Sewage disposal tank integrating diversified processes of Orbal, bio-dopp, MBBR and MBR

A sewage treatment tank and biological multiplication technology, applied in biological water/sewage treatment, sustainable biological treatment, water/sludge/sewage treatment, etc., which can solve the problems of large area, poor effluent quality and low treatment capacity. , to achieve the effect of small footprint, low equipment operating costs and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

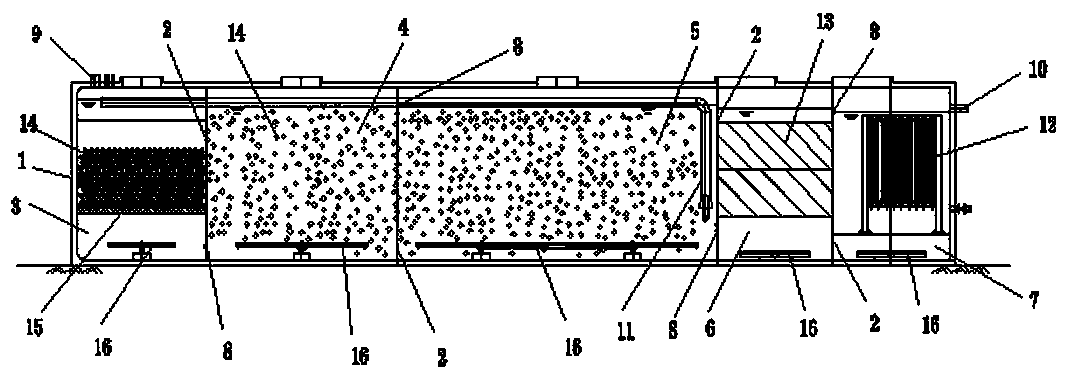

[0032] Embodiment 1: as figure 1 As shown, a sewage treatment tank integrating Aubauer, biological multiplication, MBBR, and MBR multiple technologies, including a tank body 1, the tank body 1 is a plate structure or a hollow ribbed structure, and the heads at both ends of the tank body 1 It is a flat head or an arc-shaped head. The tank body 1 is provided with a compartment plate 2 to divide the tank body 1 into anaerobic zone 3, anoxic zone 4, aerobic zone 5, sedimentation zone 6, and membrane filtration zone 7. The compartment plate 2 is provided with water holes 8. The tank body 1 is provided with a water inlet 9 and a water outlet 10, the water inlet 9 is located in the anaerobic zone 3, the water outlet 10 is located in the membrane filtration zone 7, the volume of the anaerobic zone 3, the anoxic zone 4, and the aerobic zone 5 The ratio is 18~25:25~35:45~60, the aerobic zone 5 returns to the anaerobic zone 3 through the sludge return pipeline 11; the end of the sludge ...

Embodiment 2

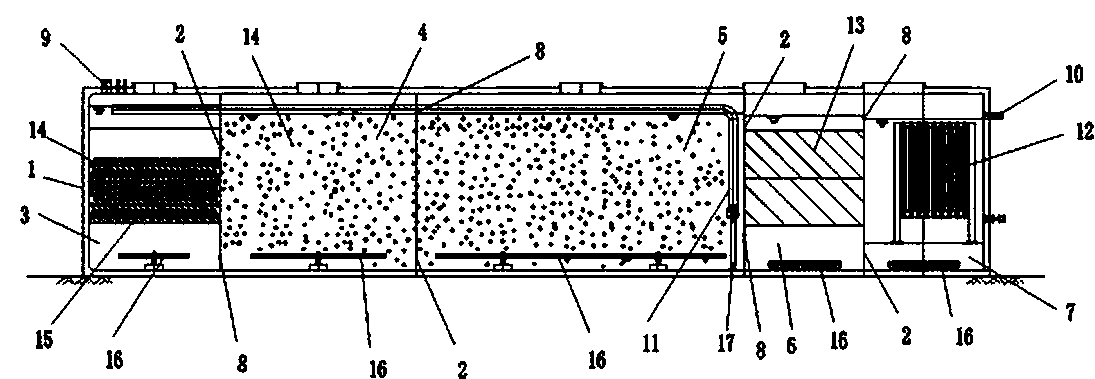

[0033] Embodiment 2: as figure 2 As shown, a sewage treatment tank integrating Aubauer, biological multiplication, MBBR, and MBR multiple technologies, including a tank body 1, the tank body 1 is a plate structure or a hollow ribbed structure, and the heads at both ends of the tank body 1 It is a flat head or an arc-shaped head. The tank body 1 is provided with a compartment plate 2 to divide the tank body 1 into anaerobic zone 3, anoxic zone 4, aerobic zone 5, sedimentation zone 6, and membrane filtration zone 7. The compartment plate 2 is provided with water holes 8. The tank body 1 is provided with a water inlet 9 and a water outlet 10. The water inlet 9 is located in the anaerobic area 3, the water outlet 10 is located in the membrane filtration area 7, the anaerobic area 3, the anoxic area 4, the aerobic area 5, and the sedimentation area. The volume ratio of zone 6 and membrane filtration zone 7 is 18~25:25~35:45~60:15~25:15~25; aerobic zone 5 returns to anaerobic zone...

Embodiment 3

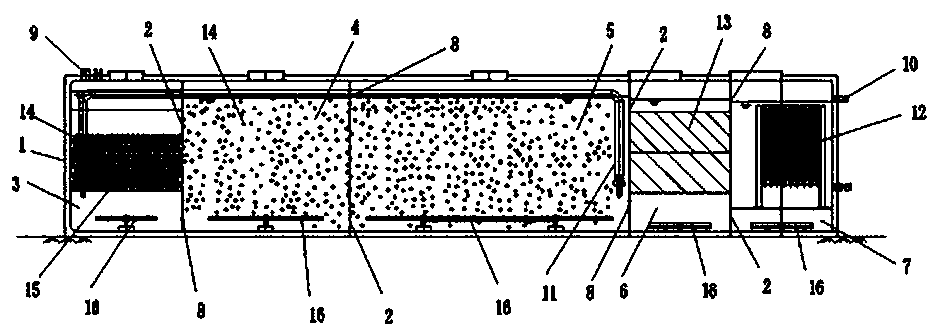

[0034] Embodiment 3: as image 3 As shown, a sewage treatment tank integrating Aubauer, biological multiplication, MBBR, and MBR multiple technologies, including a tank body 1, the tank body 1 is a plate structure or a hollow ribbed structure, and the heads at both ends of the tank body 1 It is a flat head or an arc-shaped head. The tank body 1 is provided with a compartment plate 2 to divide the tank body 1 into anaerobic zone 3, anoxic zone 4, aerobic zone 5, sedimentation zone 6, and membrane filtration zone 7. The compartment plate 2 is provided with water holes 8. The tank body 1 is provided with a water inlet 9 and a water outlet 10, the water inlet 9 is located in the anaerobic zone 3, the water outlet 10 is located in the membrane filtration zone 7, the volume of the anaerobic zone 3, the anoxic zone 4, and the aerobic zone 5 The ratio is 18~25:25~35:45~60, the aerobic zone 5 returns to the anaerobic zone 3 through the sludge return pipeline 11; the sedimentation zone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com