High strength die thermal insulation board and preparation method thereof

A heat insulation board and high-strength technology, which is applied in the field of high-strength mold heat insulation board and its preparation, can solve the problems of low strength and poor heat insulation effect, and achieve good mechanical strength, enhanced heat insulation effect, and structural density uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

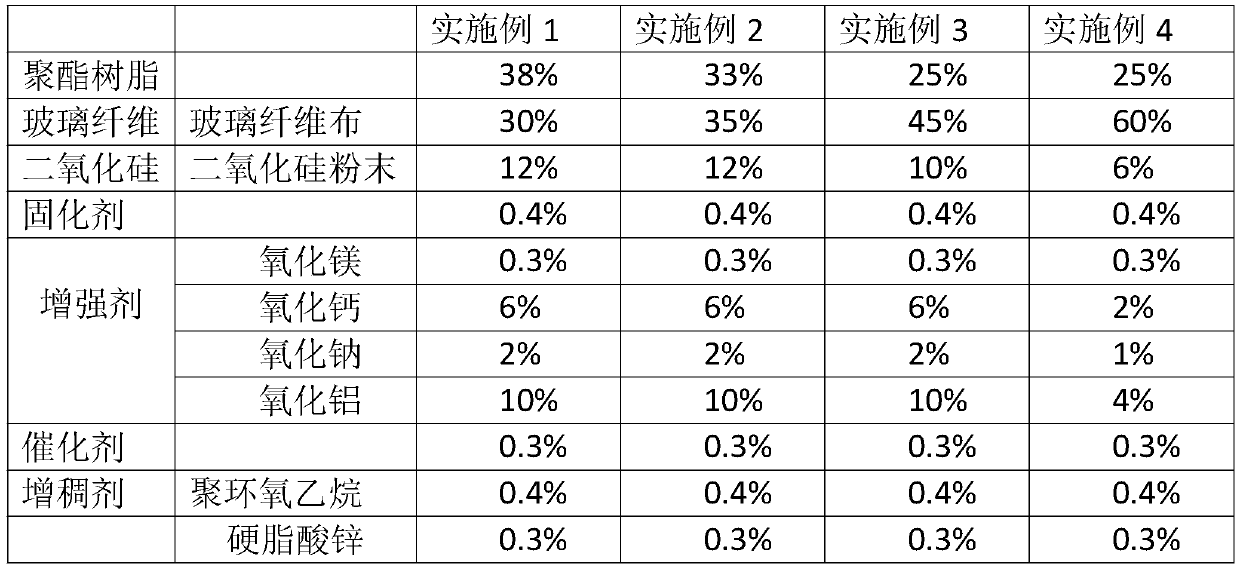

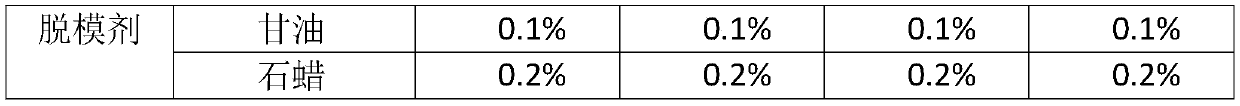

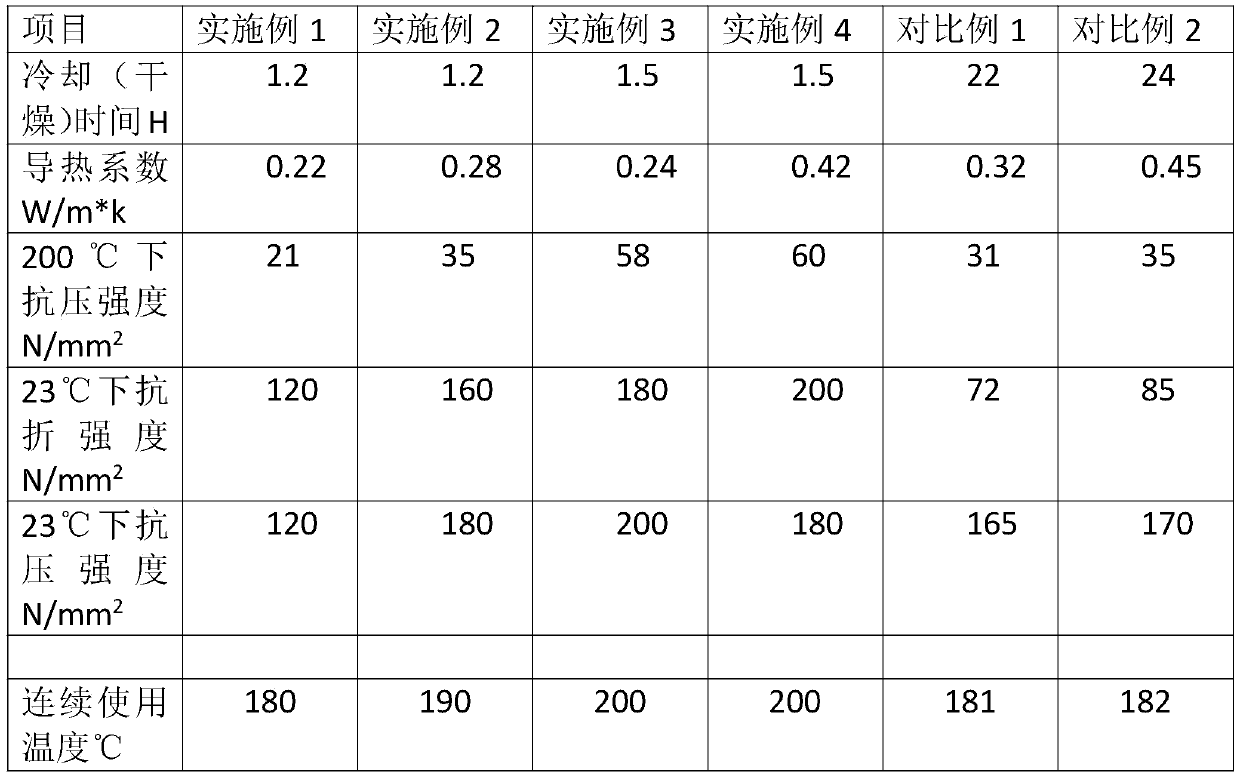

[0043] The present invention will be further described below in conjunction with specific embodiments.

[0044] A method for preparing a high-strength mold heat insulation board, comprising the steps of:

[0045] Step 1: Mixing materials, adding polyester resin and silica powder into the high-speed disperser, then adding curing agent, reinforcing agent and additives, and starting the machine to stir until the mixture is uniform to make a resin compound;

[0046] Step 2: Applying glue, mixing glass fiber cloth or glass fiber mat or glass fiber filament with the resin glue in step 1 in the glue applicator to make a prepreg;

[0047] Step 3: spread and pressurize, lay the prepreg in step 2 layer by layer in the press mold, pressurize and solidify under the conditions of pressure of 2000-3000 tons / square meter and temperature of 100-160°C;

[0048] Step 4: Demoulding, keeping the pressure in the press and forcing cooling for 1 to 1.5 hours, until it is cooled to 80°C and then dem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap