Manufacturing method of high-temperature alloy forge piece for nuclear power steam generator

A technology of steam generator and high-temperature alloy, which is applied in the field of forging manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

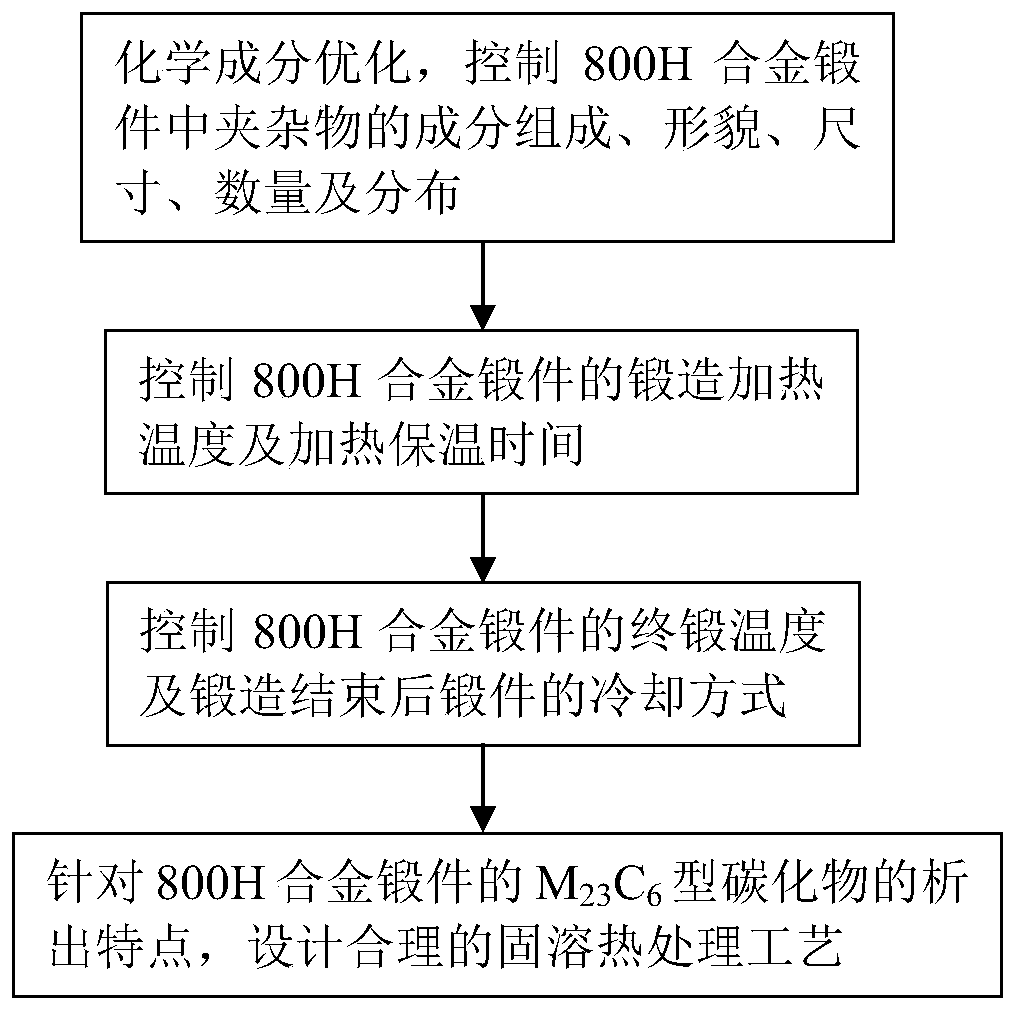

Method used

Image

Examples

Embodiment 2

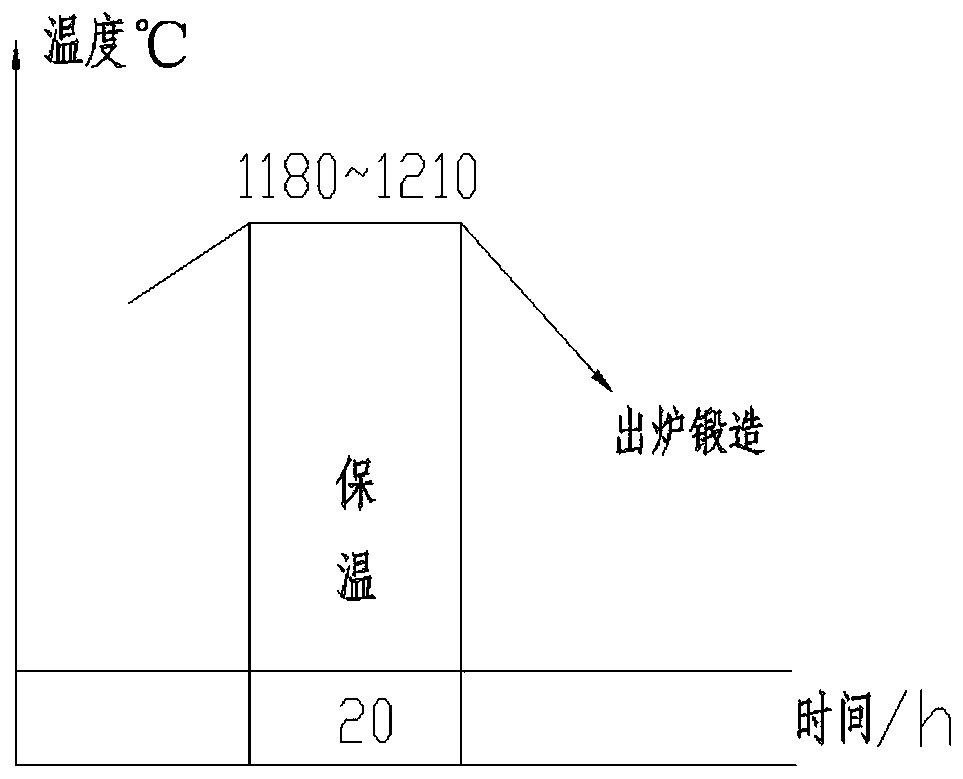

[0045] Such as figure 1 As shown, on the basis of Example 1, the forging heating temperature and heating and holding time of the 800H alloy forging are controlled.

[0046] It has been observed that the harmful inclusions in the 800H alloy begin to nucleate and grow during the solidification of the molten steel, and the inclusions will grow further after the molten steel solidifies. In addition, at about 1100 ° C, there will be M 23 C 6 Type carbides start to precipitate. For the case where the 800H alloy steel ingot used for the forging of the steam generator for the nuclear power high-temperature gas-cooled reactor has been cooled by passing cooling water through the steel ingot mold in the process of electroslag remelting, the cooling rate of the steel ingot is still limited due to the large size of the steel ingot. During the solidification and cooling process of molten steel, a certain degree of dendrite segregation will still be formed, the distribution of alloy elemen...

Embodiment 3

[0050] Such as figure 1 As shown, on the basis of Example 2, the final forging temperature of the 800H alloy forging and the cooling method of the forging after forging are controlled.

[0051] As mentioned earlier, 800H alloy forgings have M at around 1100°C 23 C 6 type carbide precipitation, in order to minimize the M 23 C 6 To prevent the precipitation of type carbides, the final forging temperature of the forging should be controlled above 1100°C as much as possible, and the forging should be water-cooled immediately after forging.

Embodiment 4

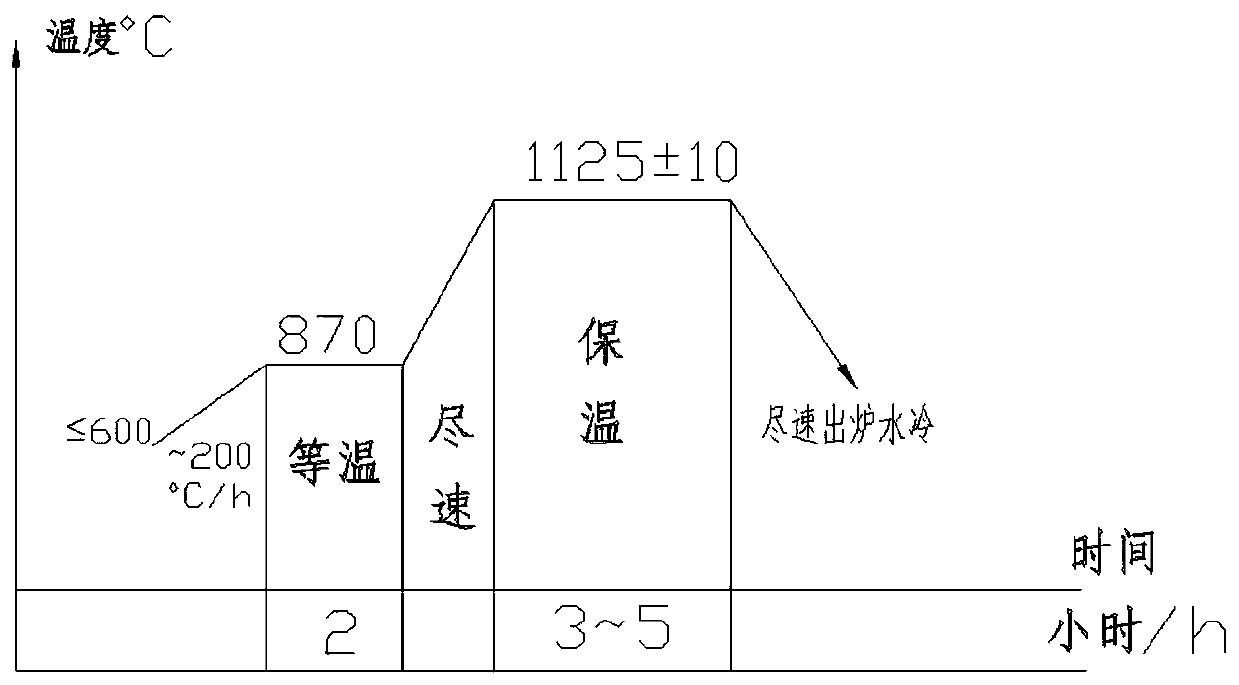

[0053] In the technology of embodiment three, for the M of 800H alloy forging 23 C 6 According to the precipitation characteristics of type carbides, a reasonable solution heat treatment process is designed.

[0054] For the 800H alloy used in the steam generator forgings of nuclear power high temperature gas-cooled reactors, the control of its high temperature mechanical properties largely depends on the selection of the heating rate of the forgings and the determination of the solid solution holding temperature and holding time of the forgings. Although the 800H alloy forging is water-cooled after forging, it is inevitable that there will be some M 23 C 6 Type carbides are precipitated in the alloy, especially for forgings with obvious main processing direction. According to its deformation characteristics, M 23 C 6 Type carbides are easy to precipitate in bands along the main processing direction of the forgings; in addition, if the 800H alloy forgings are heated at a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com