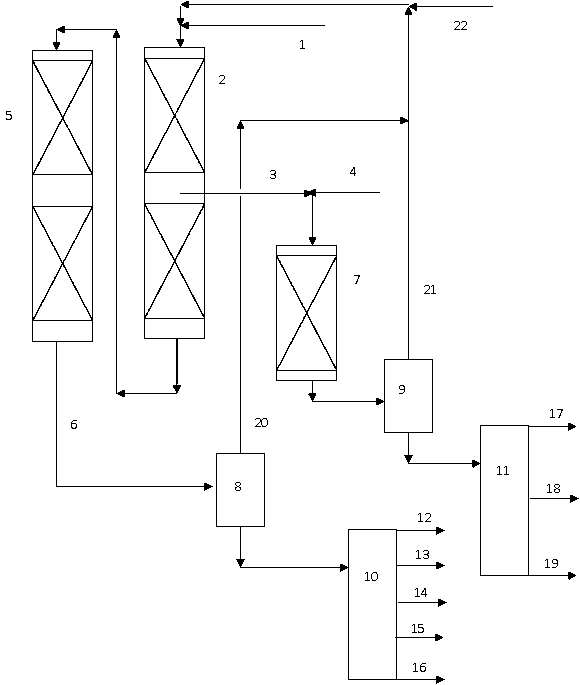

Hydrotreating and hydrocracking combined process

A technology of hydrogenation treatment and combination process, which is applied in the direction of hydrogenation treatment process, hydrocarbon oil treatment, hydrocarbon oil treatment products, etc., which can solve the problem of less combined processing technology, no combined processing technology of reactive materials, and the inability to effectively control the depth of LCO hydrogenation and other problems, to achieve the effect of easy realization and increase of octane number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0045] Protective agents FZC-100, FZC-105 and FZC106 are hydrogenation protective agents developed and produced by Sinopec Fushun Petrochemical Research Institute; catalyst FF-56 is developed and produced by Sinopec Fushun Petrochemical Research Institute Hydrotreating catalyst; Catalyst FC-32 is a hydrocracking catalyst developed and produced by Sinopec Fushun Petrochemical Research Institute, containing Y-type molecular sieve; Catalyst FF-24 is Sinopec Fushun Petrochemical Research Institute Hydrotreating catalyst developed and produced.

[0046] Table 1 Main properties of wax oil feedstock

[0047] wax oil 1 wax oil 2 LCO Density, g / cm 3

0.901 0.921 0.932 Distillation range, ℃ 320~545 345~575 156~370 Sulfur content, wt% 1.15 2.23 1.3 Nitrogen content, wt% 0.127 0.082 0.09 Aromatic content, wt% — — 91.2

[0048] Table 2 process conditions

[0049]

[0050] Continued Table 2 Process Conditions

[0051]

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com