Screen and preparation method of light-absorbing film

A screen and light film technology, applied in optics, flat products, instruments, etc., can solve the problems of complex process, low yield, low optical efficiency, etc., to increase the bonding strength between layers, increase productivity, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Hereinafter, specific embodiments according to the present invention will be described in detail with reference to the accompanying drawings. It should be emphasized that all dimensions in the drawings are only schematic and not necessarily shown in true scale, and thus are not limiting. For example, it should be understood that the thickness and thickness ratio of each layer in the multilayer structure of the projection screen shown in the figure are not shown according to the actual size and ratio, but are only for the convenience of illustration.

[0056] 1. Overview of total reflection projection system

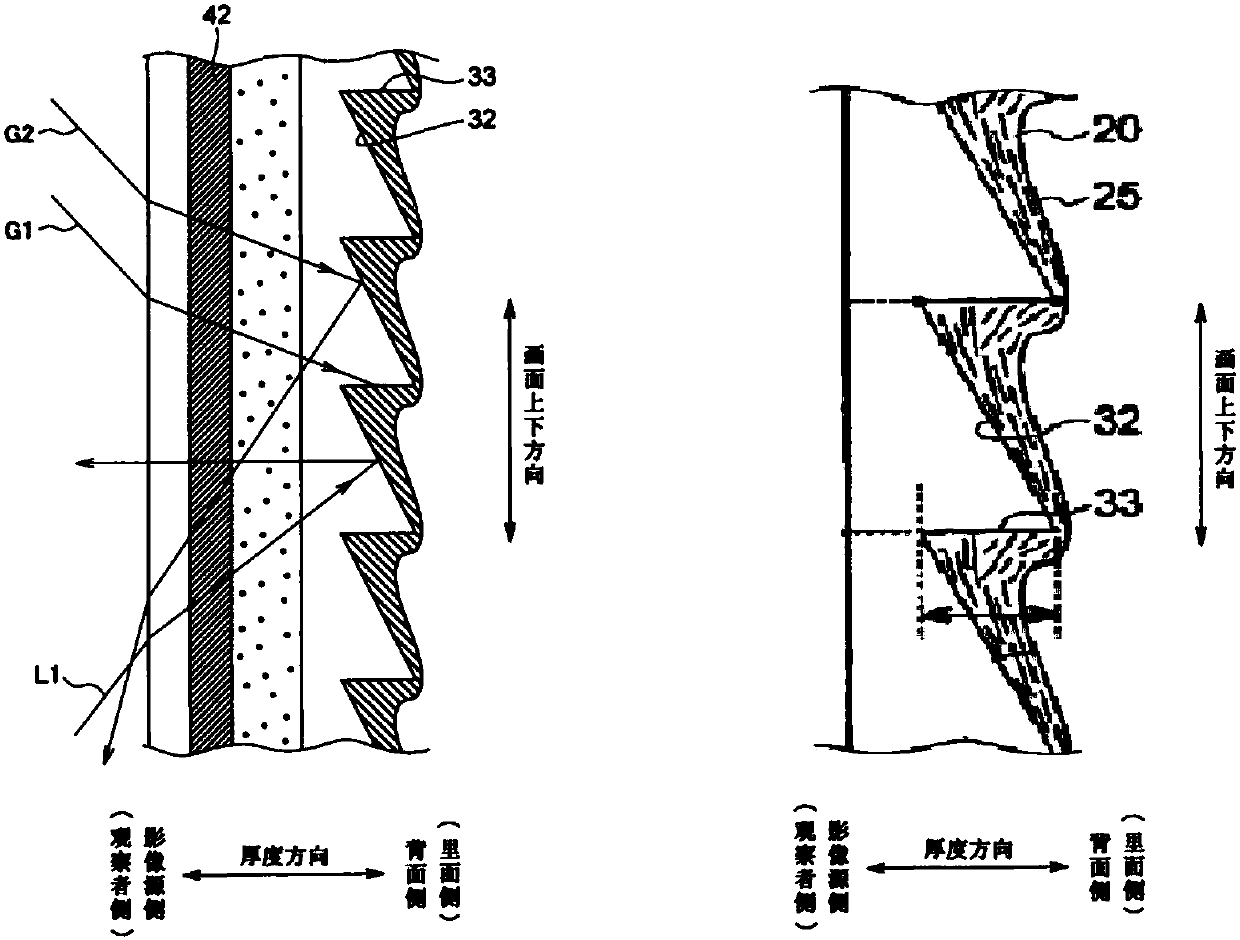

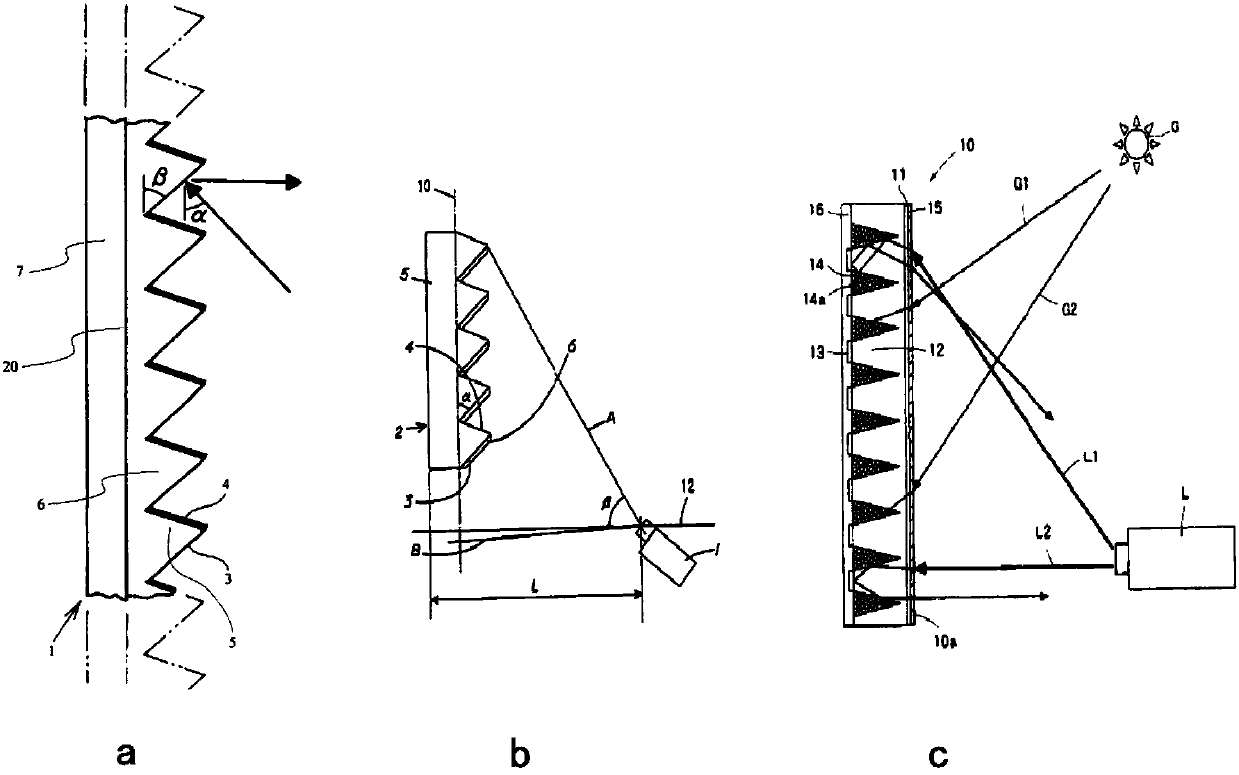

[0057] image 3 is a schematic structural diagram showing a projection system according to an embodiment of the present invention. Such as image 3 As shown in , the projection system includes a screen 10 and a projector 20 . The screen 10 includes a surface total reflection layer 14, a volume diffusion layer 13, an optical function layer 12, and a light absor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com