Multifunctional combined rice mill

A multi-functional combination, rice milling machine technology, applied in the direction of grain degerming, grain processing, grain pod removal, etc., can solve the problems of high rice residue rate, low production efficiency, large production noise, etc., to shorten the process flow, occupy The effect of small space and simple structure principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention is further described below in conjunction with specific embodiment:

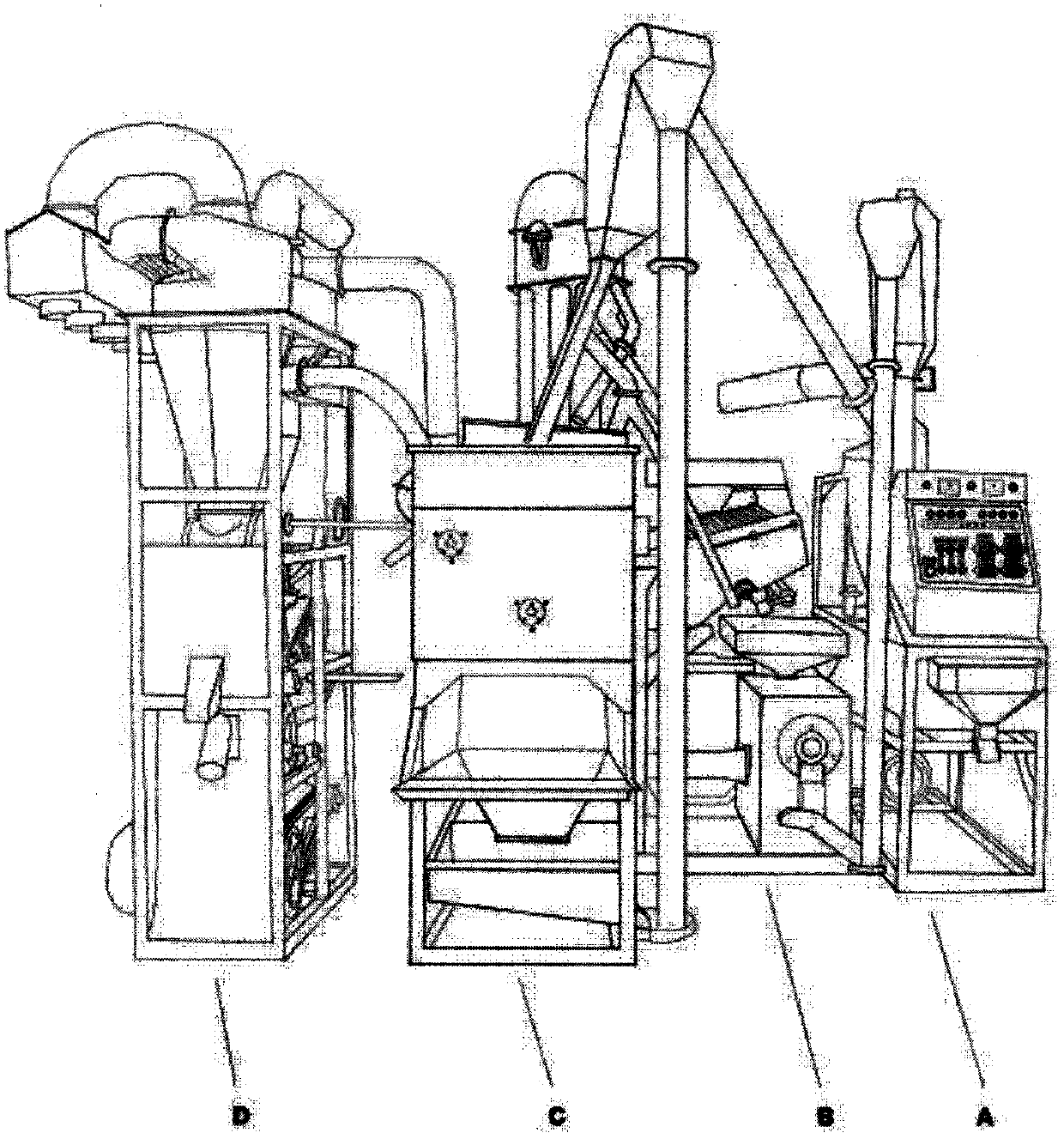

[0046] Such as figure 1 As shown, the multifunctional combined rice milling machine of the present invention includes the following four parts: Part A is an electric control and fan part, part B is a gravity sieve and a rice mill part, and part C is a destoner and a hoist part, Part D is the part of the mixed bran crushing device.

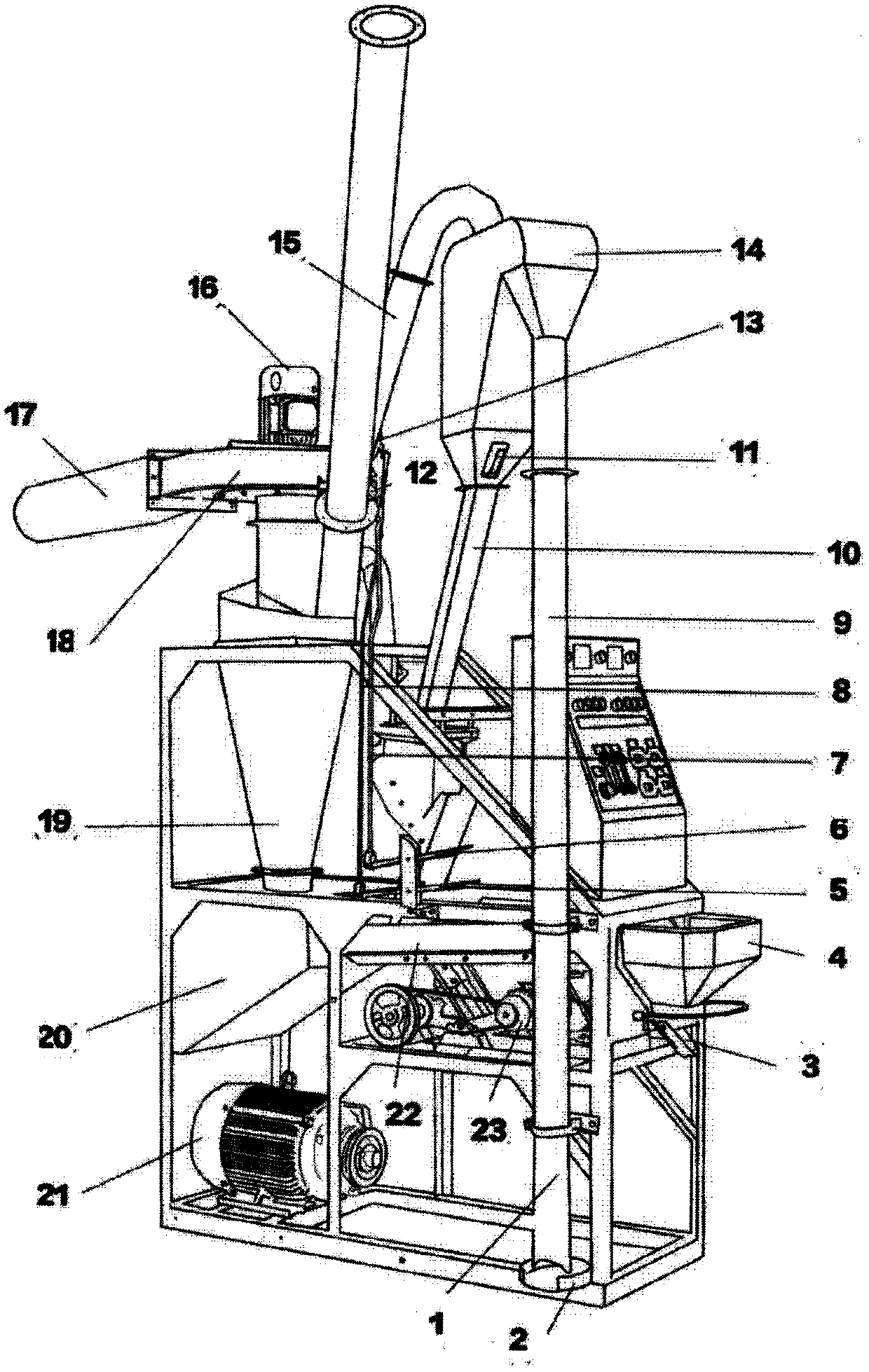

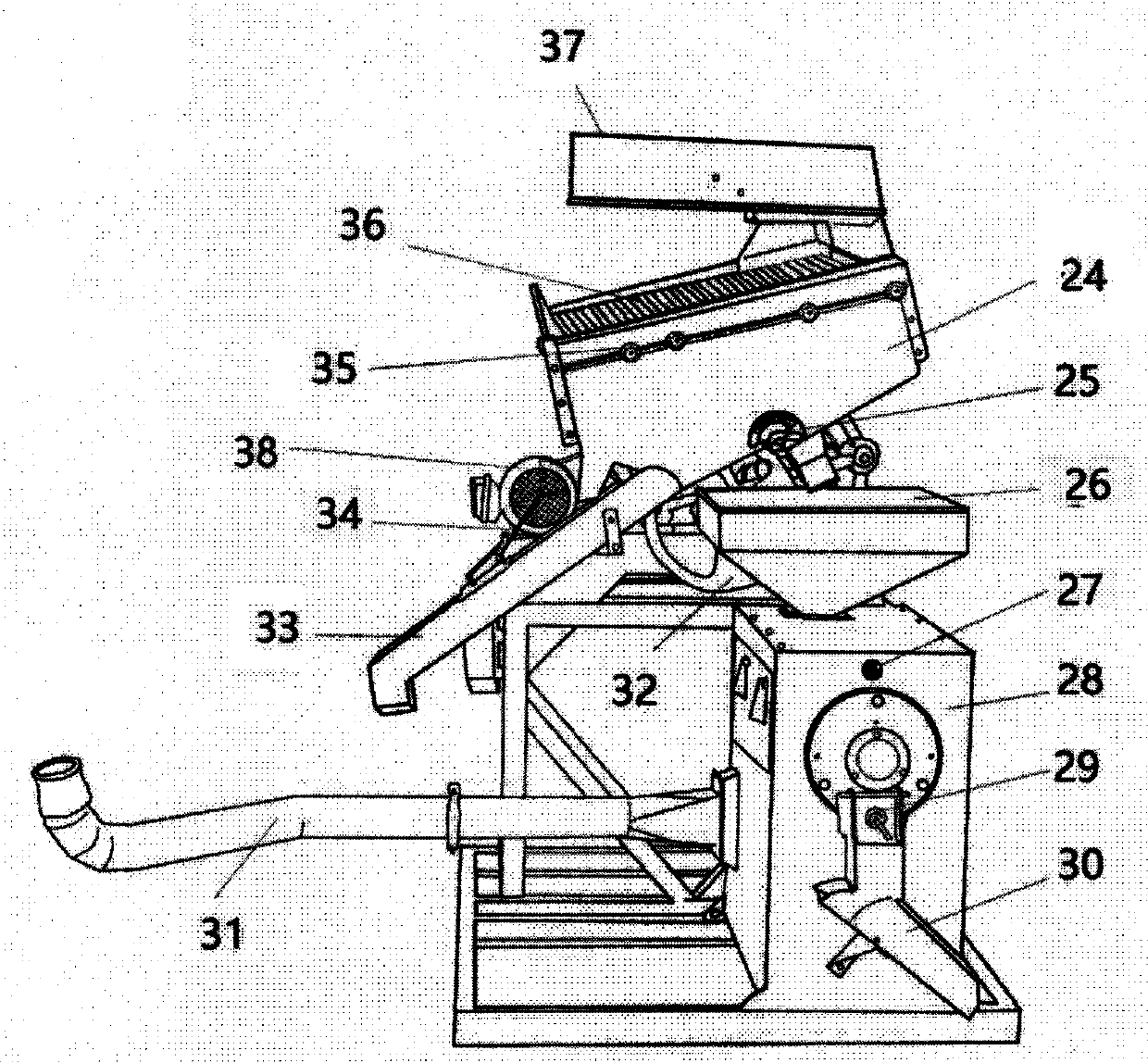

[0047] Such as Figure 2 to Figure 6As shown, the device of the electric control and fan part of the multifunctional combined rice milling machine of the present invention includes a rice whitening tube sleeve 1, a rice whitening plate 2, a white rice unloading port 3, a rice whitening bucket 4, a grain pipe damper joystick 5, Rice pipe damper joystick 6, rice damper line 7, valley damper line 8, white rice air duct 9, rice discharge pipe 10, rice observation window 11, valley pipe damper 12, rice pipe damper 13, rice unloader 14, rice Air duct 15,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com