Quality detecting device and method based on IC bonding wire

A technology of bonding wire and detection device, which is applied in the direction of measurement device, measurement of electricity, measurement of electric variables, etc., can solve the problem of no longer applicable to quality detection of bonding wire and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

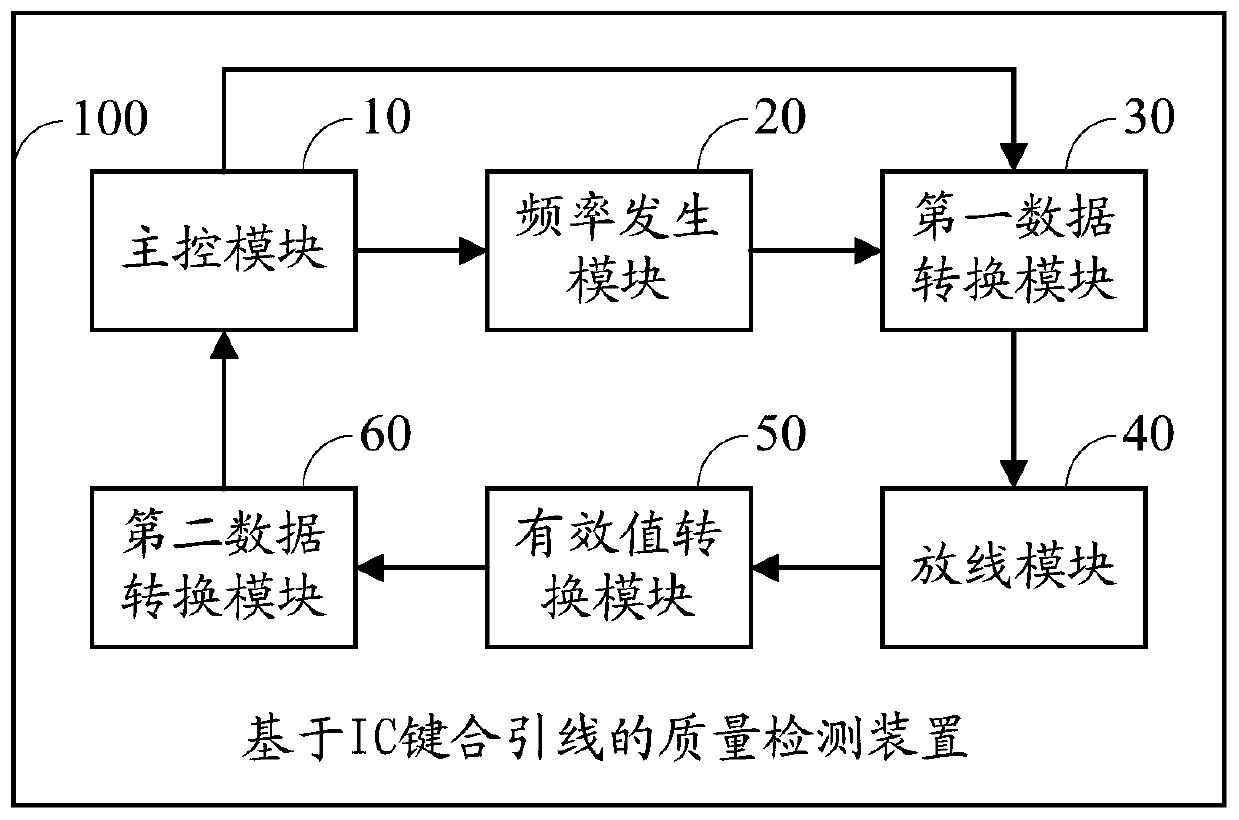

[0050] like figure 1 As shown, the embodiment of the present invention provides an IC-based bonding wire quality detection device 100 for detecting the quality of IC-based bonding wires. The quality inspection device 100 based on IC bonding wires includes but not limited to: a main control module 10 , a frequency generation module 20 , a first data conversion module 30 , a pay-off module 40 , an effective value conversion module 50 and a second data conversion module 60 .

[0051] In the embodiment of the present invention, the connection relationship of the above modules is as follows:

[0052] The main control module 10, the frequency generation module 20, the first data conversion module 30, the pay-off module 40, the effective value conversion module 50 and the second data conversion module 60 are connected end to end in sequence, and the main control module 10 is also connected with the first data conversion module 30 Connection; the main control module 10 controls the f...

Embodiment 2

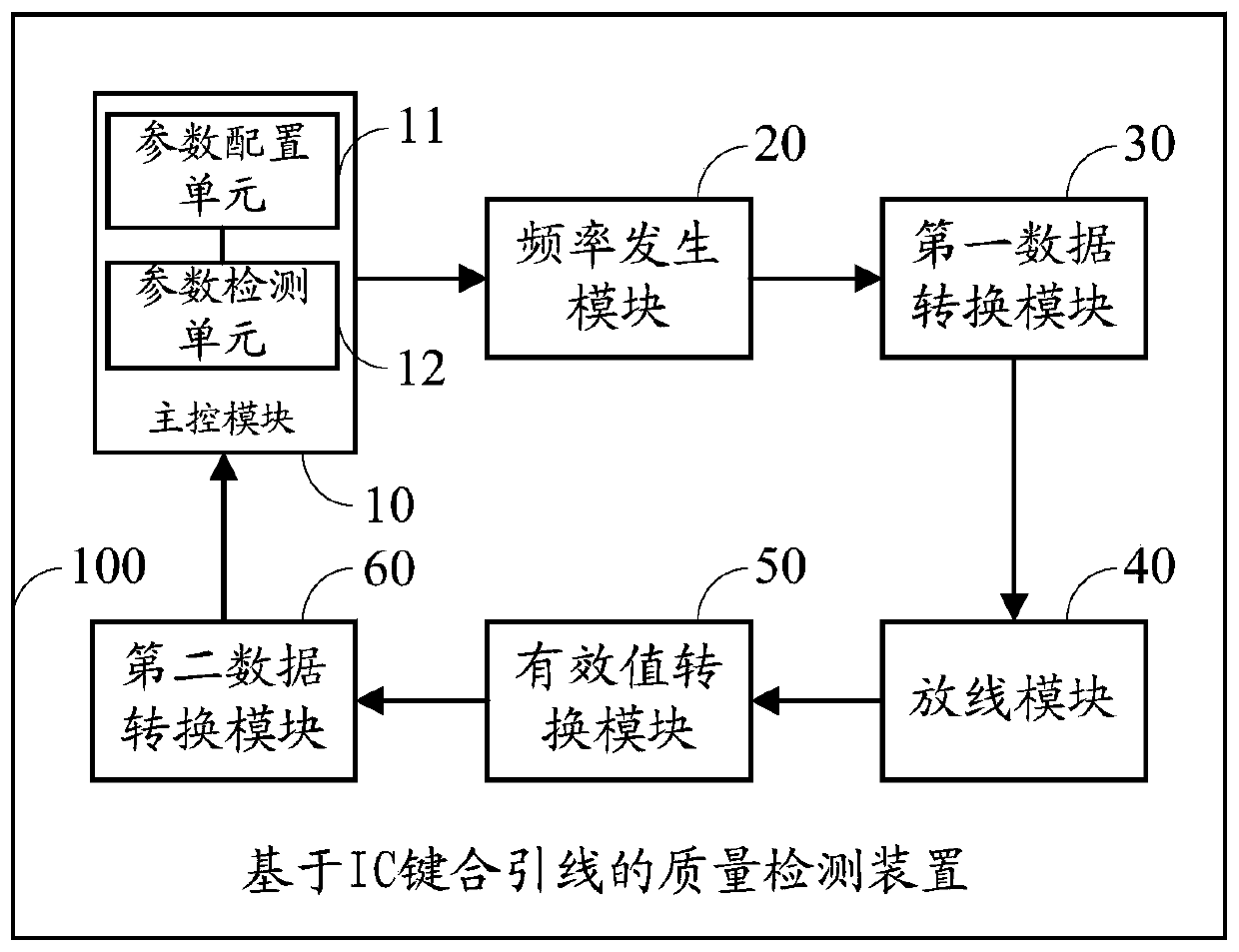

[0076] like figure 2 As shown, the main control module 10 in the first embodiment includes a parameter configuration unit 11 .

[0077] The parameter configuration unit 11 is used to adjust the parameter configuration of the main control module according to the working frequency of the IC, and control the frequency signal output by the frequency generation module and the amplitude of the AC signal output by the first data conversion module.

[0078] In a specific application, the frequency generation module can generate different frequency signals according to different parameter configurations of the main control module. In the embodiment of the present invention, by configuring the parameter configuration of the main control module, the output quantity of one of the input and output ports is changed, so that the frequency signal output by the frequency generation module is suitable for the current operating frequency of the IC. Then use this frequency signal as the referen...

Embodiment 3

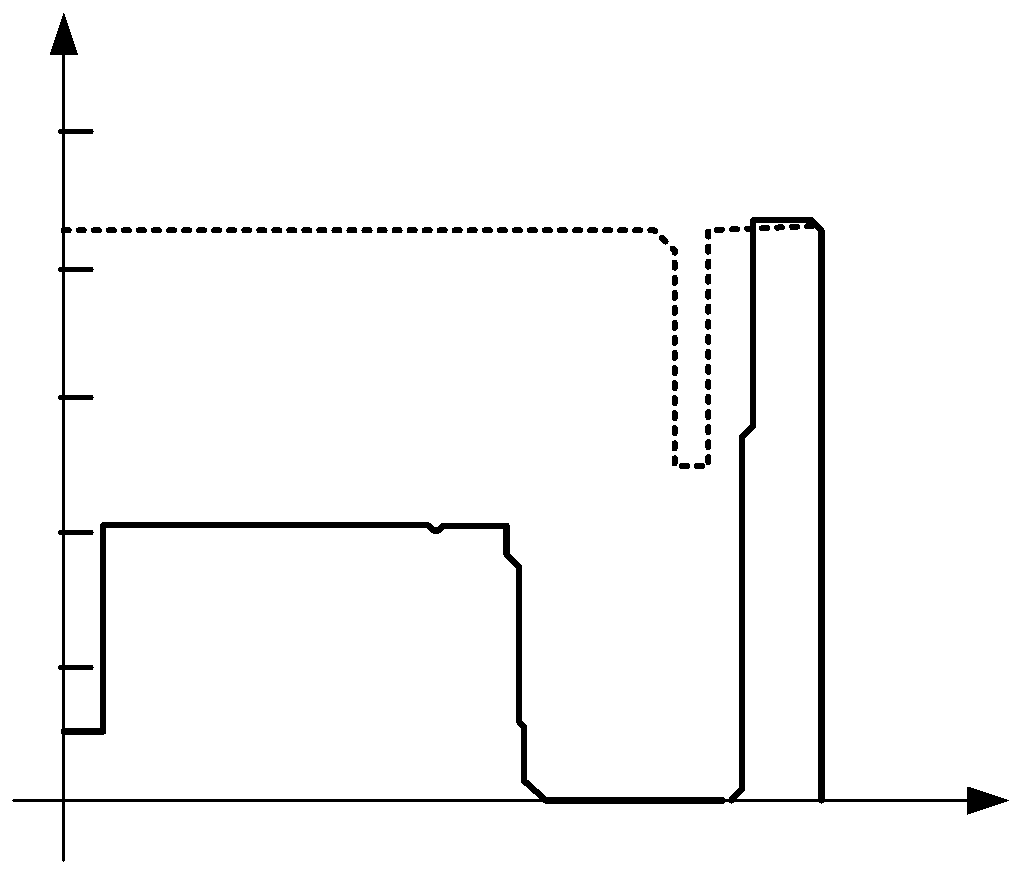

[0085] In the embodiment of the present invention, through the quality inspection device based on the IC bonding wire in the first embodiment above, the obtained quality inspection results of the IC bonding wire include: the first welding inspection result, the wire tail inspection result and the second Weld inspection results.

[0086] Wherein, when the pay-off module places the first welding spot, the main control module outputs the first welding detection result.

[0087] After placing the first solder joint in the pay-off module, when leaving the end of the line, the main control module outputs the detection result of the end of the line;

[0088] After the second welding spot is placed by the pay-off module, when the wire is broken, the main control module outputs the second welding detection result.

[0089] In one embodiment, the quality inspection device based on IC bonding wires further includes a display module.

[0090] Wherein, the display module is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com