Preparation method of ZnS nanosheets

A nanosheet and suspension technology, applied in nanotechnology, zinc sulfide and other directions, can solve the problems of high energy consumption, complex process, low yield, etc., and achieve the effects of low energy consumption, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

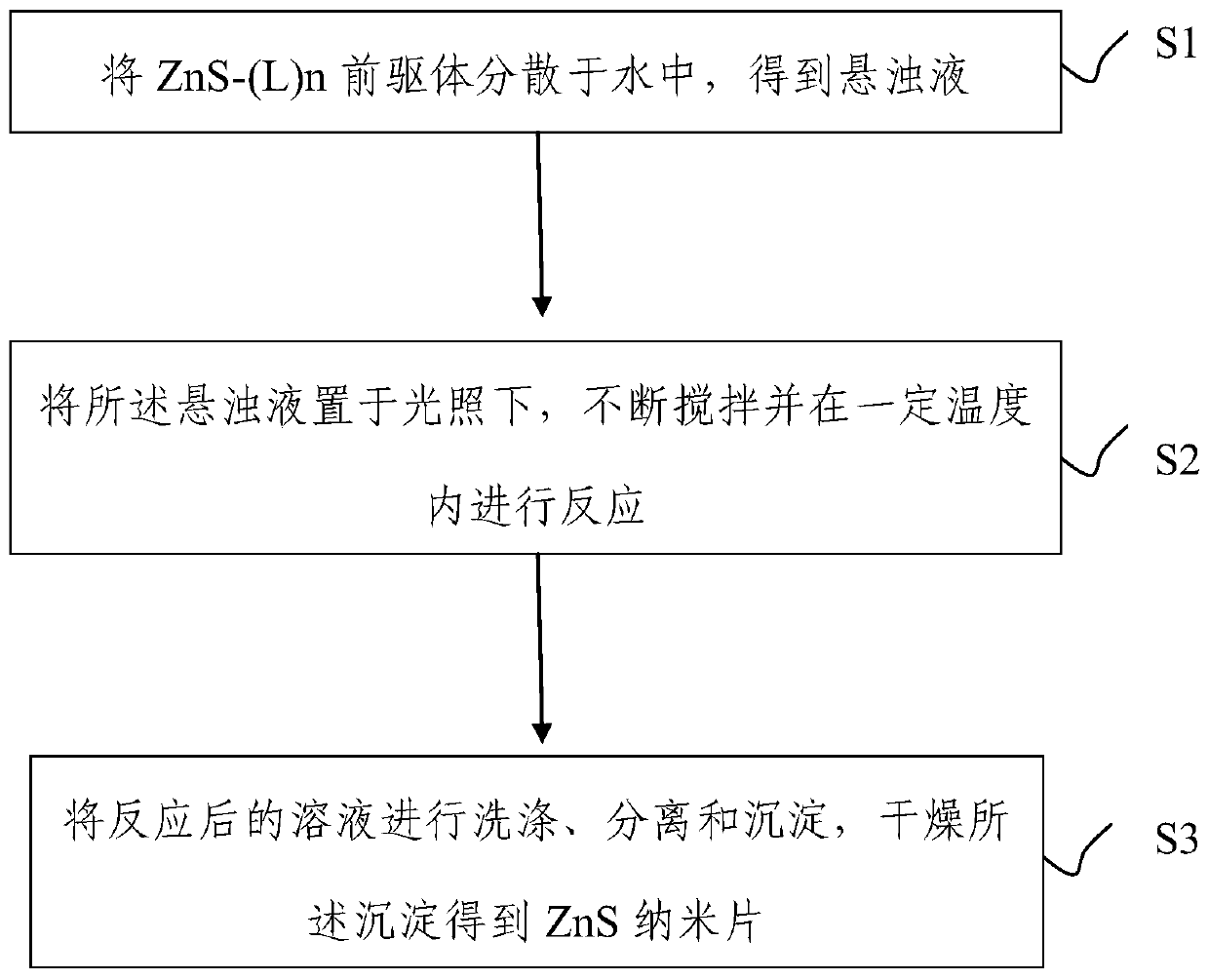

[0038] The invention provides a kind of preparation method of ZnS nano sheet, comprises the steps:

[0039] S1, dispersing the ZnS-(L)n precursor in water to obtain a suspension;

[0040] S2, placing the suspension under light, stirring continuously and reacting at a certain temperature;

[0041] S3, washing, separating and precipitating the reacted solution, drying the precipitate to obtain ZnS nanosheets;

[0042] Wherein, L in the ZnS-(L)n is a compound containing a single or multiple amino groups, and n is 0.5-1.

[0043] The present invention has no special limitation on the source of all raw materials, which can be commercially available.

[0044] The L in the ZnS-(L)n is an organic compound containing an amino functional group well known to those skilled in the art, and there is no special limitation. The L in the present invention is preferably ethylenediamine (en), cyclohexanediamine One or more of amine and o-phenylenediamine, more preferably ethylenediamine; n in...

Embodiment 1

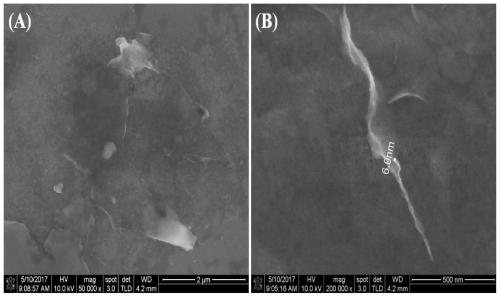

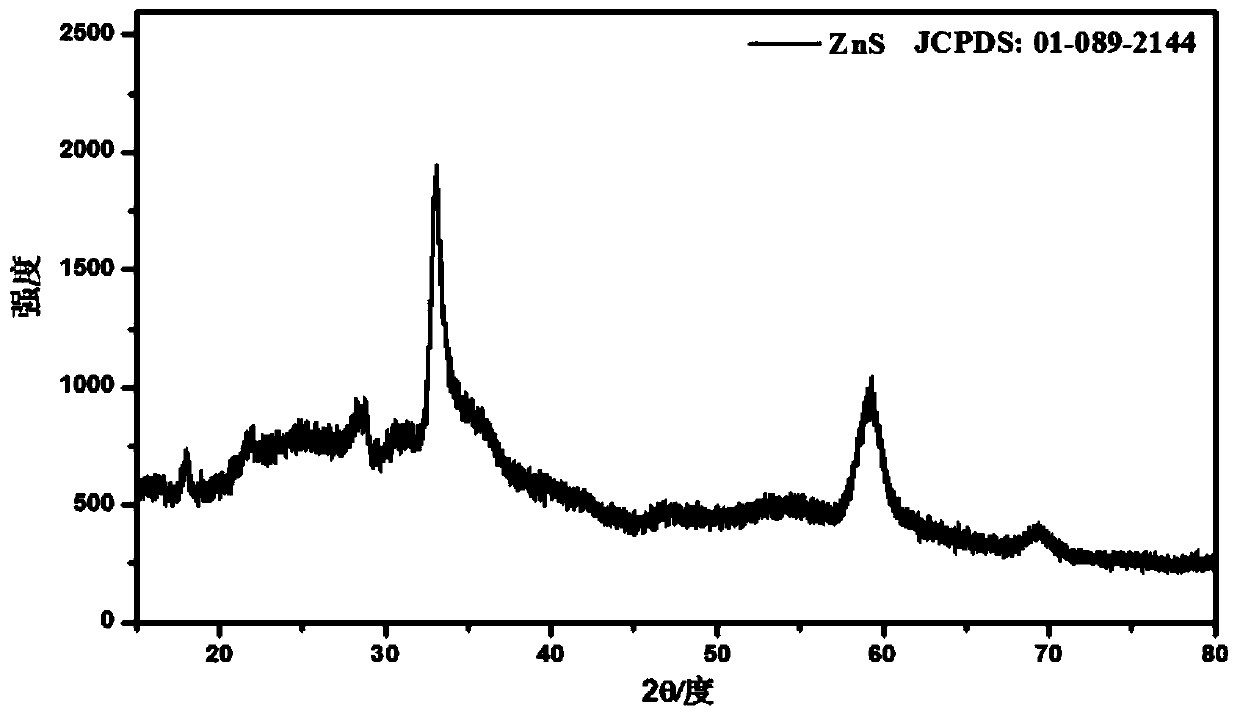

[0055] Weigh homemade 5mg ZnS(en) 0.5 The precursor was dispersed in 10 mL of water to obtain a suspension; the obtained suspension was irradiated under a low-pressure mercury lamp for 2 h, and the suspension was stirred continuously during the irradiation process and the temperature of the reaction system was kept at room temperature; then deionized water and The ethanol was washed, separated, the precipitate was collected, and dried to obtain a ZnS nanosheet sample.

Embodiment 2

[0057] Weigh homemade 200mg ZnS(en) 0.5The precursor was dispersed in 200mL of water to obtain a suspension; the resulting suspension was irradiated under a low-pressure mercury lamp for 24 hours, and the suspension was constantly stirred during the irradiation process and the temperature of the reaction system was kept at room temperature; then deionized water and The ethanol was washed, separated, the precipitate was collected, and dried to obtain a ZnS nanosheet sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Plane size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com