Inner wall putty and preparation method thereof

An interior wall putty, the technology of parts by weight, applied in the direction of filling slurry, etc., can solve the problems of endangering the health of residents, short action time, small dosage, etc., and achieves suitable for large-scale production and popularization and application, simple preparation process, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

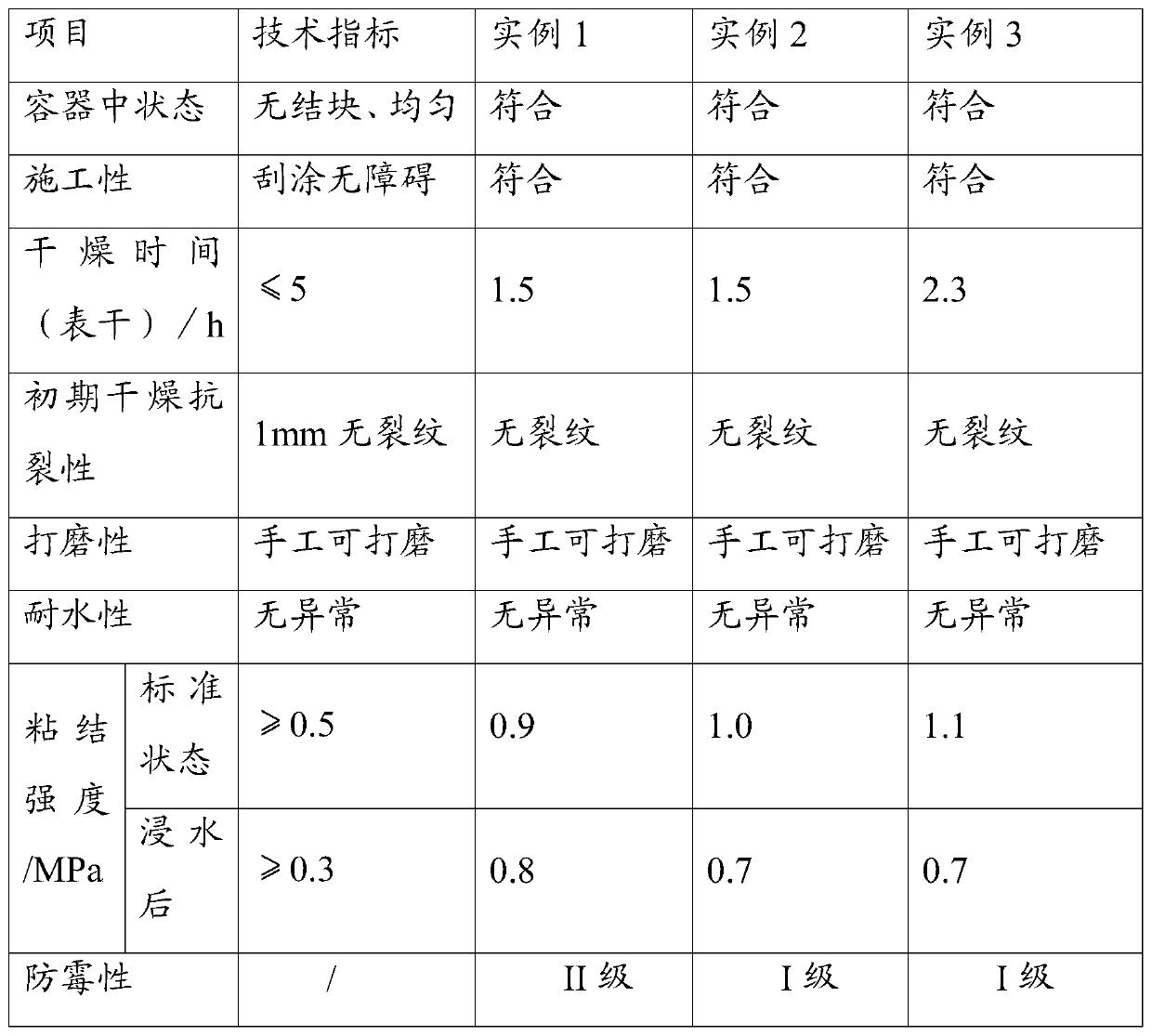

Examples

Embodiment Construction

[0020] The following clearly and completely describes the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

[0021] 1. Preparation of putty powder

[0022] The sources of raw materials used in the examples are as follows: ash calcium powder is selected from the 325-mesh model produced by Jingxing County New Century Calcium Industry Co., Ltd., talcum powder is selected from the 325-mesh model produced by Beijing Liguo Weiye Company, and hydroxypropyl methylcellulose is selected from Hebei Province. The HPMC80000 type produced by Zhicheng Cellulose Co., Ltd., the redispersible rubber powder is selected from the 5044N type produced by Wacker ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com