Electrostatic minimum quantity lubrication device

A technology of micro-lubrication and charging device, which is applied in the direction of metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc. It can solve the problems of poor processing performance, high oil mist concentration, and overall excessive size, and achieve small particle size and wetting angle, high cooling and lubricating ability, and simplified post-processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

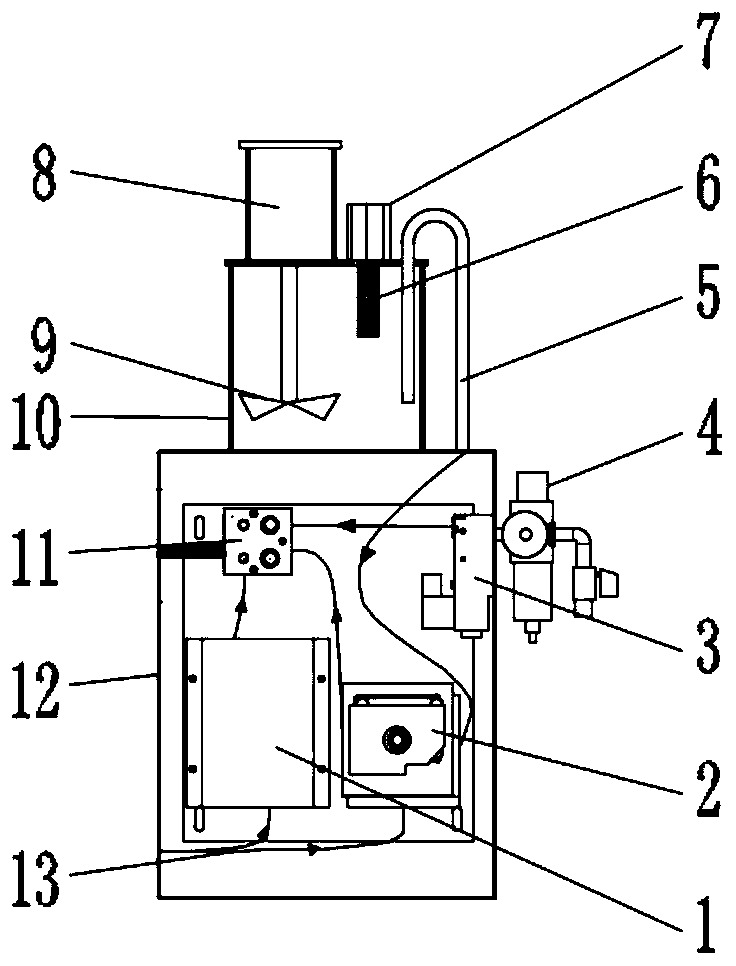

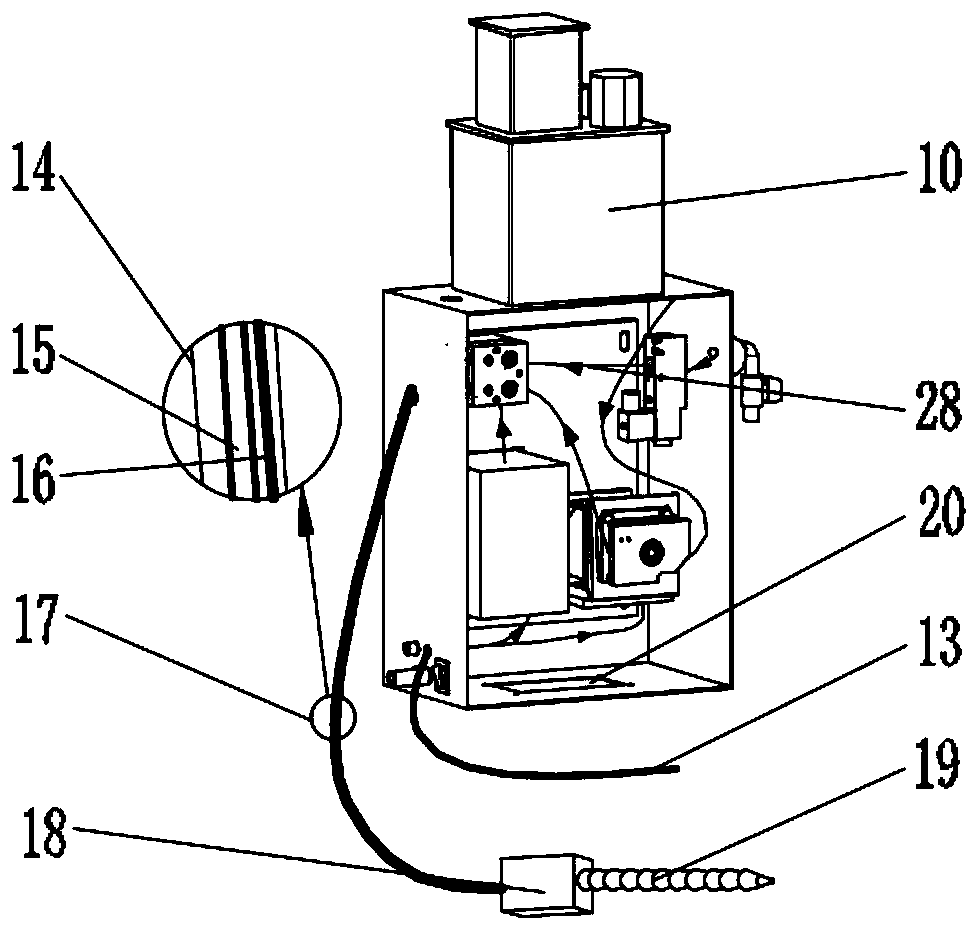

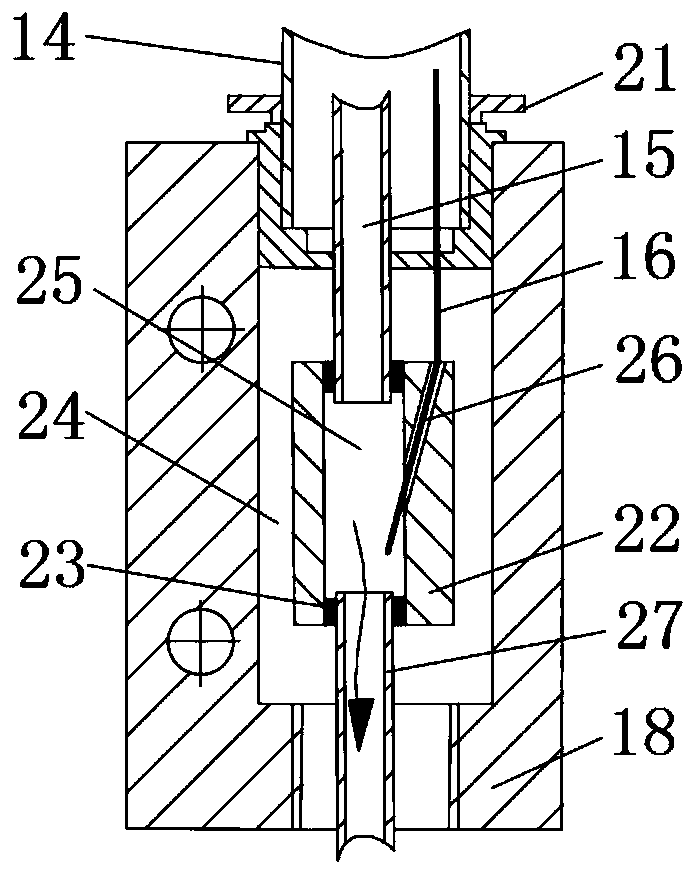

[0027] An electrostatic micro-lubrication device according to an embodiment of the present invention is characterized in that it includes a box body 12, an electrostatic generating device 1, a liquid supply device 2, a second air pipe 14, a gas-liquid-electric confluence device 11, and a gas-liquid-electric transmission pipe 17. Charging device 18, nozzle 19; gas-liquid-electric confluence device 11 is installed in the box body 12, the material used is POM material with good insulation and processability, and one end is provided with a liquid inlet, an air inlet, and a power inlet. The other end is provided with gas, liquid and electricity outlets, and each port is connected to various pipelines through joints. Electrostatic generator 1 includes an electrostatic generator and an overload protection device. The electrostatic generator can provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com