FeCrAl alloy and T91 ferrite/martensite heat-resistant steel composite tube for nuclear reactor nuclear fuel cladding and manufacturing method for FeCrAl alloy and T91 ferrite/martensite heat-resistant steel composite tube

A nuclear reactor and ferrite technology, applied in heat treatment equipment, heat treatment furnaces, manufacturing tools, etc., can solve problems such as uneven thickness of the inner and outer layers, poor quality of the inner surface of the tube billet, etc., to improve the ability of anti-radiation, The effect of improving the ability to resist LOCA accidents and improving the ability to resist high-temperature oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

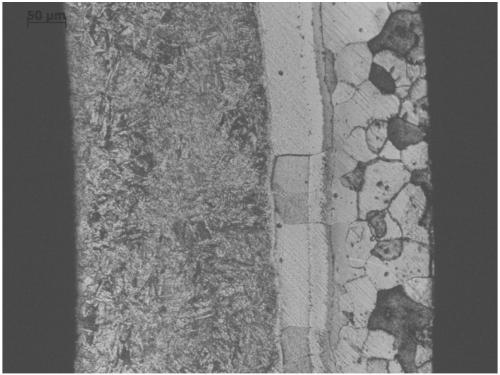

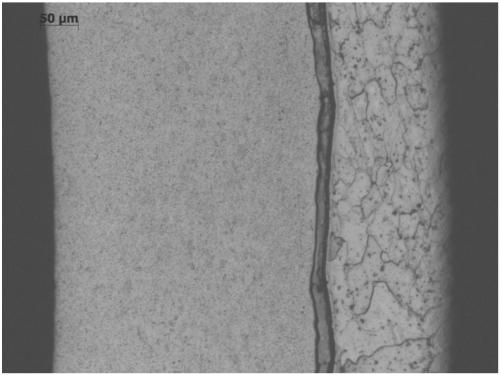

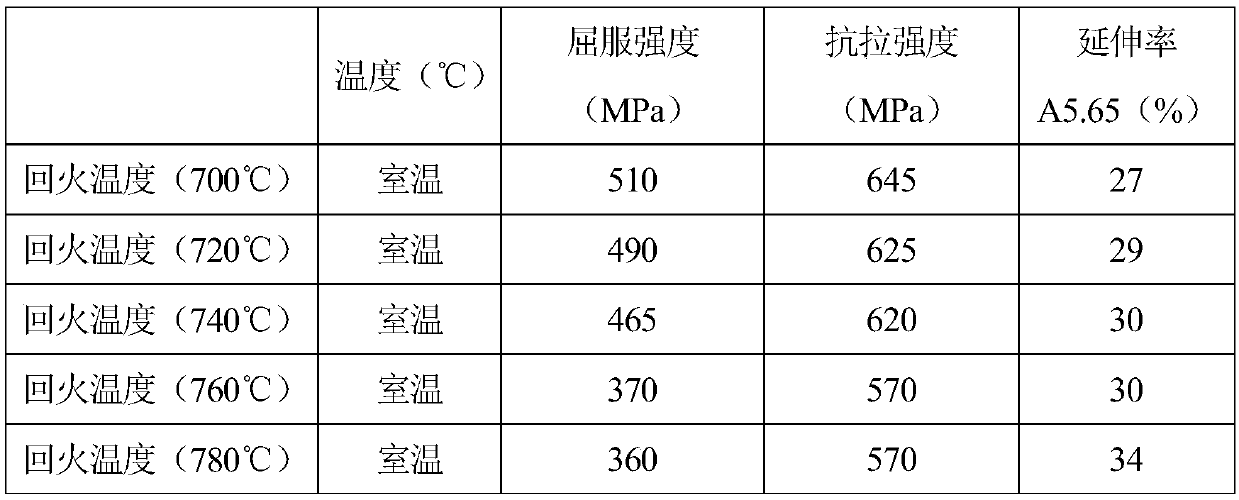

[0050] The metal seamless composite pipe of this embodiment is a three-layer composite of FeCrAl (outer layer) / Fe alloy (transition layer) / T91 (inner layer), and the FeCrAl alloy composition is: Cr 12.5wt%, Al 4.2wt%, Nb 0.3wt% %, Fe surplus; transition layer is ferroalloy divided into: C 0.01wt%, Nb 0.3wt%, Si 0.1wt%, Mn0.2wt%, Fe surplus; inner layer is T91 (P91) alloy. Its specification is Φ9.5mm (outer diameter) × 0.5mm (wall thickness), and the main preparation process is as follows:

[0051] (1) Tube blank polishing: Polish the inner and outer surfaces of the outer tube, transition tube, and inner tube to Ra0.1μm respectively, and the gap between the tubes in each layer is about 0.1mm.

[0052] (2) Tube billet assembly and packaging: the polished FeCrAl, Fe alloy, and T91 tube billet are drawn and assembled with mandrel layer by layer. After the outer tube and the inner tube are assembled, the shrinking process of the tube head is carried out at the same time. Then dra...

Embodiment 2

[0065] The metal seamless composite pipe of this embodiment is a three-layer composite of FeCrAl (outer layer) / Fe alloy (transition layer) / T91 (inner layer), and the FeCrAl alloy composition is: Cr 13.1wt%, Al 4.0wt%, V 0.2wt% %, Fe surplus; transition layer is ferroalloy divided into: C 0.005wt%, V 0.3wt%, Si 0.15wt%, Mn0.2wt%, Fe surplus; inner layer is T91 (P91) alloy. Its specification is Φ9.5mm (outer diameter) × 0.5mm (wall thickness), and the main preparation process is as follows:

[0066] (1) Polishing of the tube blank, polishing the inner and outer surfaces of the outer tube, transition tube, and inner tube respectively to Ra0.1μm, and the gap between the tubes of each layer is -0.1mm.

[0067] (2) The tube blank is assembled and packaged. The Fe alloy (transition layer) tube is immersed in a low-temperature liquid nitrogen solution. The transition tube shrinks at low temperature. After cleaning, it is assembled into the FeCrAl (outer layer) tube. When it returns t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com