Multifunctional heat treatment device for crankshaft machining device

A heat treatment device and crankshaft processing technology, applied in heat treatment furnaces, heat treatment equipment, quenching devices, etc., can solve the problems of not having the ability to remove residues on the surface of the crankshaft to prevent pollution, unable to hoist different types of crankshafts, and inconvenient for cooling and storage of crankshafts, to ensure that the The effect of heat treatment, the addition of anti-pollution function, and the effect of meeting the needs of automatic processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

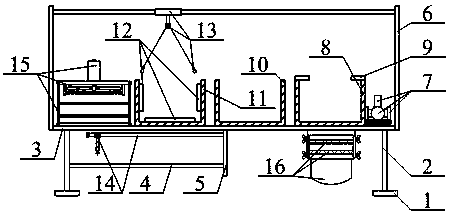

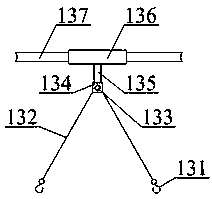

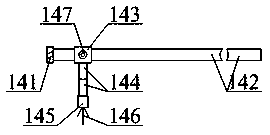

[0044] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, a multifunctional heat treatment device for crankshaft processing includes a support foot 1, a support leg 2, a base 3, a hollow plate 4, a support seat 5, a support column 6, a high-pressure water pump 7, a quenching chamber 8, and a fan 9 , an annealing chamber 10, a normalizing chamber 11, a heater 12, an automatic sliding adjustment crankshaft suspension hook structure 13, a slidable mobile crankshaft surface residue cleaner 14, an auxiliary cooling temporary storage rack 15 after crankshaft heat treatment and a waste liquid treatment collection tank after quenching Structure 16, the bolts at the middle positions of the supporting legs 1 are respectively mounted on the lower ends of the supporting legs 2; the longitudinal upper ends of the supporting legs 2 are bolted at the four corners of the bottom of the base 3 respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com