Method for preparing polycarbonate polyol and composition comprising the polycarbonate polyol

A polyol composition, polycarbonate technology, applied in the direction of silicate, magnesium silicate, alkali metal silicate, etc., can solve problems such as affecting the properties of polycarbonate polyol products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

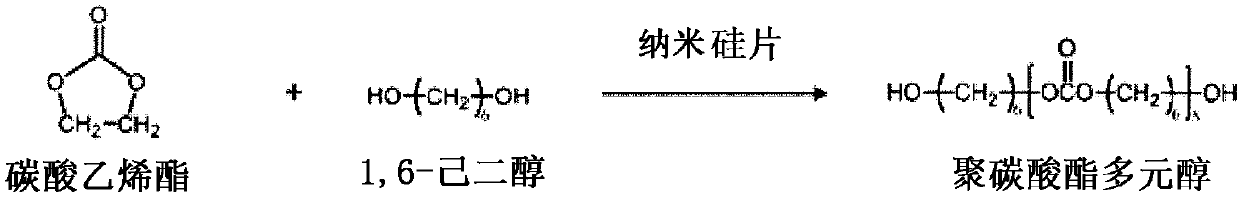

Method used

Image

Examples

Embodiment 1

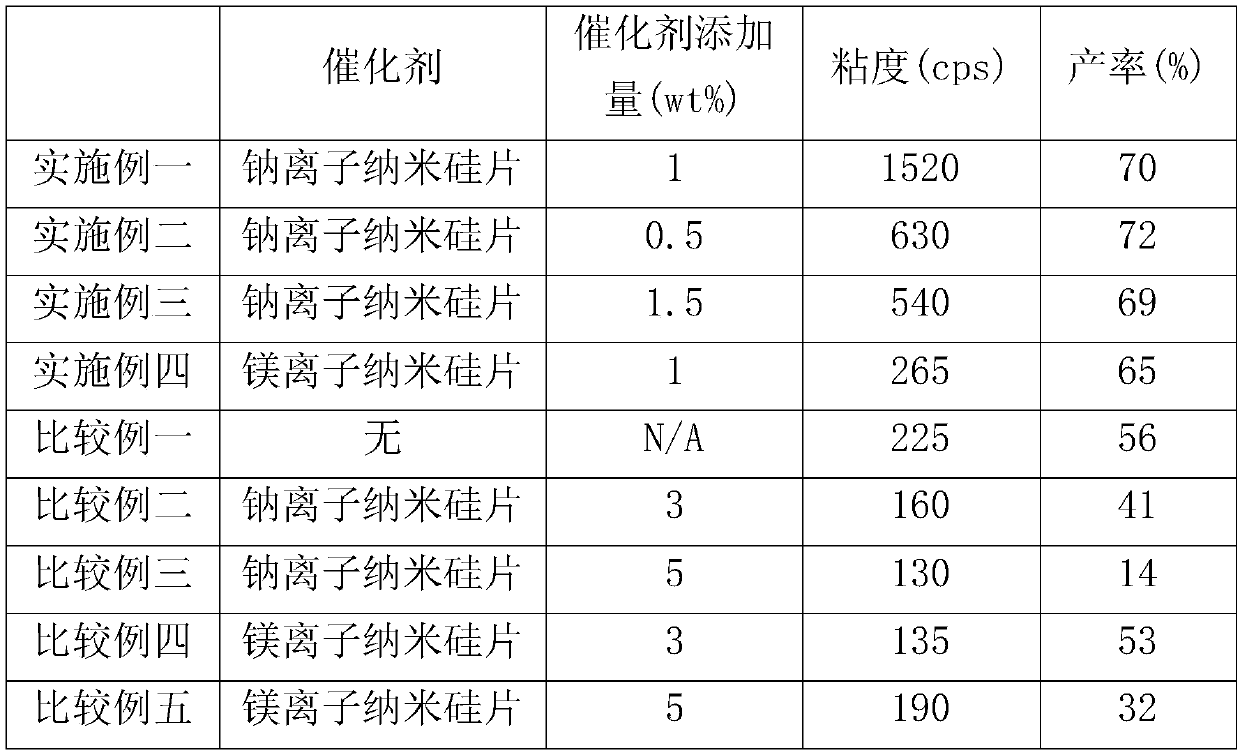

[0026]In a reactor with a mechanical stirrer, a heating mantle, a Dean-Stark Trap, a water-cooled condenser and a vacuum pump, 1,6-hexanediol (58.66 g; 0.50 mole ), ethylene carbonate (41.04g; 0.47mole) and 1 gram of nano-silicon chips with sodium ions as a catalyst, the addition amount is 1wt%, and then enters stage one, under the condition of nitrogen gas and the absolute pressure is maintained at 760torr, heated to 100°C, use mechanical stirring (500rpm) for 0.5 hours, enter stage 2, raise the temperature to 150°C for 1 hour, enter stage 3, and then raise the temperature to 180°C for 4 hours. Then, enter the fourth stage, the reactor is evacuated by a pump, the temperature is kept at 180°C, and the vacuum value is reduced from 760torr (ie 1atm; 760mm-Hg) to 100torr after 1 hour of reaction, the lower boiling point can be observed (196°C) ethylene glycol (EG) was removed by a Dean-Stark separator. Finally, enter stage five, then reduce the vacuum value to 50torr and continu...

Embodiment 2

[0028] The preparation method conditions of embodiment two are as described in embodiment one, except that the consumption of sodium ion nano-silicon flakes is changed to 0.5wt% in addition to the catalyst, and the polycarbonate polyol with nano-silicon flakes is centrifuged to remove nano-silicon flakes to obtain 72.82 grams of polycarbonate polyol, brown in color, semi-solid at room temperature, 72% yield. The viscosity is 630cps.

Embodiment 3

[0030] The preparation method conditions of embodiment three are as described in embodiment one, except that the consumption of sodium ion nano-silicon flakes is changed to 1.5wt% in addition to the catalyst, and the polycarbonate polyol with nano-silicon flakes is centrifuged to remove nano-silicon flakes to obtain 69.89 g of polycarbonate polyol, brown in color, semi-solid at room temperature, 69% yield. The viscosity is 540cps.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com