An isothermal hot drawing forming device and forming method for controlling component wall thickness uniformity

A technology for controlling components and uniformity, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as bottom thinning and uneven deformation of blanks, achieve uniform deformation, eliminate uneven deformation, and bottom thinning Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

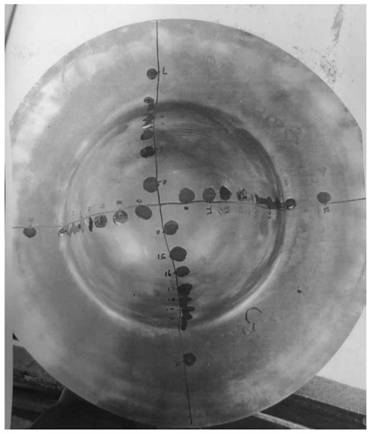

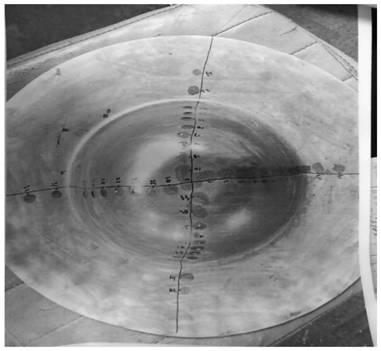

Image

Examples

specific Embodiment approach 1

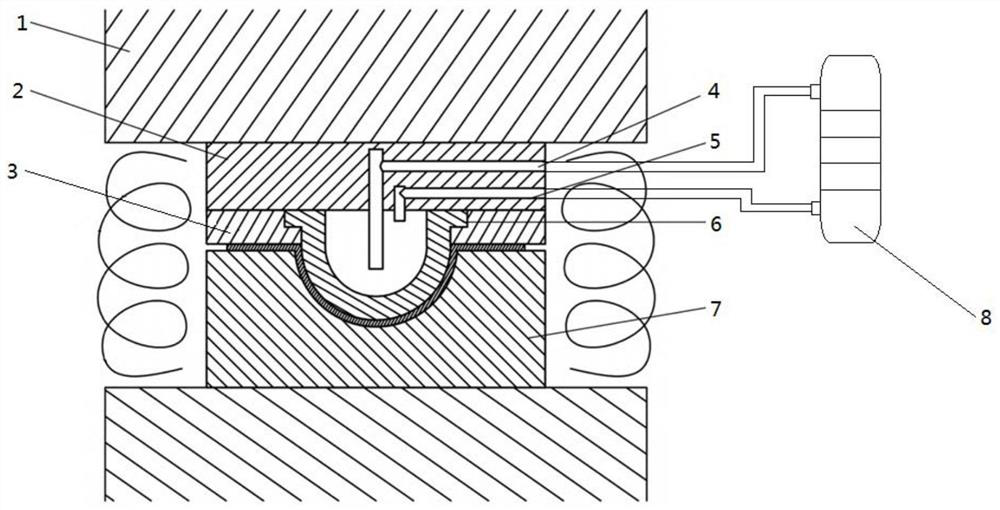

[0029] Specific implementation mode one: combine figure 1 To illustrate, this embodiment is an isothermal deep-drawing forming device for controlling the uniformity of the wall thickness of a component, including a thermoforming press 1, a mold and a gas cooler 8, wherein the mold includes a template 2, a fixed plate 3, an air inlet pipe 4, an outlet Air pipe 5, punch 6 and die 7; template 2 is assembled on the hot pressing plate on the upper side of the thermoforming press 1, and the die 7 is assembled on the lower hot pressing plate of the thermoforming press 1, and the punch 6 passes through The fixed plate 3 and the template 2 are airtightly fixed, the inside of the punch 6 is provided with a cavity, the punch 6 is arranged above the die 7, the axes of the punch 6 and the die 7 coincide, and the inside of the template 2 An air inlet pipe 4 and an air outlet pipe 5 are provided. One end of the air inlet pipe 4 extends into the cavity of the punch 6 and is close to the botto...

specific Embodiment approach 2

[0031] Embodiment 2: This embodiment differs from Embodiment 1 in that the depth of the air outlet pipe located in the cavity of the punch 6 is smaller than the depth of the air inlet pipe.

specific Embodiment approach 3

[0032] Specific embodiment 3: The forming method of the isothermal hot drawing forming device for controlling the uniformity of the wall thickness of the component described in the specific embodiment 1 is specifically carried out according to the following steps:

[0033] 1. Install the mold on the thermoforming press;

[0034] 2. Heat the thermoforming press to the thermoforming temperature, put in the sheet material, keep it warm for 10-60 minutes, and then pass the cooling gas into the punch through the air inlet pipe. When the temperature of the punch drops to the bottom preforming temperature, deep drawing is carried out Forming, after the punch and die are closed, stop feeding the cooling gas, keep the pressure for 5 to 30 minutes, and raise the temperature of the punch to the thermoforming temperature;

[0035] 3. Open the mold, take out the formed parts, cool to room temperature, inspect and accept the parts, and complete an isothermal hot drawing forming method that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com