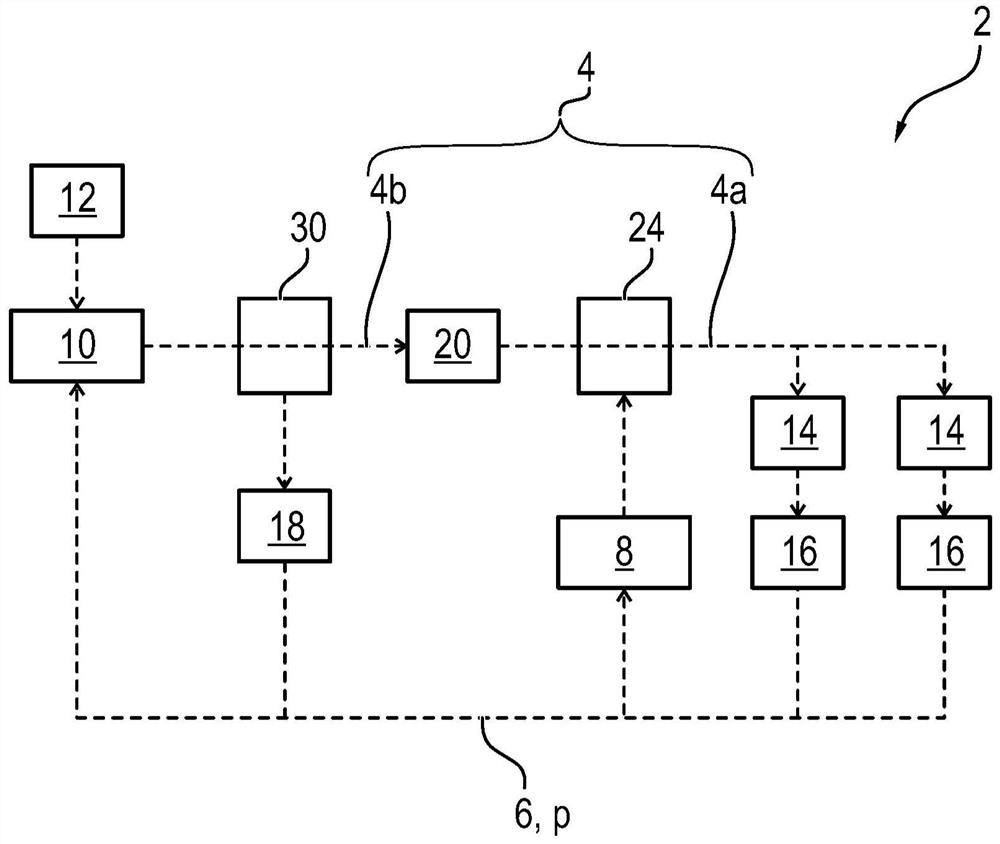

[0042] figure 1 The hydraulic system 2 shown in is suitable and set up for operating and lubricating a motor vehicle transmission, in particular a shift transmission, of a motor vehicle (not shown). To this end, the hydraulic system 2 comprises a fluid or oil circuit 4 shown in dashed lines for conducting (hydraulic) fluid 6 , in particular (transmission) oil. The hydraulic system 2 has two fluid or oil pumps 8 and 10 for conveying the oil 6 in the oil circuit 4 . The oil pump 8 is designed here as a main pump, while the oil pump 10 is designed as an auxiliary or supplementary pump of the oil circuit 4 .

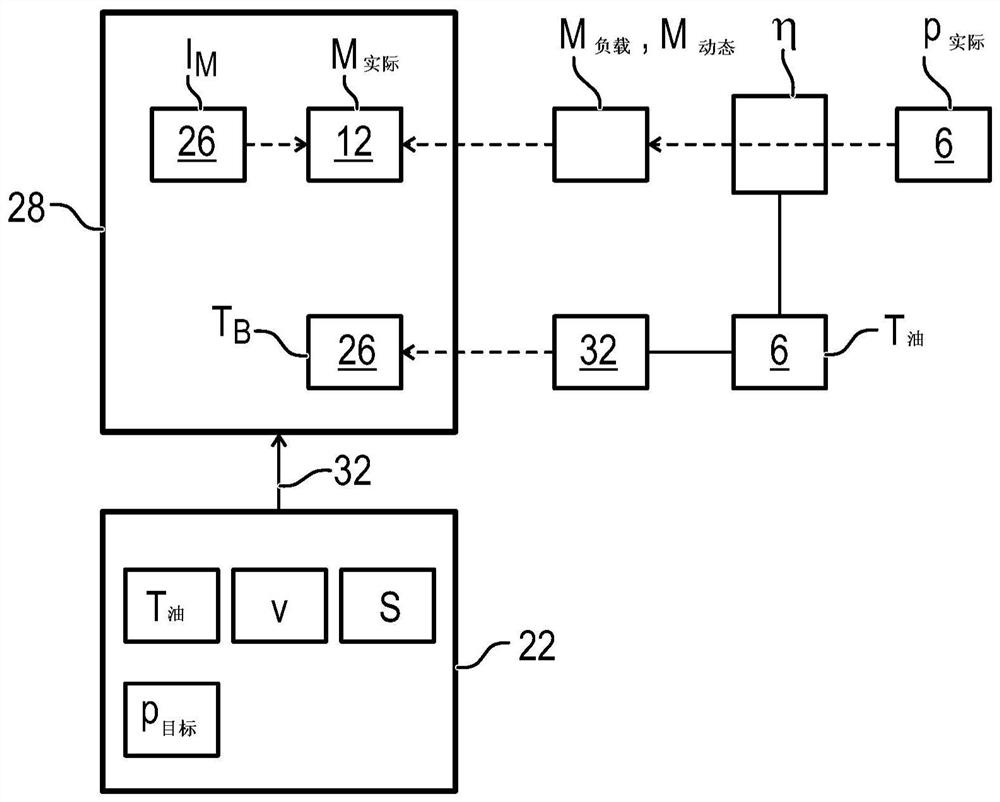

[0043] In this case, the oil pump 8 is coupled to the internal combustion engine of the motor vehicle and can be functionally driven by the internal combustion engine for conveying the oil 6 . The oil pump 10 is implemented electrically and has a driven electric motor 12 . The electric motor 12 is designed, for example, as a brushless DC motor and has a rotatably mounted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com