One-pot method for preparing gamma-Al2O3 supported Au-Pd catalyst

A catalyst, au-pd technology, applied in the field of preparation of γ-Al2O3-loaded Au-Pd catalyst, can solve the problems of easy sintering of metal nanoparticles, difficult control of conditions, cumbersome synthesis process, etc., and achieve excellent selective oxidation performance of benzyl alcohol , The synthesis process is simple and easy, and the preparation process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

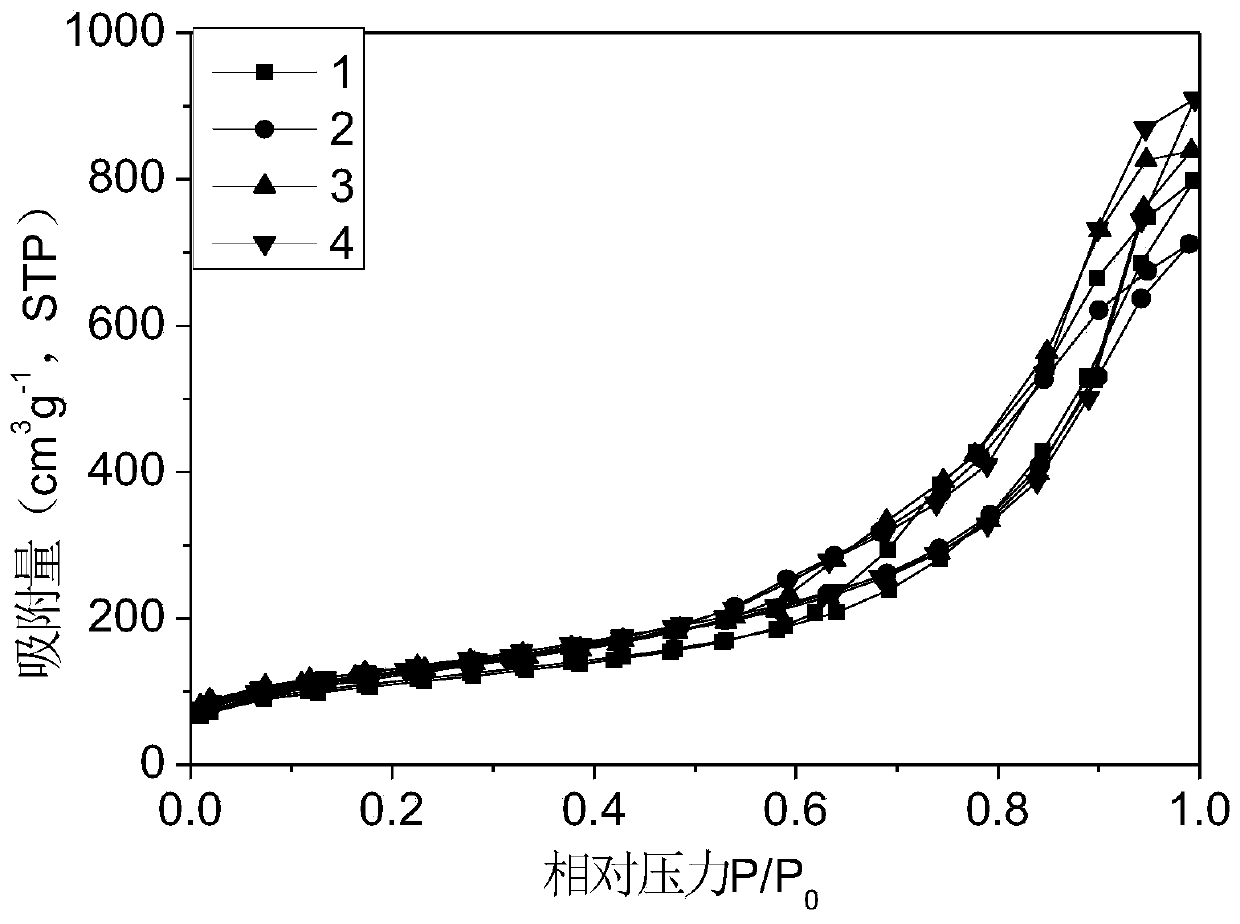

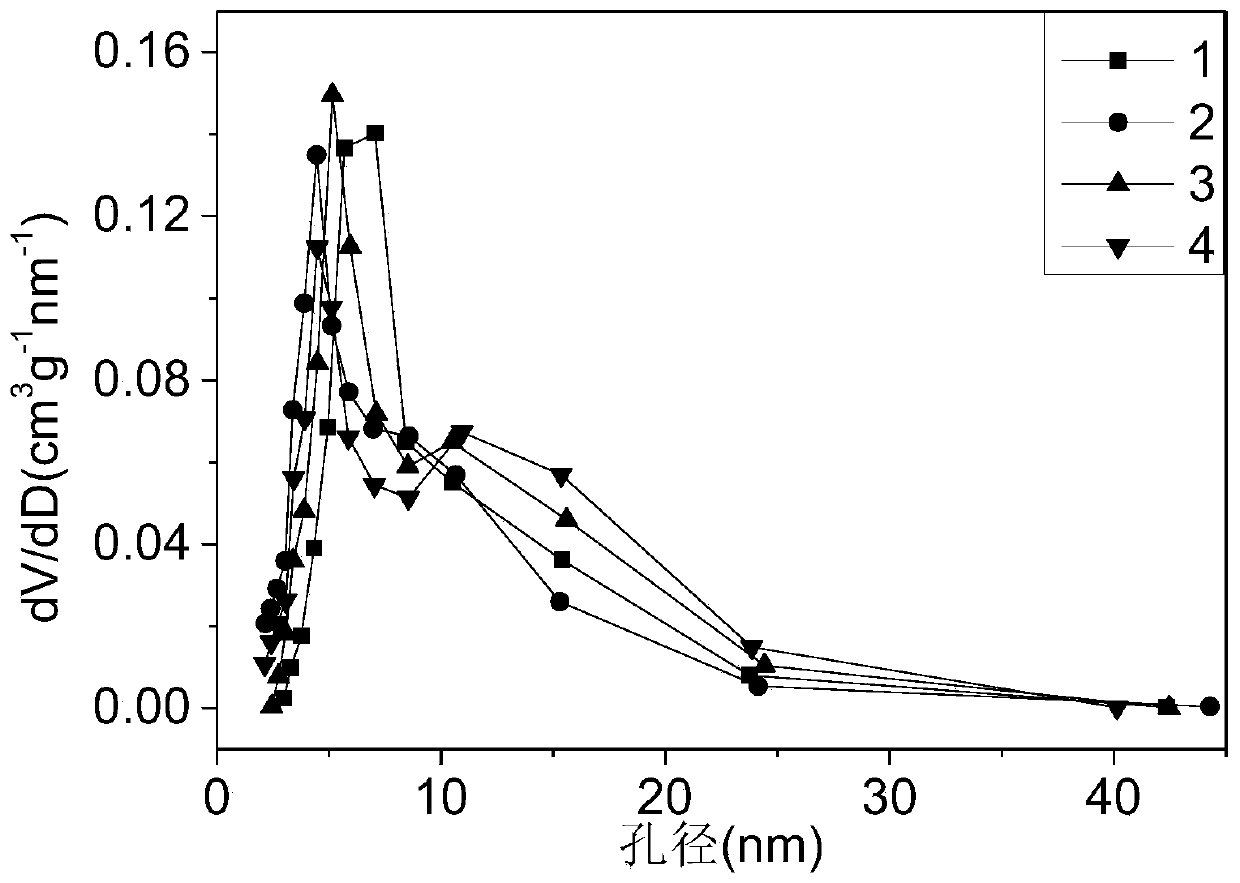

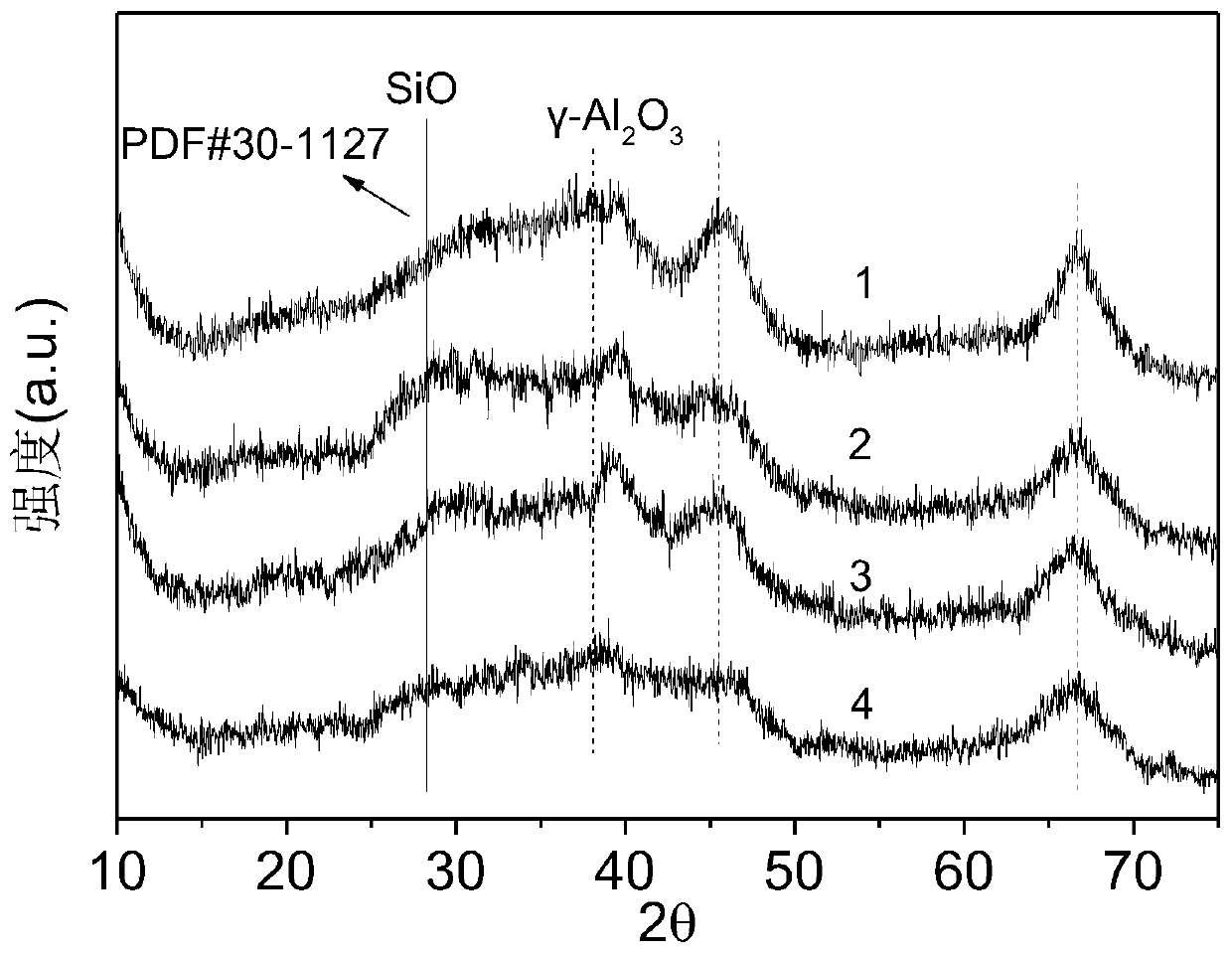

[0024] Example 1: At room temperature, 2.414g AlCl 3 ·6H 2 O and 2.28 g NaAlO 2 Dissolve in 25ml distilled water. in AlCl 3 Add 0.41g MPTMS dropwise in the solution, according to Al 2 o 3 The mole of / MPTMS is equal to 10:1; the AlCl 3 with NaAlO 2 The solution was poured into a beaker in parallel to produce a white precipitate. The resulting mixture was stirred at room temperature for 1.5h, and 2.1ml of 0.024mol / L PdCl was slowly added dropwise. 2 solution and 4.25ml of 0.024mol / L HAuCl 4Suction filtration and washing are then performed to obtain an aluminum hydroxide colloid filter cake containing Au and Pd precursors. Add 2.5g of P123 to 25ml of deionized water, stir until clear, then mix the P123 solution with the aluminum hydroxide colloidal filter cake, beat and stir for 4h. The beaten product was dried in an oven at 100°C for 12 hours, then heated to 500°C in a muffle furnace at a rate of 2°C / min, and then roasted at a constant temperature of 500°C for 3 hours....

Embodiment 2

[0025] Embodiment 2: at room temperature, respectively 2.414g AlCl 3 ·6H 2 O and 2.28 g NaAlO 2 Dissolve in 25ml of distilled water respectively. in AlCl 3 Add 0.26g MPTMS dropwise in the solution, according to Al 2 o 3 The molar ratio of / MPTMS is equal to 15; the AlCl 3 with NaAlO 2 The solution was poured into a beaker in parallel to produce a white precipitate. The resulting mixture was stirred at room temperature for 1.5 h, and 2.1 ml of 0.024 mol / L PdCl was slowly added dropwise. 2 solution and 4.25ml, 0.024mol / L of HAuCl 4 Suction filtration and washing are then performed to obtain an aluminum hydroxide colloid filter cake containing Au and Pd precursors. Add 2.5g of P123 to 25ml of deionized water, stir until clear, then mix the P123 solution with the aluminum hydroxide colloidal filter cake, beat and stir for 4h. The beaten product was dried in an oven at 100°C for 12 hours, then heated to 500°C in a muffle furnace at a rate of 2°C / min, and then roasted at a ...

Embodiment 3

[0026] Embodiment 3: at room temperature, respectively 2.414g AlCl 3 ·6H 2 O and 2.28 g NaAlO 2 Dissolve in 25ml of distilled water respectively. in AlCl 3 Add 0.26g MPTMS dropwise in the solution, according to Al 2 o 3 The molar ratio of / MPTMS is equal to 20; the AlCl 3 with NaAlO 2 The solution was poured into a beaker in parallel to produce a white precipitate. The resulting mixture was stirred at room temperature for 1.5 h, and 2.1 ml of 0.024 mol / L PdCl was slowly added dropwise. 2 solution and 4.25ml, 0.024mol / L of HAuCl 4 Suction filtration and washing are then performed to obtain an aluminum hydroxide colloid filter cake containing Au and Pd precursors. Add 2.5g of P123 into 25ml of deionized water, stir until clear, then mix the P123 solution with the aluminum hydroxide colloidal filter cake, beat and stir for 4h. The beaten product was dried in an oven at 100°C for 12 hours, then heated to 500°C in a muffle furnace at a rate of 2°C / min, and then roasted at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com