Patents

Literature

67results about How to "Implement coupled operations" patented technology

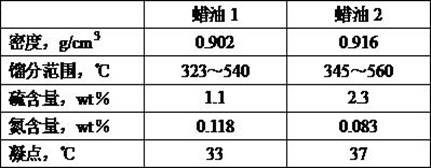

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

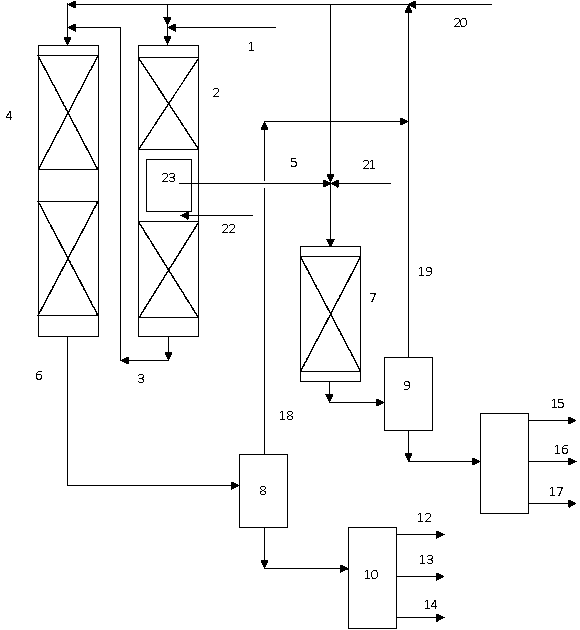

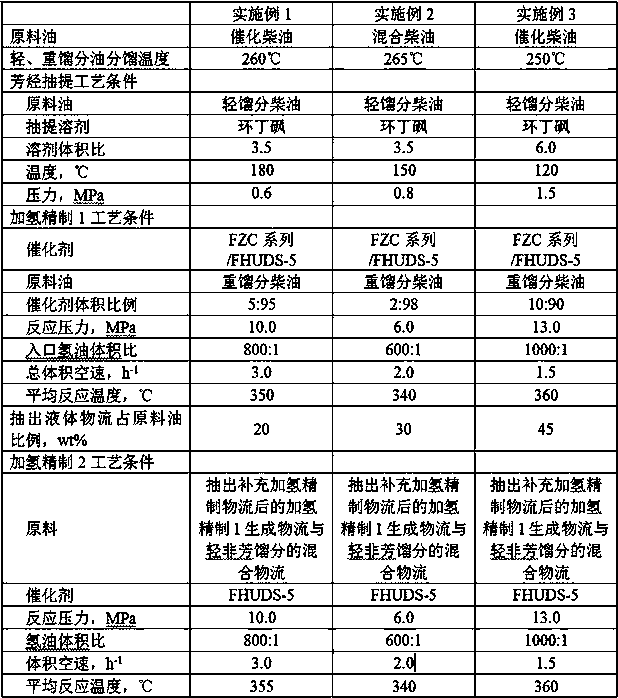

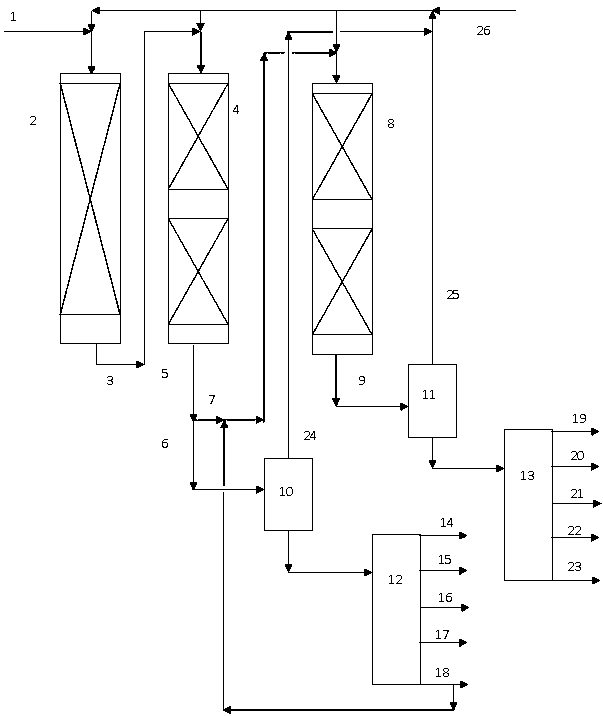

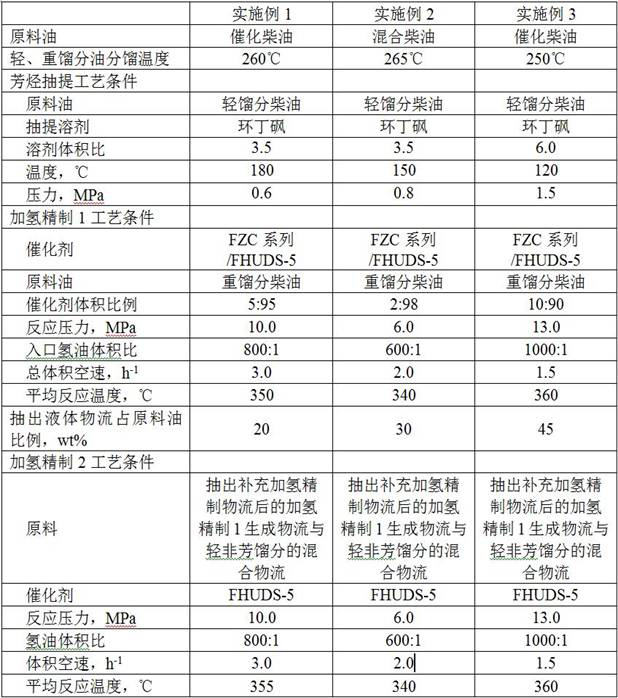

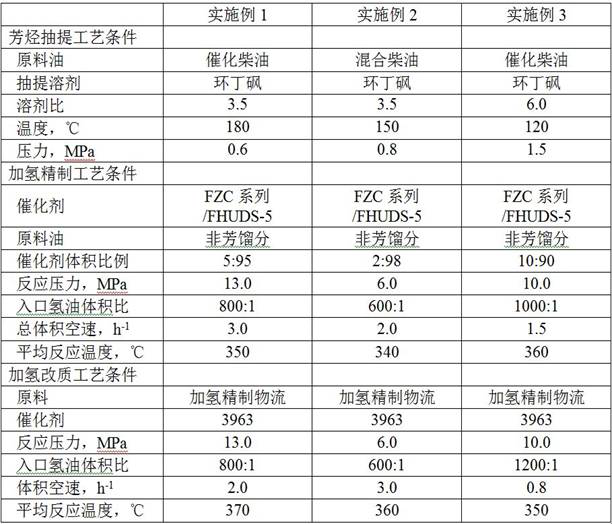

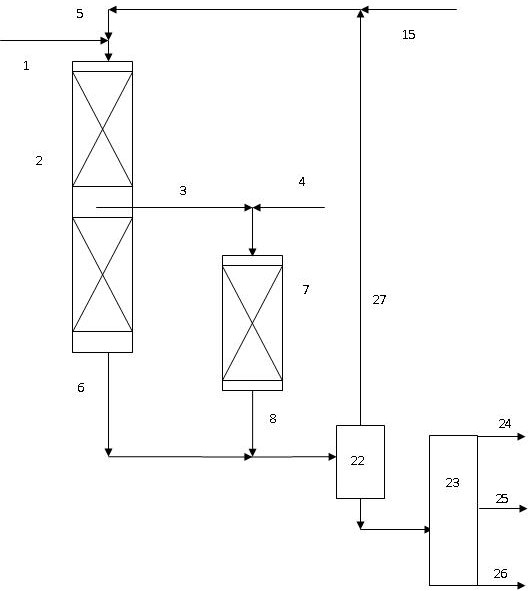

An inferior diesel oil hydro-upgrading and hydrofining combined process

ActiveCN109988645AFlexible production methodsEffective distributionTreatment with hydrotreatment processesHydrocarbon oils treatment productsFractionationHydrogenation process

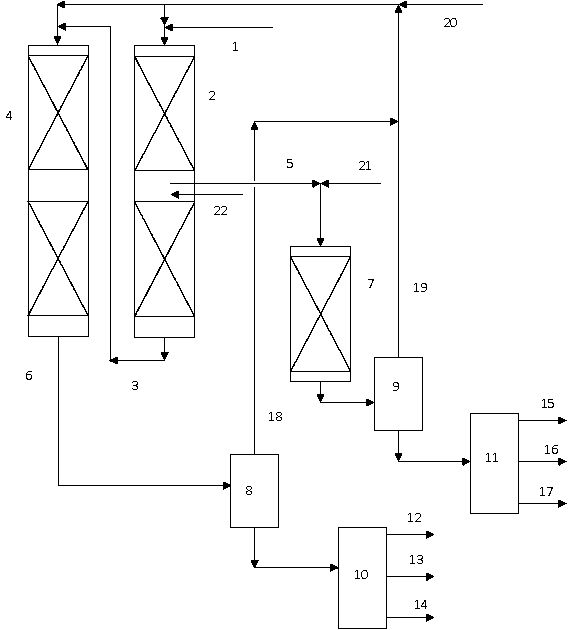

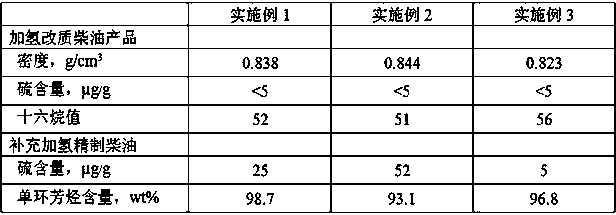

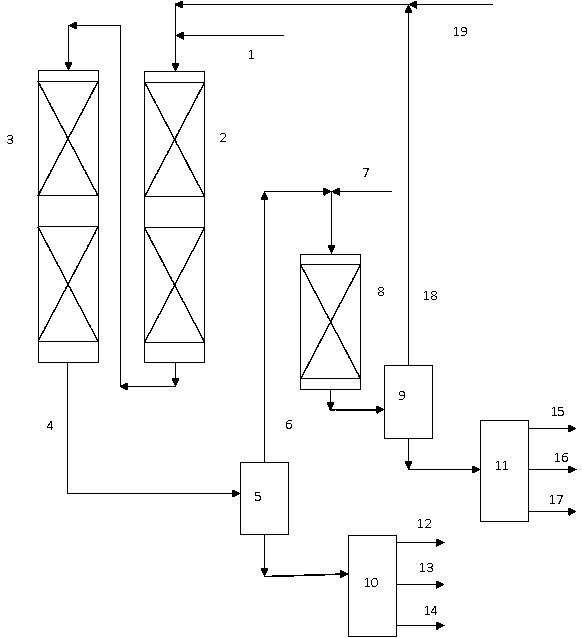

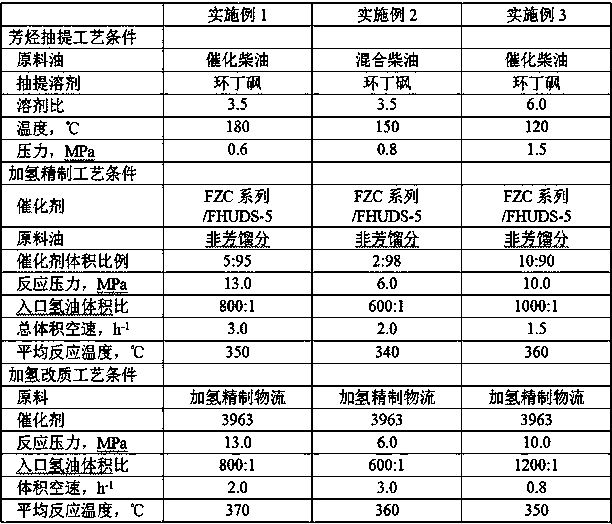

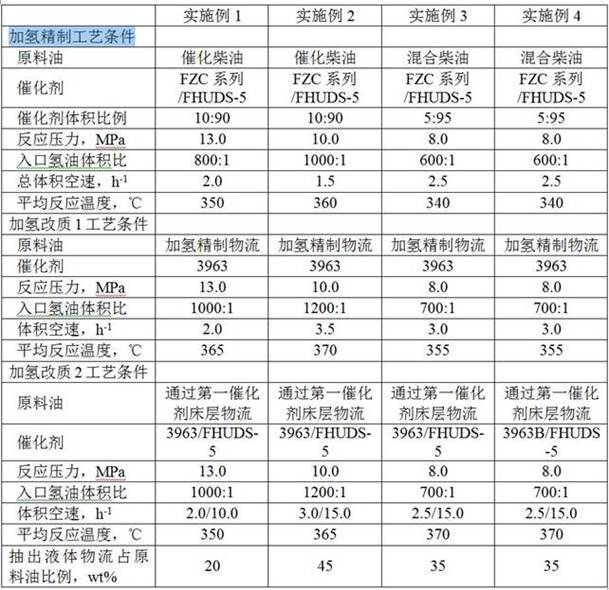

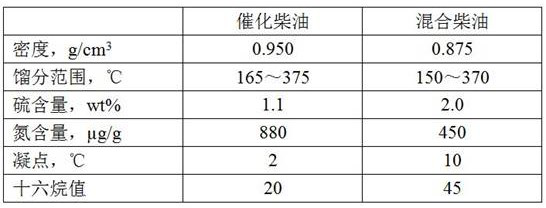

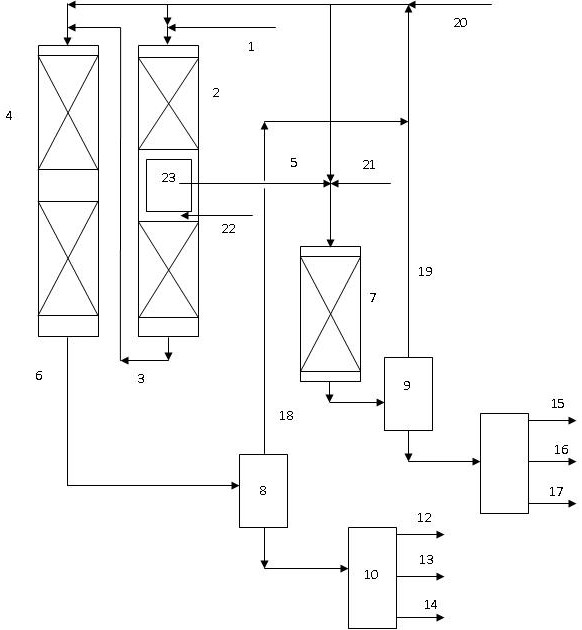

The invention discloses an inferior diesel oil hydro-upgrading and hydrofining combined process. A diesel oil raw material is firstly fractionated into a light fraction and a heavy fraction; the lightfraction is subjected to aromatic hydrocarbon extraction to obtain a light aromatic hydrocarbon fraction and a light non-aromatic hydrocarbon fraction; the heavy fraction enters a hydrofining reactor, and the material passing through a first hydrofining catalyst bed layer is divided into two streams; one material stream is extracted out of the hydrofining reactor and mixed with the light aromaticfraction, and the mixture enters a hydrofinishing reactor for hydrofinishing reaction; the other material stream is mixed with the light non-aromatic fraction and then flows downwards through a hydrofining catalyst bed layer at the lower part; the hydrofined material flow enters a hydro-upgrading reactor; and an obtained hydro-upgrading reaction material and an obtained hydrofinishing reaction material are respectively subjected to gas-liquid separation and fractionation to obtain high-quality diesel oil products and a high-quality FCC feed material. The invention provides the hydrogenation combined process for simultaneously producing more than two kinds of diesel fractions with different purposes on one set of hydrogenation process equipment for the first time.

Owner:CHINA PETROLEUM & CHEM CORP +1

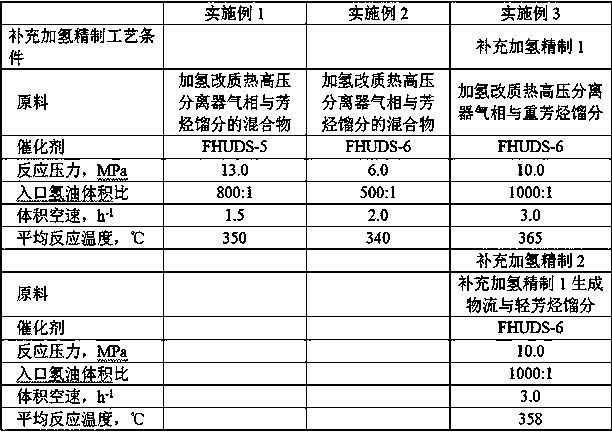

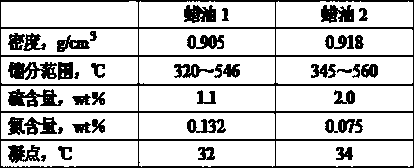

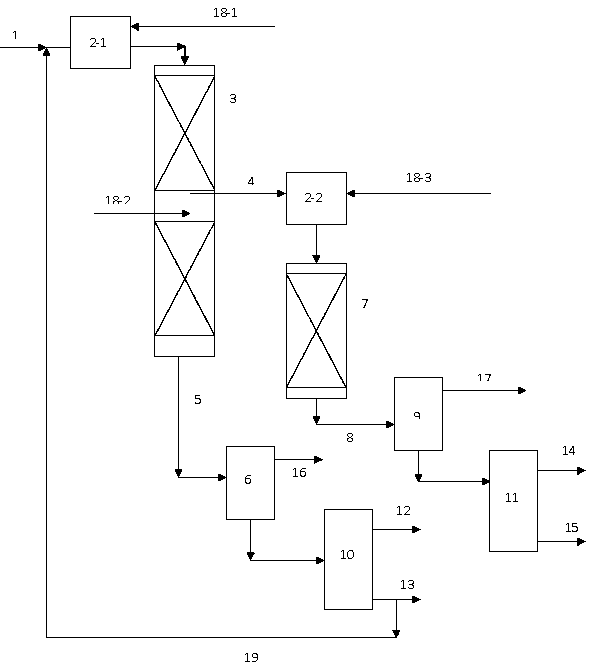

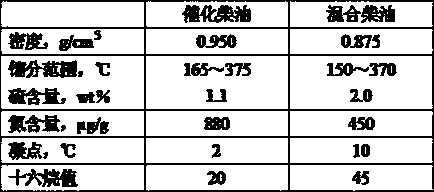

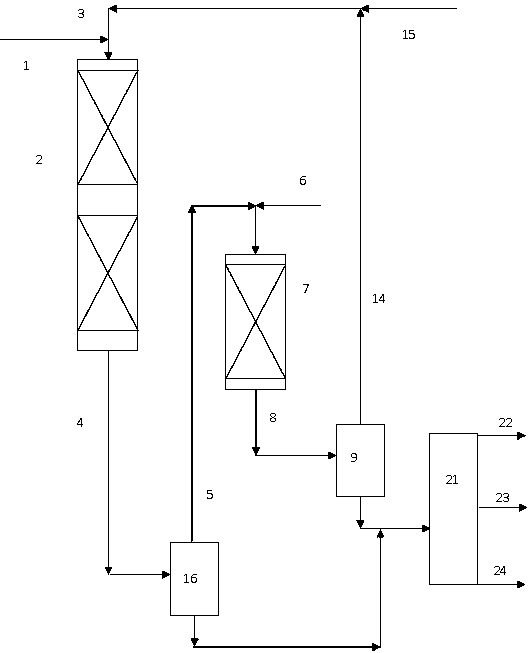

Inferior diesel oil hydro-upgrading and hydrofining combined method

ActiveCN109988650AFlexible production methodsEfficient removalTreatment with hydrotreatment processesGas phaseFractionation

The invention discloses an inferior diesel oil hydro-upgrading and hydrofining combined method. A diesel oil raw material is firstly subjected to aromatic hydrocarbon extraction to obtain an aromatichydrocarbon fraction and a non-aromatic fraction; the non-aromatic fraction enters a hydro-upgrading reaction zone under hydro-upgrading conditions, hydro-upgrading materials passing through a hydro-refining catalyst bed layer and a hydro-upgrading catalyst bed layer enters a hot high-pressure separator for obtaining of a gas phase and a liquid phase, and the liquid phase is subjected to separation and fractionation, so that high-quality naphtha and high-quality diesel oil products are obtained; and the gas phase of the hot high-pressure separator is mixed with the aromatic hydrocarbon fraction, the formed mixture enters a supplementary hydrofining reaction zone under hydrofining process conditions, and a supplementary hydrofining material flow obtained by a hydrofining catalyst bed layeris continuously subjected to gas-liquid separation and fractionation, so that a high-quality FCC feed is obtained. According to the invention, firstly the hydrogenation combined method for simultaneously producing two or more diesel fractions with different meshes by one set of hydrogenation process device is provided, heat carried by a part of hydrogenation modification materials can be fully utilized, and the effective utilization of energy is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

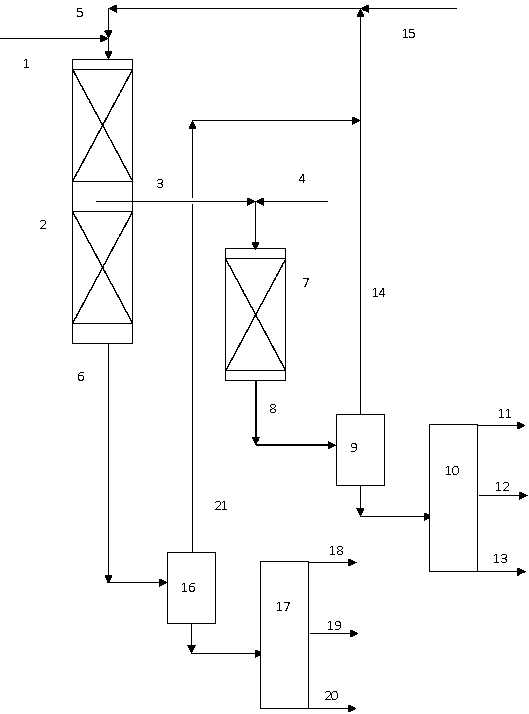

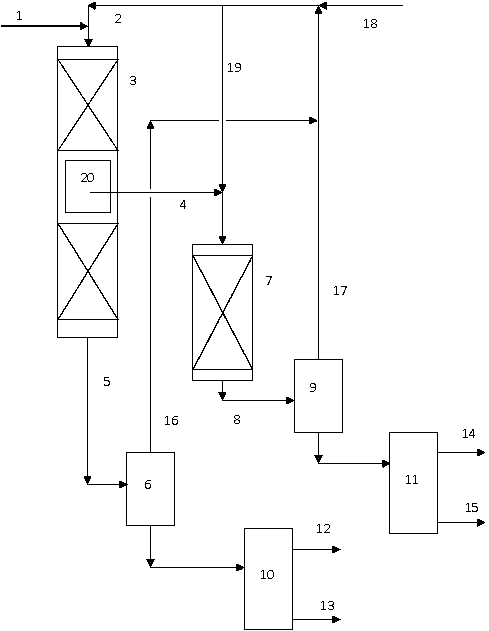

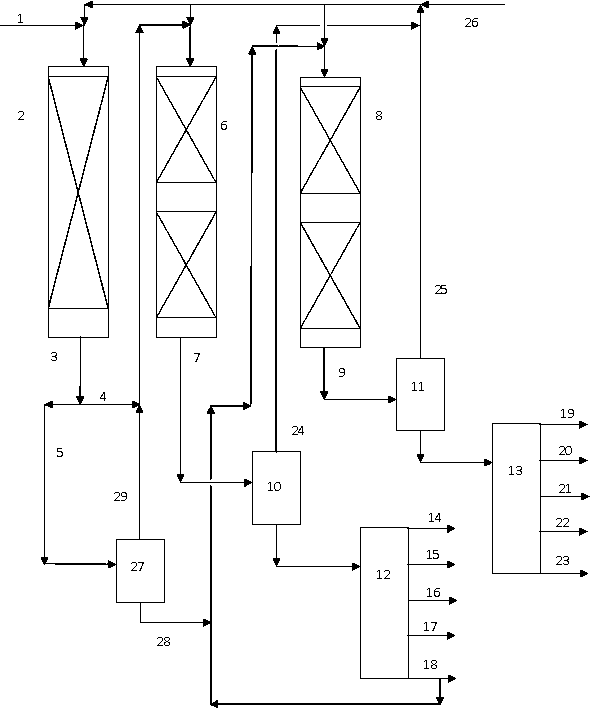

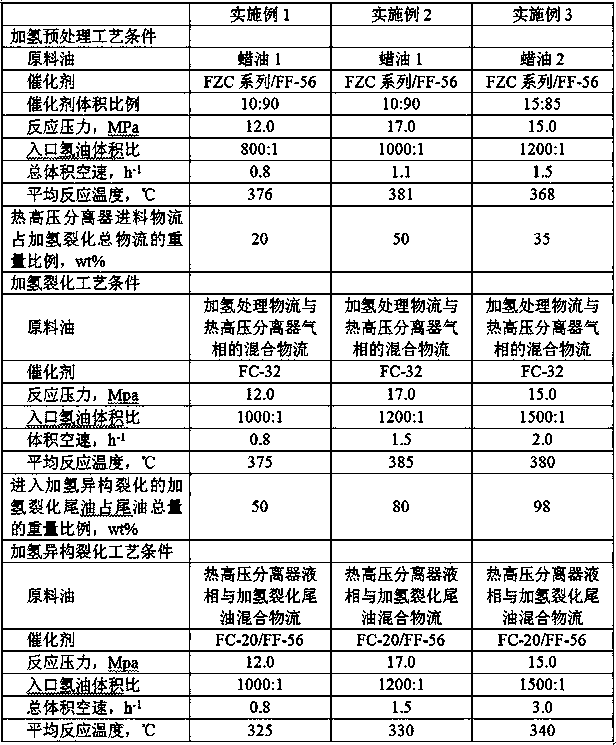

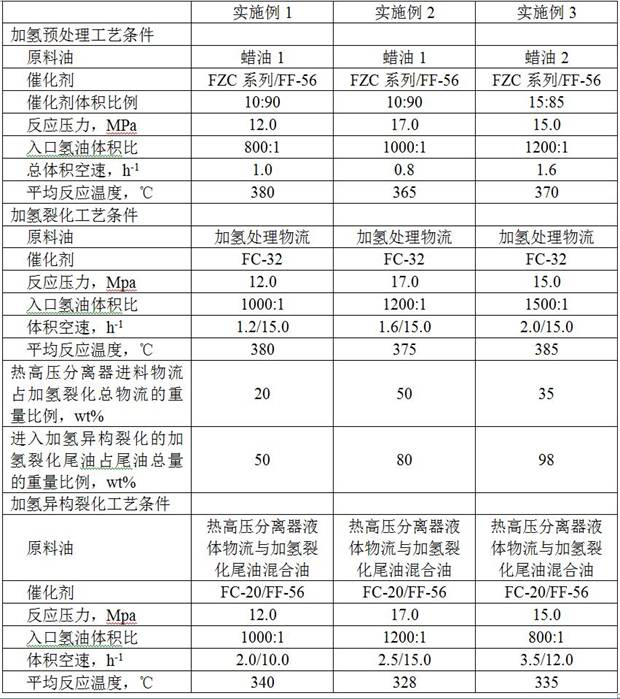

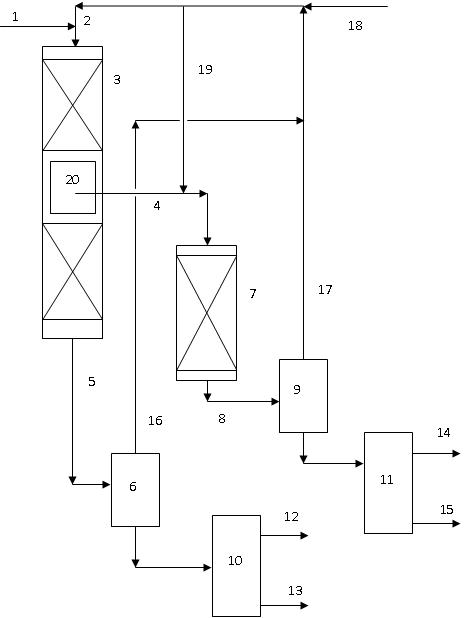

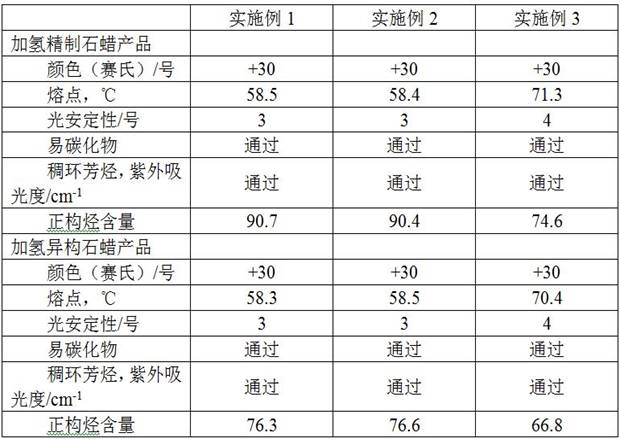

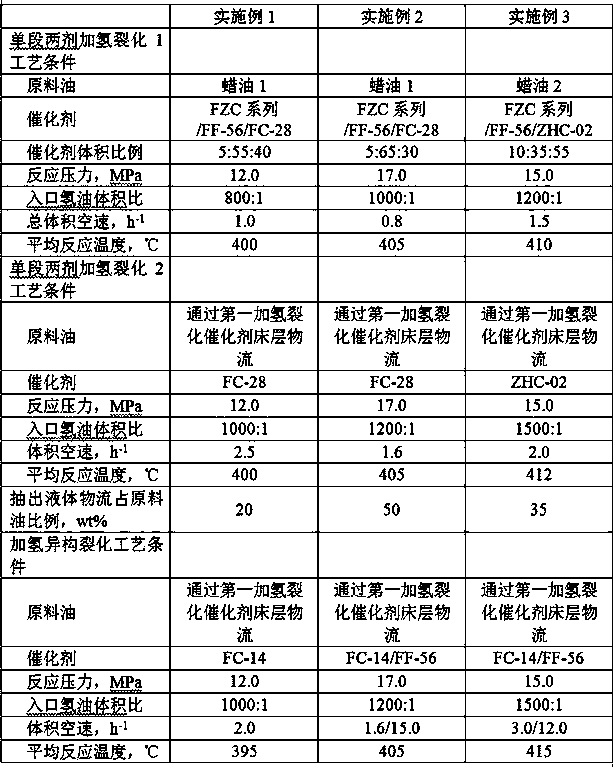

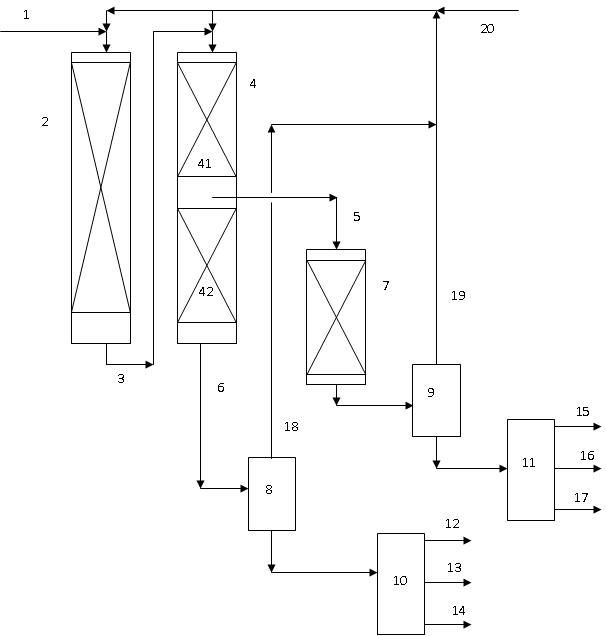

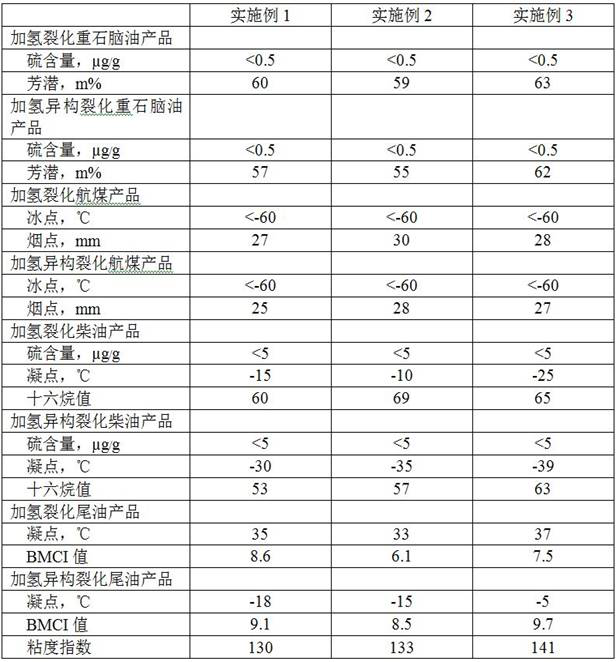

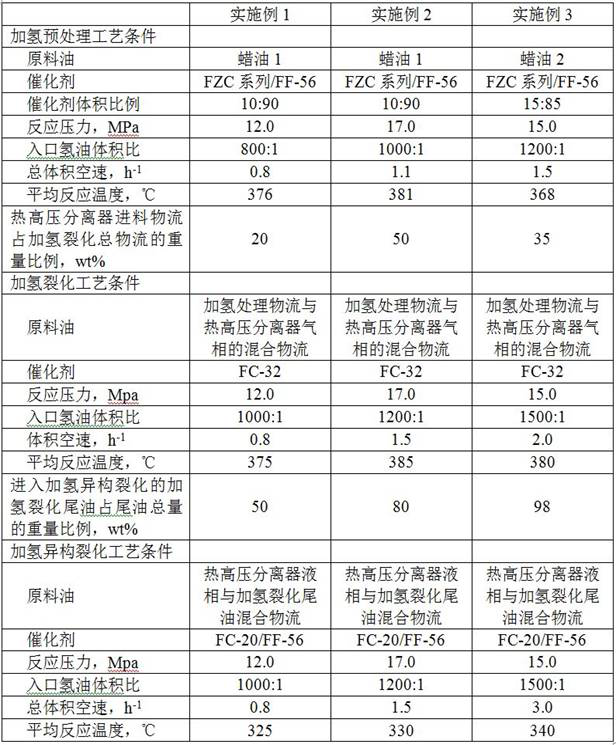

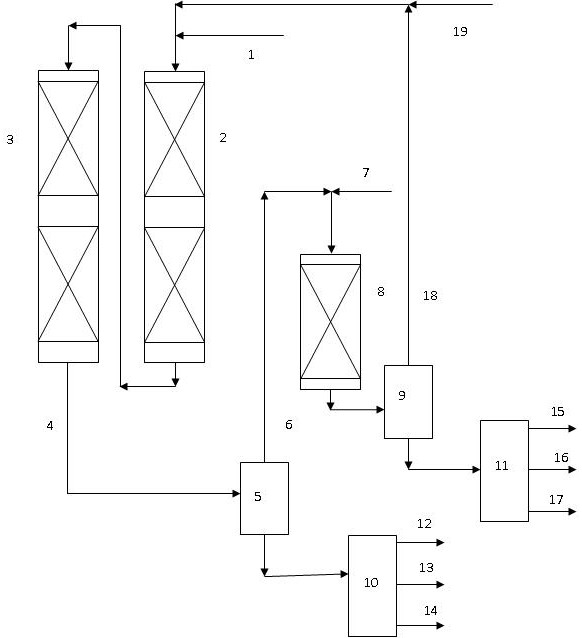

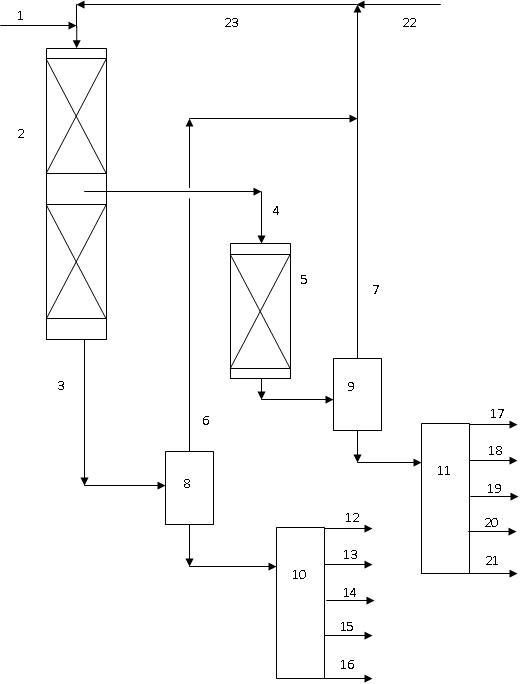

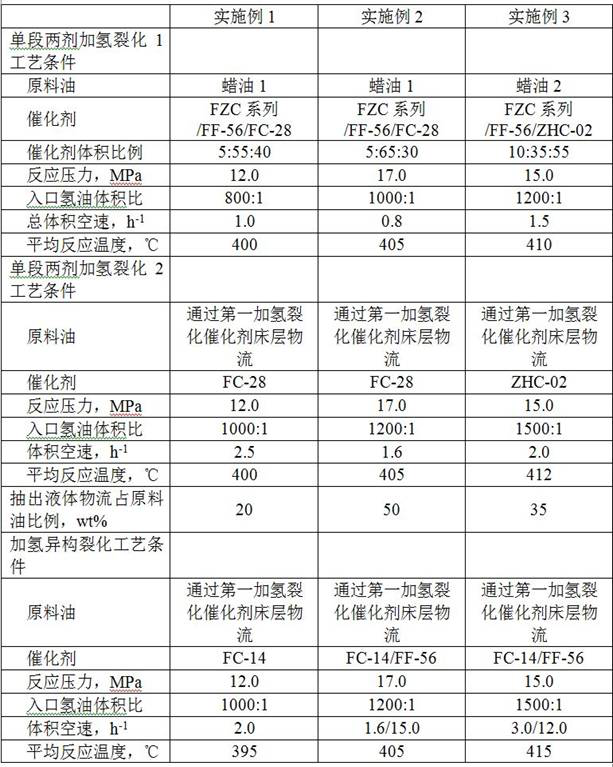

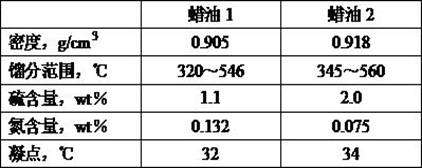

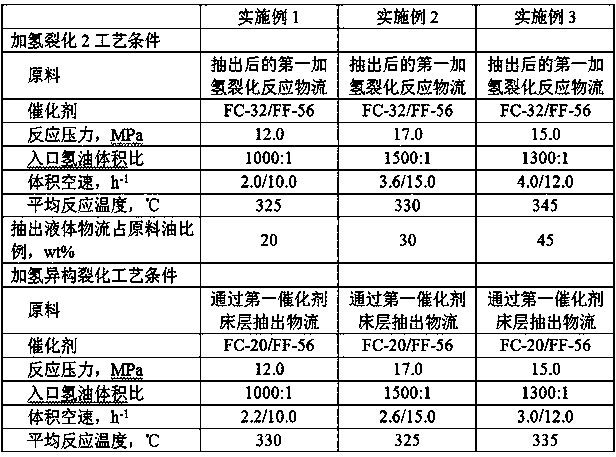

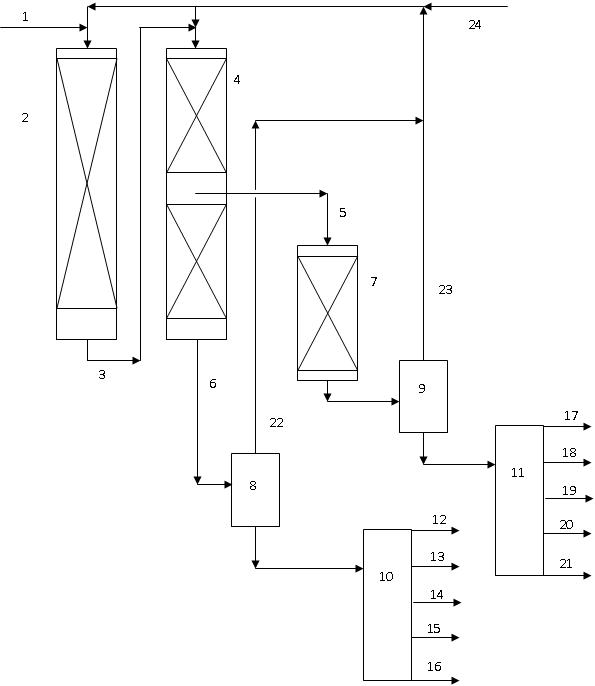

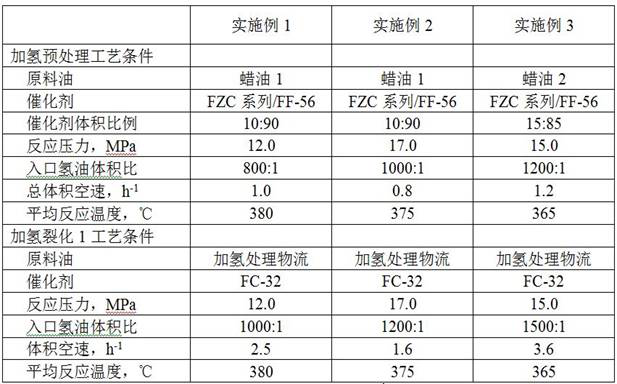

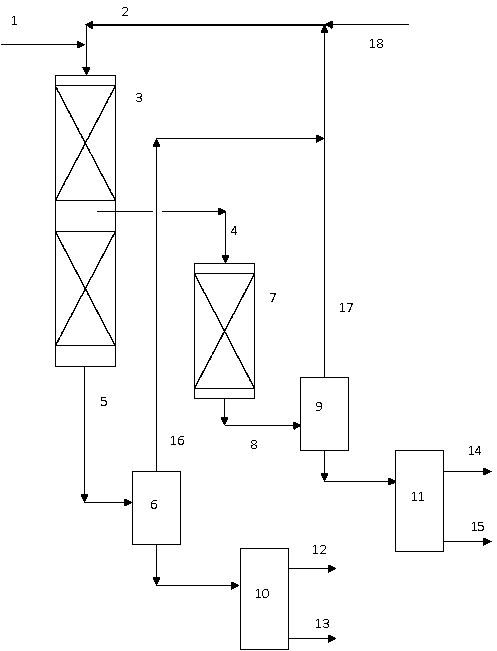

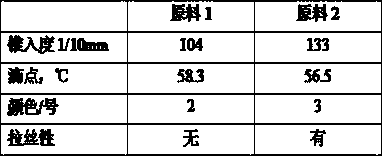

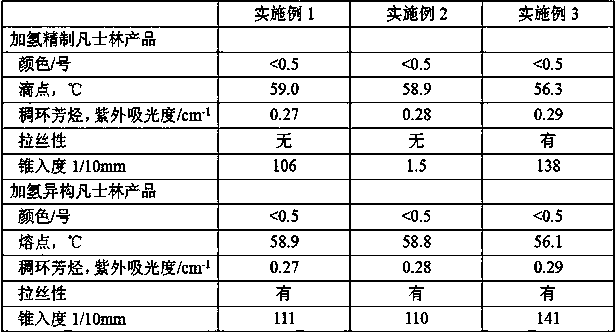

Flexible reverse-sequence hydrocracking process

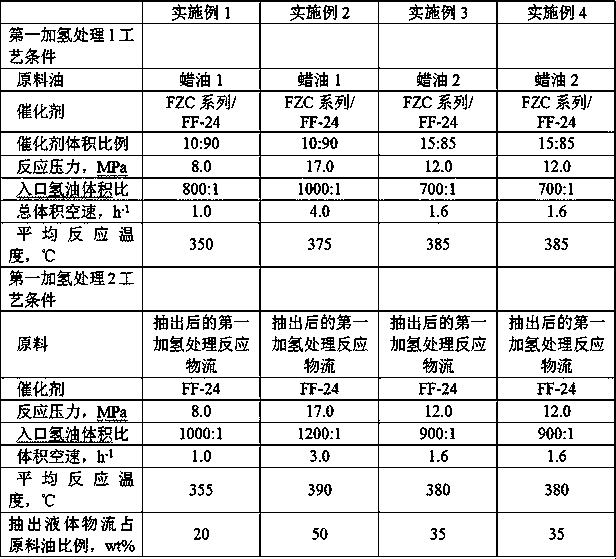

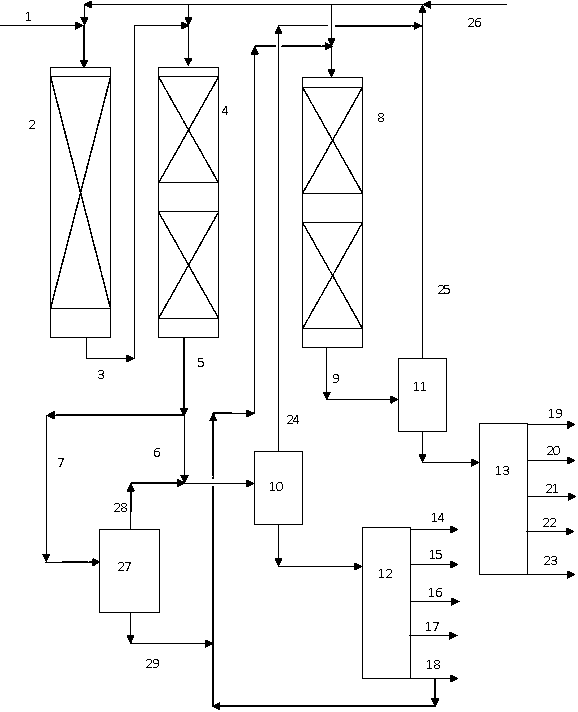

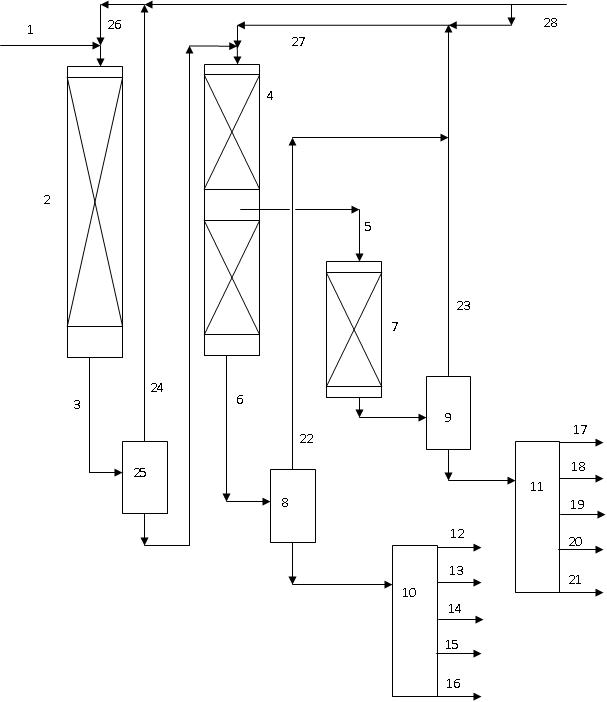

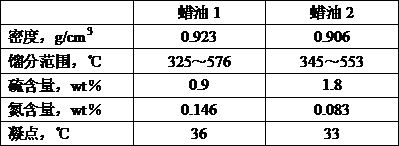

ActiveCN109988623AEffective distributionFlexible productionTreatment with hydrotreatment processesHydrocarbon oils treatment productsWaxChemistry

The invention discloses a flexible reverse-sequence hydrocracking process. The process comprises the following steps: mixing wax oil raw oil with a hydrocracked material; carrying out hydrogenation pretreatment; carrying out separation fractionation on the hydrogenation pretreated material flow to obtain gas, distillate oil and tail oil; carrying out hydrocracking pretreatment on the obtained tailoil, allowing the tail oil to pass through a first hydrocracking catalyst bed layer in a hydrocracking reactor to obtain a material, and dividing the obtained material into two streams; separating one material stream in a separator, extracting the obtained liquid phase out of the hydrocracking reactor, and subjecting the liquid phase to an isomerization cracking reaction in a hydroisomerization cracking reactor; allowing the other material stream to flow downward to pass through a second hydrocracking catalyst bed layer; and carrying out gas-liquid separation and fractionation on a hydroisomerization cracking reaction product to obtain hydroisomerization cracked naphtha, aviation kerosene, diesel oil and tail oil products. The invention provides the hydrocracking process for simultaneously producing more than two different-specification light naphtha, heavy naphtha, aviation kerosene, diesel oil and tail oil products on a set of hydrogenation process equipment.

Owner:CHINA PETROLEUM & CHEM CORP +1

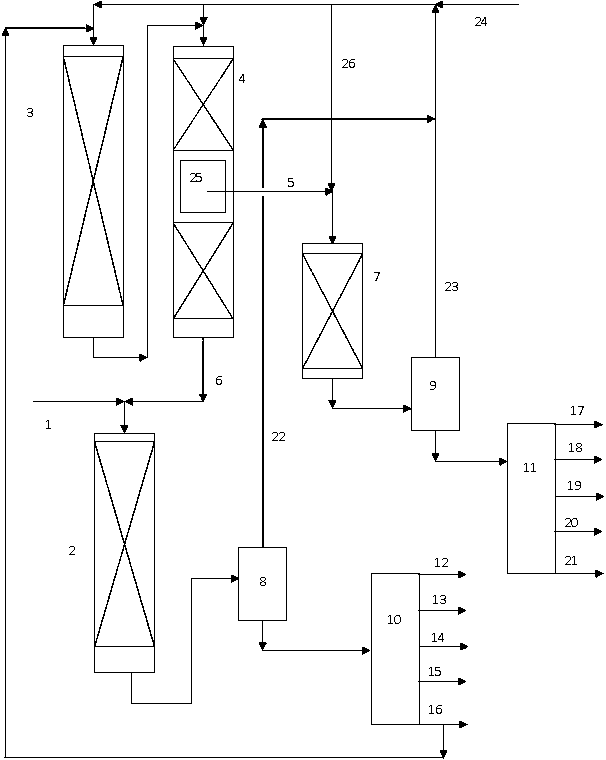

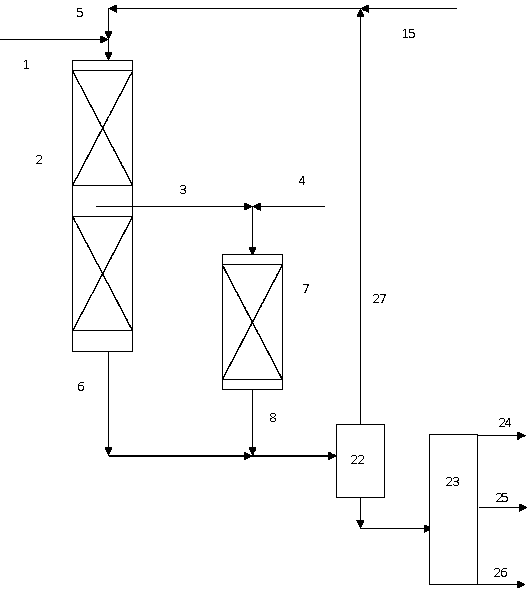

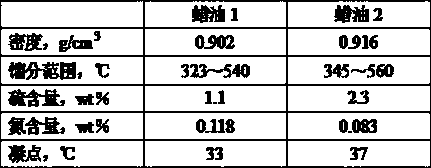

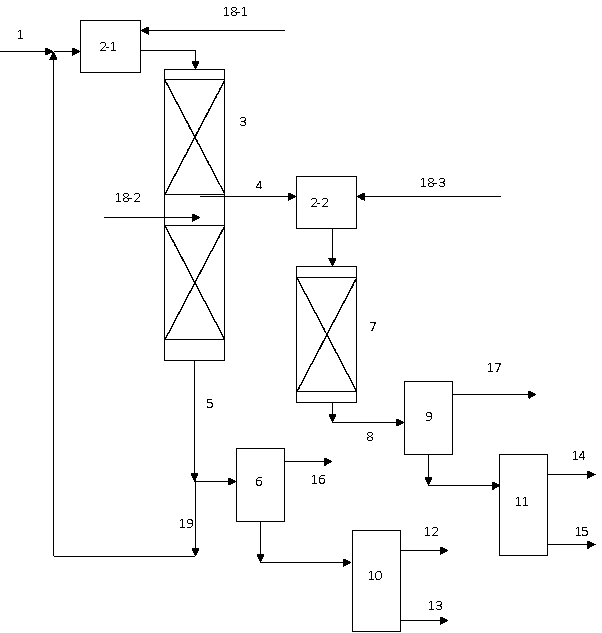

An inferior diesel oil hydro-upgrading and hydrofining combined process

ActiveCN109988643AFlexible production methodsFlexible productionTreatment with hydrotreatment processesHydrogenation processFractionation

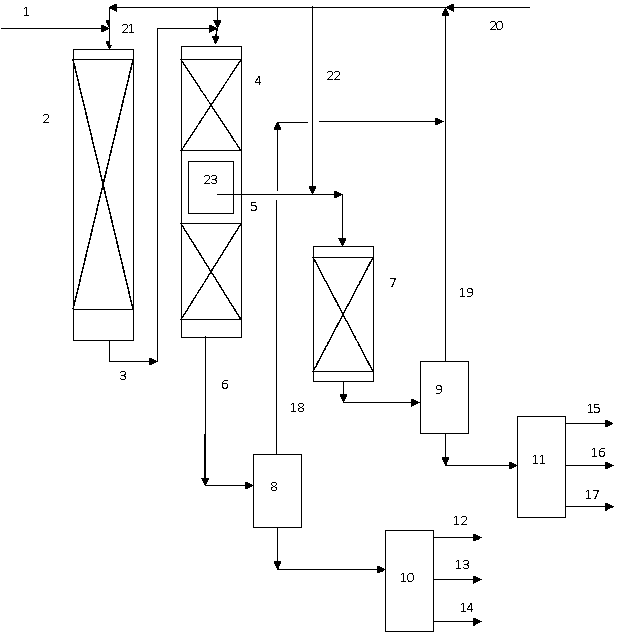

The invention discloses an inferior diesel oil hydro-upgrading and hydrofining combined process. A diesel oil raw material is fractionated to obtain a light fraction and a heavy fraction; the light fraction is subjected to extraction with aromatic hydrocarbon to obtain a light aromatic hydrocarbon fraction and a light non-aromatic hydrocarbon fraction; the heavy fraction enters a hydrofining reactor, and the material passing through a first hydrofining catalyst bed layer is divided into two streams; one material stream enters a separator, and the obtained liquid is extracted out of the hydrofining reactor and enters a hydro-finishing reactor together with the light aromatic hydrocarbon fraction for a hydro-finishing reaction; the other material stream is mixed with the light non-aromatic fraction and then flows downwards through a second hydrofining catalyst bed layer; a hydrofined material flow enters a hydro-upgrading reactor; and a hydro-upgrading reaction product and a hydro-finishing reaction product are respectively subjected to gas-liquid separation and fractionation to obtain high-quality diesel oil products and high-quality FCC feed materials. The invention provides the hydrogenation combined process for simultaneously producing more than two kinds of diesel fractions with different purposes on a set of hydrogenation process equipment.

Owner:CHINA PETROLEUM & CHEM CORP +1

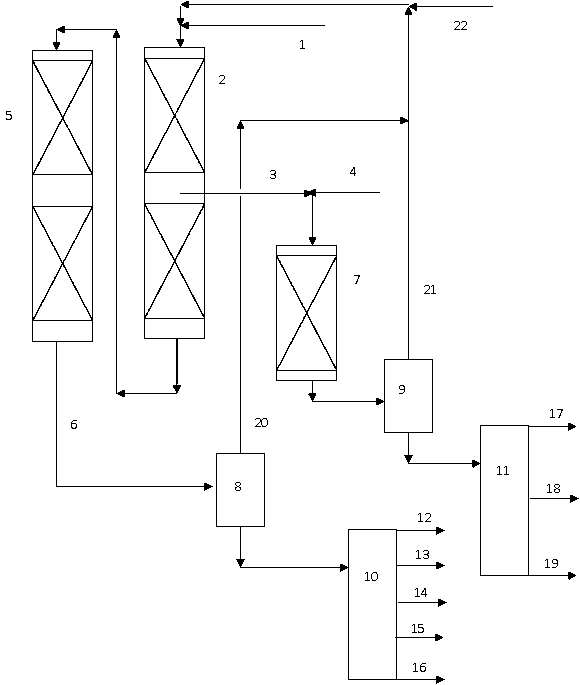

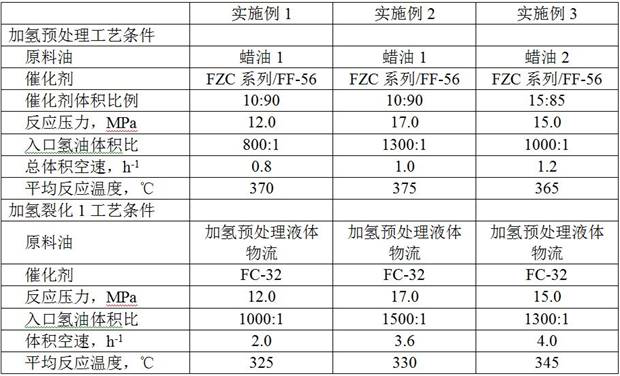

A hydrocracking process for flexibly producing diesel oil

ActiveCN109988648ALower freezing pointHigh viscosity indexTreatment with hydrotreatment processesHydrocarbon oils treatment productsWaxChemistry

The invention discloses a hydrocracking process for flexibly producing diesel oil. A wax oil raw material is subjected to hydrogenation pretreatment and then enters a hydrocracking reactor, and a hydrocracked material passing through a hydrocracking catalyst bed layer is divided into two streams; one stream of the hydrocracked material is subjected to gas-liquid separation and fractionation to obtain naphtha, aviation kerosene, diesel oil and tail oil; and the other stream of the hydrocracked material is mixed with a part or all of hydrocracking tail oil, and the mixture is fed into a hydrogenation isomerization cracking reactor and subjected to isomerization cracking; and a hydrogenation isomerization cracking product is subjected to gas-liquid separation and fractionation to obtain naphtha, aviation kerosene, diesel oil and tail oil. The invention provides the process for simultaneously producing more than two types of aviation kerosene, diesel oil and tail oil products with different specifications on one set of hydrogenation process equipment, especially diesel oil products with different condensation points, heat carried by a part of cracked materials can be fully utilized, and coupling operation of the hydrocracking reactor and the hydrogenation isomerization cracking reactor can be realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

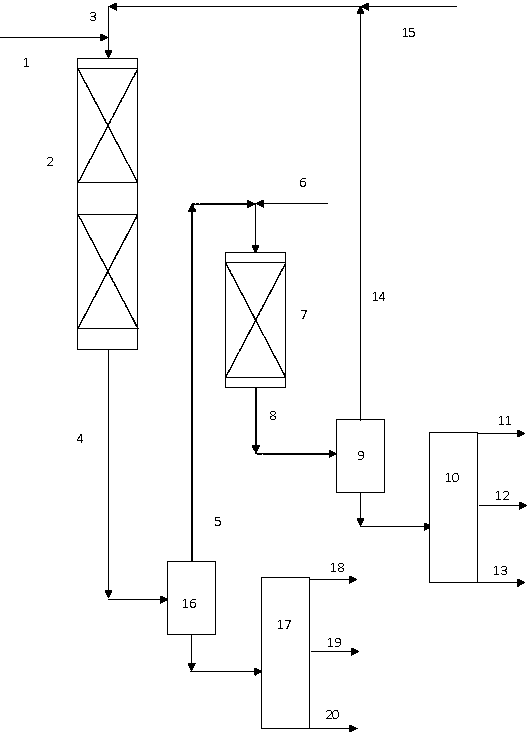

A flexible wax oil hydrotreatment process

ActiveCN109988615AEffective distributionHigh aromatic contentTreatment with hydrotreatment processesHydrocarbon oils treatment productsWaxNaphtha

The invention discloses a flexible wax oil hydrotreatment process. A wax oil raw material and hydrogen are mixed and then enter a first hydrotreatment reactor, and the material passing through an upper hydrotreatment catalyst bed layer is divided into two streams; one material stream is extracted out of a first hydrotreatment reactor from the middle of the bed layer and mixed with LCO, and the mixture is fed into a second hydrotreatment reactor and subjected to a hydrogenation reaction; the other material stream flows downwards through a hydrotreatment catalyst bed layer at the lower part; andan obtained first hydrotreatment reaction material and an obtained second hydrotreatment reaction material are subjected to gas-liquid separation and fractionation to obtain naphtha, diesel oil, hydrogenation heavy fractions and the like. The invention provides the flexible hydrotreatment process for flexibly processing different raw oil materials on a set of hydrogenation equipment and producinghigh-quality catalytic cracking raw materials, which can make full use of heat carried by part of a first hydrotreatment material and can realize coupling operation of a first hydrotreatment reactorand a second hydrotreatment reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

A flexible hydrocracking process for producing lubricant base oil

ActiveCN109988620AFlexible Hydrocracking ProcessFlexible productionTreatment with hydrotreatment processesHydrocarbon oils treatment productsIsomerizationGas phase

The invention discloses a flexible hydrocracking process for producing lubricant base oil. A material obtained after a wax oil raw material is subjected to hydrogenation pretreatment is divided into two parts; a part of the material is separated by a hot high-pressure separator to obtain a liquid phase, and the liquid phase is mixed with hydrogen and then passes through a hydrocracking catalyst bed layer containing a Y-type molecular sieve; the other part of the material is mixed with a gas phase obtained by hot high-pressure separation and hydrocracking tail oil and then passes through a hydroisomerization cracking catalyst bed layer containing an isomerization cracking type molecular sieve; a hydrocracking reaction product and a hydroisomerization cracking reaction product are subjectedto gas-liquid separation and fractionation separately to obtain distillate oil and tail oil products with different specifications; and the hydrocracking tail oil is partially or completely circulatedinto the isomerization cracking reactor. The process provided by the invention can be used for simultaneously producing more than two kinds of naphtha, aviation kerosene, diesel oil and tail oil products with different specifications on one set of hydrogenation process equipment, especially producing high-quality lubricant base oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

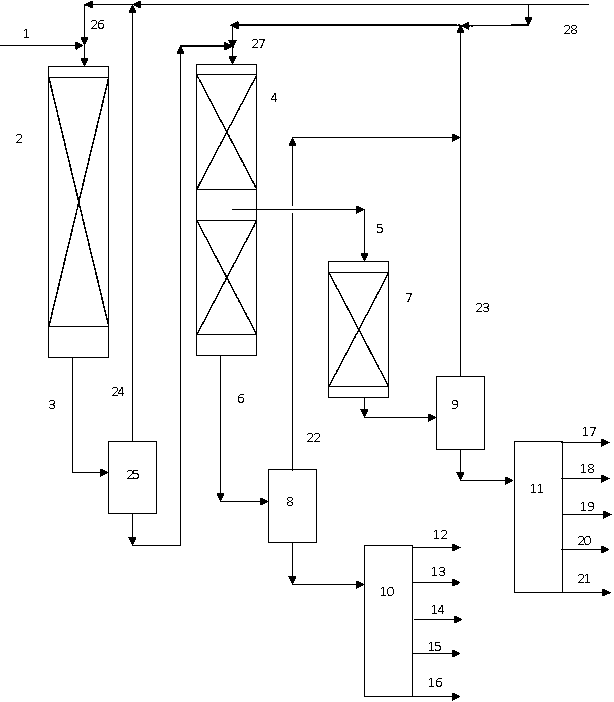

Hydrotreating and hydrocracking combined process

ActiveCN109988635AEffective distributionControl the depth of hydrogenationTreatment with hydrotreatment processesHydrocarbon oils treatment productsWaxNaphtha

The invention discloses a hydrotreatment and hydrocracking combined process. A wax oil raw material passes through a first hydrogenation pretreatment catalyst bed layer, and the obtained material is divided into two streams; one material stream is pumped out of a hydrogenation pretreatment reactor from the middle of the bed layer and mixed with LCO, the mixture passes through a hydrogenation reactor, and the hydrogenated material is subjected to gas-liquid separation and fractionation to obtain a catalytic cracking raw material; and the other material stream passes through a second hydrogenation pretreatment catalyst bed layer, the hydrogenation pretreatment stream passes through a hydrocracking catalyst bed layer to be subjected to a hydrocracking reaction, and the obtained hydrocracked material is subjected to gas-liquid separation and fractionation to obtain hydrocracking products such as naphtha, aviation kerosene, diesel oil and tail oil. The invention provides the hydrogenation combined process for simultaneously producing a hydrocracking light product and a catalytic cracking raw material on one set of hydrogenation process equipment for the first time, heat carried by the hydrogenation pretreatment material can be fully utilized, and coupling operation of the hydrogenation pretreatment reactor and the hydrogenation reactor is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

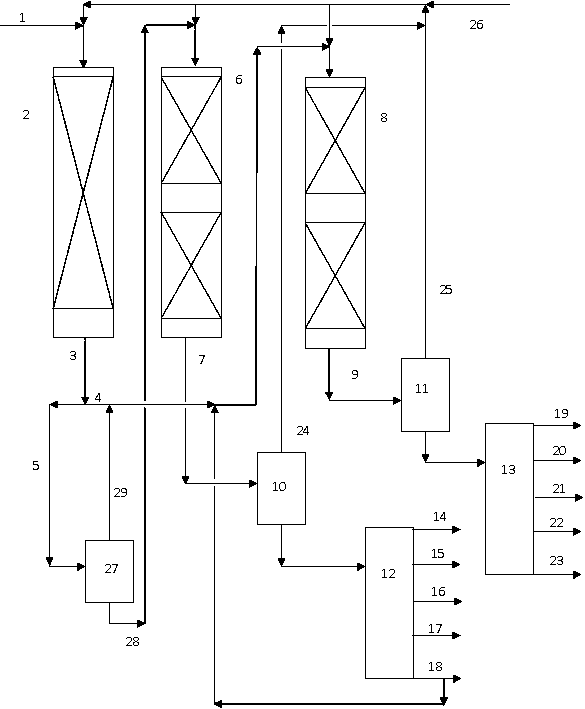

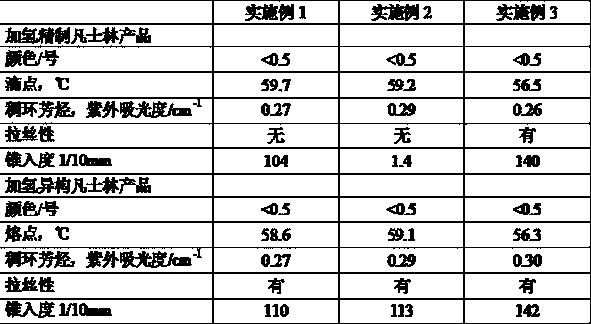

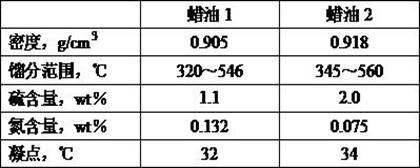

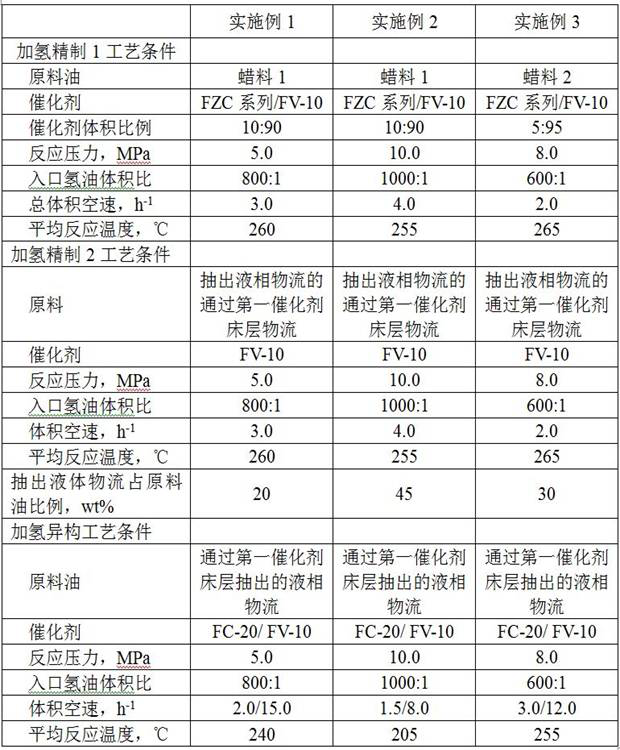

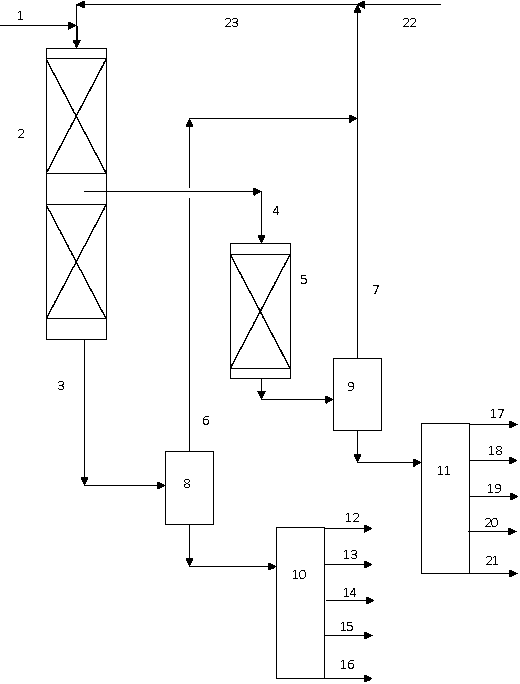

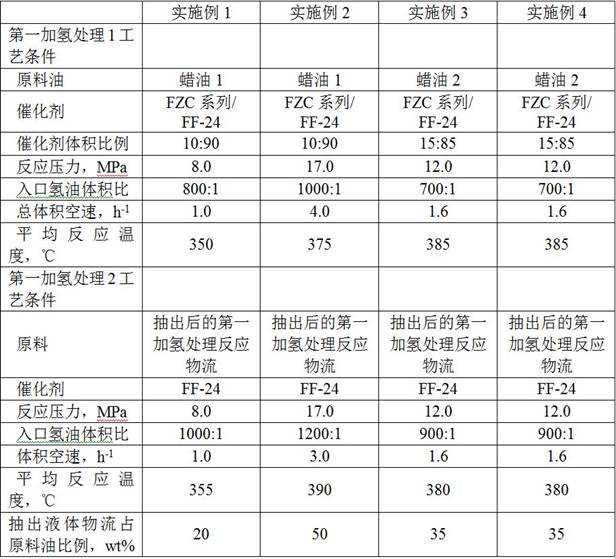

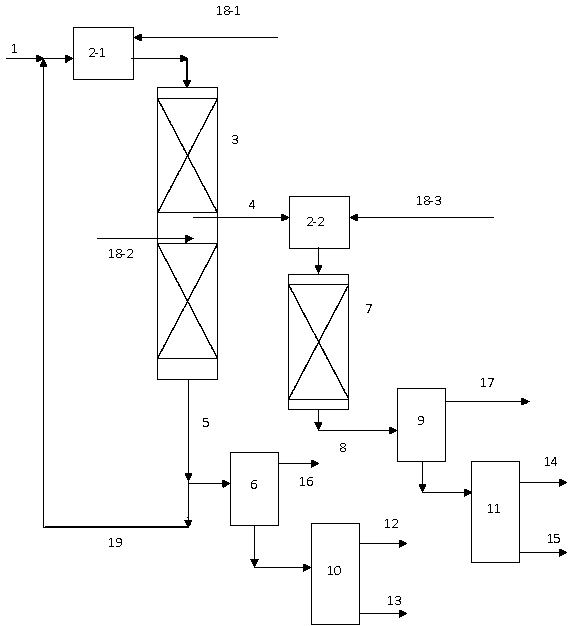

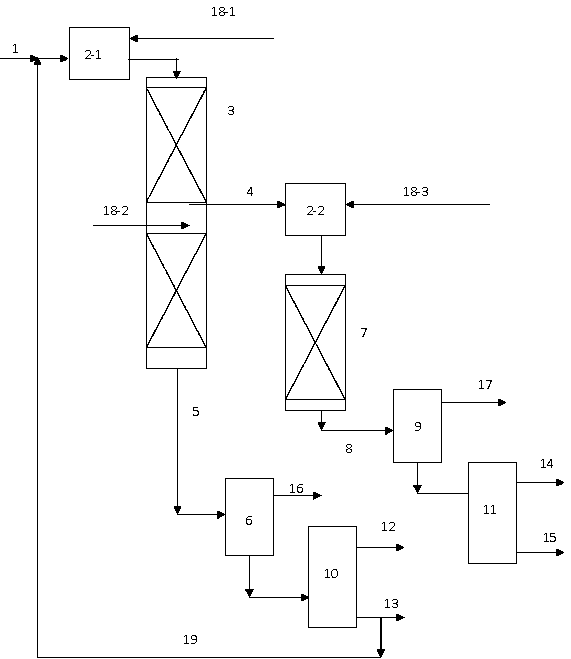

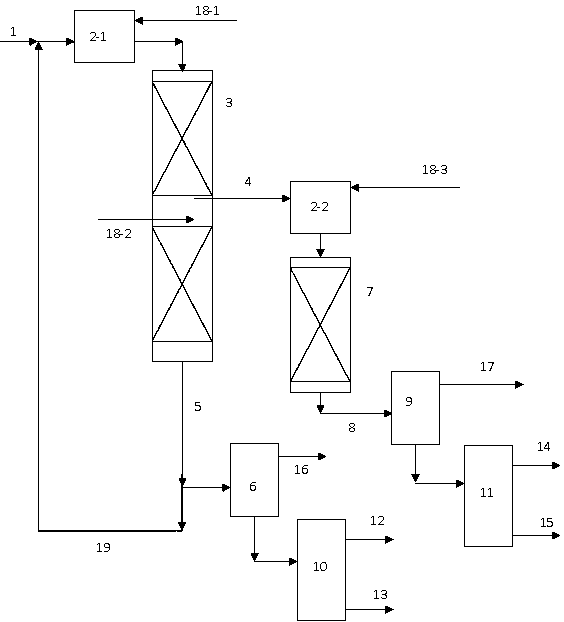

Flexible paraffin liquid phase hydrogenation process

ActiveCN109988608AEffective distributionFlexible productionPetroleum wax refiningTreatment with hydrotreatment processesParaffin waxIsomerization

The invention discloses a flexible paraffin liquid phase hydrogenation process. A paraffin raw material and circulating oil enter a liquid-phase hydrofining reactor under a liquid-phase hydrogenationcondition; the material passing through an upper hydrofining catalyst bed layer is divided into two streams; one material stream is extracted out of the liquid-phase hydrofining reactor from the middle of the bed layer, and fed into a liquid-phase hydroisomerization reactor for isomerization reaction; the other material stream continues flowing downward to pass through a lower hydrofining catalystbed layer; and an obtained hydrofining reaction material and an obtained hydroisomerization reaction material are subjected to gas-liquid separation and fractionation separately to obtain paraffin products with different specifications. The invention provides the hydrogenation process for simultaneously producing more than two paraffin products with different specifications on one set of liquid-phase hydrogenation process equipment for the first time, heat carried by a part of hydrofined materials can be fully utilized, and coupling operation of the liquid-phase hydrofining reactor and the liquid-phase hydroisomerization reactor is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flexible vaseline hydrogenation process

ActiveCN109988597AEffective distributionFlexible productionHydrocarbon oils treatmentIsomerizationVapor–liquid separator

The invention discloses a flexible vaseline hydrogenation process. A vaseline raw material enters a hydrofining reactor, and the material passing through an upper hydrofining catalyst bed layer is divided into two streams; one material stream is separated by a gas-liquid separator arranged in the middle of the bed layer, and the obtained liquid is extracted out of the hydrofining reactor and mixedwith hydrogen and then enters a hydroisomerization reactor to be subjected to an isomerization reaction; the other material stream is a mixture stream of gas in the reactor and a residual liquid after extraction, and the mixture stream flows downwards through a hydrofining catalyst bed layer at the lower part; and an obtained hydrofining reaction material and an obtained hydroisomerization reaction material are respectively subjected to gas-liquid separation and fractionation to obtain vaseline products with different specifications. The invention provides the hydrogenation process for simultaneously producing more than two vaseline products with different specifications on a set of hydrogenation process equipment for the first time, heat carried by part of hydrofined materials can be fully utilized, and coupling operation of the hydrofining reactor and the hydroisomerization reactor can be realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

A flexible hydrocracking method for producing lubricant base oil

ActiveCN109988642AHigh normal hydrocarbon contentHigh viscosity indexTreatment with hydrotreatment processesHydrocarbon oils treatment productsIsomerizationGas phase

The invention discloses a flexible hydrocracking method for producing lubricant base oil. The method includes dividing a wax oil raw material subjected to hydrogenation pretreatment into two parts; separating one part of the material by a hot high-pressure separator to obtain a gas phase and a liquid phase; mixing the other part of the material with the gas phase obtained by hot high-pressure separation and circulating hydrogen, and allowing the mixture to pass through a hydrocracking catalyst bed layer containing a Y-type molecular sieve; mixing the liquid phase obtained by hot high-pressureseparation with hydrocracking tail oil and circulating hydrogen, and allowing the mixture to pass through a hydroisomerization cracking catalyst bed layer containing an isomerization cracking type molecular sieve; respectively carrying out gas-liquid separation and fractionation on a hydrocracking reaction product and a hydroisomerization cracking reaction product to obtain distillate oil and tailoil products with different specifications; and partially or completely circulating the hydrocracking tail oil to an isomerization cracking reactor. The invention provides the flexible hydrocrackingmethod for simultaneously producing more than two kinds of naphtha, aviation kerosene, diesel oil and tail oil products with different specifications on a set of hydrogenation process equipment for the first time, especially high-quality lubricant base oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking Process for Flexible Diesel Production

ActiveCN109988611BFlexible productionHigh content of saturated hydrocarbonsTreatment with hydrotreatment processesHydrocarbon oils treatment productsThermodynamicsNaphtha

The invention discloses a hydrocracking process for flexibly producing diesel oil. After the wax oil raw material is pretreated by hydrogenation, it enters the hydrocracking reactor, and the obtained hydrocracking material is divided into two streams, one of which enters the hot high-pressure separator to separate the gas phase and liquid phase; the one that does not enter the high-pressure separator The hydrocracked material is mixed with the gas phase separated by the hot high-pressure separator for gas-liquid separation and fractionation to obtain hydrocracked naphtha, jet fuel, diesel oil and tail oil; the liquid phase separated by the hot high-pressure separator and / or After all the hydrocracking tail oil is mixed, continue to mix with hydrogen for hydroisomerization cracking reaction, and the hydroisomerization cracking material undergoes gas-liquid separation and fractionation to obtain hydroisomerization cracking naphtha, jet fuel, diesel oil and tail oil . The invention provides for the first time a hydrocracking process for simultaneously producing more than two types of jet fuel, diesel oil and tail oil products of different specifications, especially diesel oil with different freezing points, on a set of hydrogenation process equipment.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flexible paraffin hydrogenation process

ActiveCN109988637BEffective distributionFlexible productionPetroleum wax refiningTreatment with hydrotreatment processesParaffin waxPtru catalyst

The invention discloses a flexible paraffin hydrogenation process. The paraffin wax raw material enters the hydrofining reactor, and the material after passing through the upper hydrofining catalyst bed is divided into two streams; one stream of material passes through the gas-liquid separator installed in the middle of the bed, and the separated liquid is drawn out of the refining reactor and mixed with hydrogen into the The hydroisomerization reactor carries out the isomerization reaction; the other material is the gas in the reactor and the remaining liquid mixture flow after extraction, and the mixture flow continues to flow down through the lower hydrofinishing catalyst bed; the resulting hydrofinishing reaction The material and the hydroisomerization reaction material are subjected to gas-liquid separation and fractionation respectively to obtain paraffin products of different specifications. The present invention provides a hydrogenation process for the simultaneous production of two or more paraffin products of different specifications on a set of hydrogenation process equipment for the first time, which can make full use of the heat carried by part of the hydrogenation refining material to realize the hydrogenation refining reactor and hydrogenation process. Coupling operation of hydroisomerization reactors.

Owner:CHINA PETROLEUM & CHEM CORP +1

A flexible single-stage two-catalyst hydrocracking process

ActiveCN109988618AFlexible productionLowering the freezing pointTreatment with hydrotreatment processesHydrocarbon oils treatment productsPtru catalystIsomerization

The invention discloses a flexible single-stage two-catalyst hydrocracking process. A wax oil raw material and hydrogen are mixed and then enter a single-stage two-catalyst hydrocracking reactor, andthe material passing through an upper hydrogenation pretreatment catalyst bed layer and a single-stage hydrocracking catalyst bed layer is divided into two streams; one material stream is extracted out of the single-stage reactor from the middle of the bed layers, enters a hydroisomerization cracking reactor and subjected to isomerization cracking reaction; the other material stream flows downwards through a single-stage hydrocracking catalyst bed layer at the lower part; and a single-stage hydrocracking reaction product and a hydroisomerization cracking reaction product are respectively separated and fractionated to obtain distillate oil and tail oil products with different specifications. The invention provides the process for simultaneously producing more than two types of light naphtha, heavy naphtha, aviation kerosene, diesel oil and tail oil products with different specifications on a set of hydrogenation process equipment. In the process, heat carried by part of cracked materials can be fully utilized, and coupling operation of the single-stage two-catalyst hydrocracking reactor and the hydroisomerization cracking reactor is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

A Flexible Diesel Hydrogenation Upgrading and Depressing Process

ActiveCN109988622BEffective distributionFlexible productionTreatment with hydrotreatment processesHydrocarbon oils treatment productsThermodynamicsPtru catalyst

The invention discloses a process for hydrogenation, upgrading and pour point reduction of flexible diesel oil. After the diesel raw material is hydrogenated and refined, it enters the hydrogenation upgrading reactor, and the material passing through the upper hydrogenation upgrading catalyst bed is divided into two strands; one strand of material is extracted from the upgrading reactor through the middle of the bed, and enters the hydrogenation downgrading reactor. The decondensation reaction is carried out in the condensing reactor; another stream of material continues to flow downward through the lower hydrogenation modification catalyst bed; specifications of diesel products. The present invention provides for the first time a hydrogenation upgrading process for simultaneous production of two or more diesel products of different specifications on a set of hydrogenation process equipment, which can make full use of the heat carried by part of the upgrading materials to realize the hydrogenation decondensation reactor Coupling operation with hydro-upgrading reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

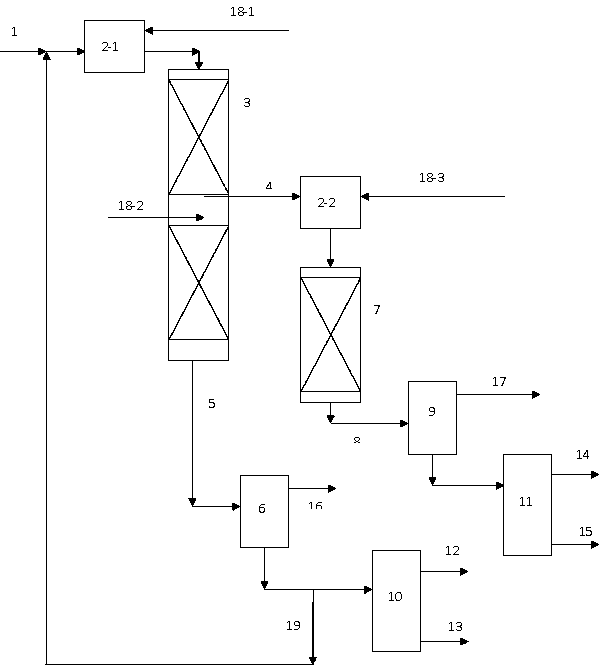

Inferior diesel oil hydro-upgrading and hydro-refining combined process

ActiveCN109988643BFlexible production methodsFlexible productionTreatment with hydrotreatment processesPtru catalystHydrogenation reaction

The invention discloses a combination process of hydrogenation upgrading and hydrogenation refining of low-quality diesel oil. The diesel raw material is fractionated to obtain light and heavy fractions, and the light fraction is extracted by aromatics to obtain light aromatic fractions and light non-aromatic fractions; the heavy fraction enters the hydrotreating reactor, and the material after passing through the first hydrotreating catalyst bed is divided into two One stream of material enters the separator, and the obtained liquid is drawn out of the hydrofinishing reactor and the light aromatic fraction enters the supplementary hydrofinishing reactor for supplementary hydrogenation reaction; the other stream of material is mixed with the light non-aromatic fraction and continues to flow downward through the first The second hydrorefining catalyst bed, the hydrorefining stream continues to enter the hydrorefining reactor, and the hydrorefining reaction material and the supplementary hydrorefining reaction material are subjected to gas-liquid separation and fractionation respectively to obtain high-quality diesel products and high-quality FCC feedstocks. material. The invention provides a combined hydrogenation process for simultaneously producing two or more diesel oil fractions with different purposes on a set of hydrogenation process devices.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking process for flexibly producing diesel oil

ActiveCN109988611ALower freezing pointIncreased isoparaffin contentTreatment with hydrotreatment processesHydrocarbon oils treatment productsWaxNaphtha

The invention discloses a hydrocracking process for flexibly producing diesel oil. A wax oil raw material is subjected to hydrogenation pretreatment and then enters a hydrocracking reactor; the obtained hydrocracked material is divided into two streams; one stream enters a hot high-pressure separator to be separated to obtain a gas phase and a liquid phase; one hydrocracked material stream which does not enter the high-pressure separator is mixed with the gas phase separated by the hot high-pressure separator, and the mixture is subjected to gas-liquid separation and fractionation to obtain hydrocracked naphtha, aviation kerosene, diesel oil and tail oil; the liquid phase obtained through separation by the hot high-pressure separator is mixed with a part or all of the hydrocracking tail oil and then mixed with hydrogen, the mixture is subjected to a hydroisomerization cracking reaction, and an obtained hydroisomerization cracking material is subjected to gas-liquid separation and fractionation to obtain hydroisomerization cracked naphtha, aviation kerosene, diesel oil and tail oil. The invention provides, for the first time, the hydrocracking process for simultaneously producing more than two aviation kerosene, diesel oil and tail oil products with different specifications on one set of hydrogenation process equipment, particularly diesel oil products with different condensation points.

Owner:CHINA PETROLEUM & CHEM CORP +1

A flexible hydrocracking process for the production of lube base stocks

ActiveCN109988642BFlexible productionFang QiangaoTreatment with hydrotreatment processesHydrocarbon oils treatment productsMolecular sievePtru catalyst

The invention discloses a flexible hydrocracking method for producing lubricating oil base oil. The wax oil raw material after hydrogenation pretreatment is divided into two parts; one part of the material is separated by a hot high-pressure separator to obtain a gas phase and a liquid phase, and the other part of the material is mixed with a hot high-fraction gas phase and circulating hydrogen and passed through a hydrogenation system containing a Y-type molecular sieve. Cracking catalyst bed; after the hot high-resolution liquid phase is mixed with hydrocracking tail oil and circulating hydrogen, it passes through the hydroisomerization cracking catalyst bed containing isomerization cracking type molecular sieve; hydrocracking reaction product and hydroisomerization cracking The reaction products are subjected to gas-liquid separation and fractionation respectively to obtain distillate oil and tail oil of different specifications, and part or all of the hydrocracking tail oil is recycled into the isomerization cracking reactor. The present invention provides for the first time a flexible hydrocracking method for simultaneously producing two or more different specifications of naphtha, aviation fuel, diesel oil, and tail oil products, especially high-quality lubricating oil base oil, on a set of hydrogenation process equipment.

Owner:CHINA PETROLEUM & CHEM CORP +1

Combination method of hydro-upgrading and hydro-refining of low-quality diesel oil

ActiveCN109988650BFlexible production methodsEfficient removalTreatment with hydrotreatment processesNaphthaPtru catalyst

The invention discloses a combined method of hydrogenation upgrading and hydrogenation refining of low-quality diesel oil. The diesel feedstock is firstly extracted with aromatics to obtain aromatic fractions and non-aromatic fractions; the non-aromatic fractions enter the hydro-upgrading reaction zone under hydro-upgrading conditions, and are separated by hydrofining catalyst bed and hydro-upgrading catalyst bed. The hydrogenated and upgraded material enters the hot high-pressure separator to obtain gas phase and liquid phase. The liquid phase is separated and fractionated to obtain high-quality naphtha and high-quality diesel products; In the hydrofinishing reaction zone, the supplementary hydrofinishing stream obtained through the hydrofinishing catalyst bed continues to undergo gas-liquid separation and fractionation to obtain high-quality FCC feed. The present invention provides for the first time a combined hydrogenation method for simultaneously producing two or more diesel fractions with different purposes on a set of hydrogenation process equipment, which can make full use of the heat carried by partial hydrogenation-upgrading materials and realize effective utilization of energy.

Owner:CHINA PETROLEUM & CHEM CORP +1

A flexible single-stage two-agent hydrocracking process

ActiveCN109988618BFlexible productionLowering the freezing pointTreatment with hydrotreatment processesHydrocarbon oils treatment productsThermodynamicsNaphtha

The invention discloses a flexible single-stage two-agent hydrocracking process. The wax oil raw material is mixed with hydrogen and enters the single-stage two-component hydrocracking reactor. The material after passing through the upper hydrogenation pretreatment catalyst and the single-stage hydrocracking catalyst bed is divided into two streams; one stream of material is drawn out from the middle of the bed. stage reactor, enters the hydroisomerization cracking reactor for isomerization cracking reaction; another stream of material continues to flow down through the lower single-stage hydrocracking catalyst bed; the single-stage hydrocracking reaction material and hydroisomerization cracking The reaction materials are separated and fractionated separately to obtain distillate oil and tail oil products of different specifications. The invention provides a single-stage two-dose hydrocracking process for simultaneously producing two or more different specifications of light naphtha, heavy naphtha, jet fuel, diesel oil, and tail oil products on a set of hydrogenation process equipment, which can fully Using the heat carried by part of the cracked material, the coupling operation of the single-stage two-component hydrocracking reactor and the hydroisomerization cracking reactor is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

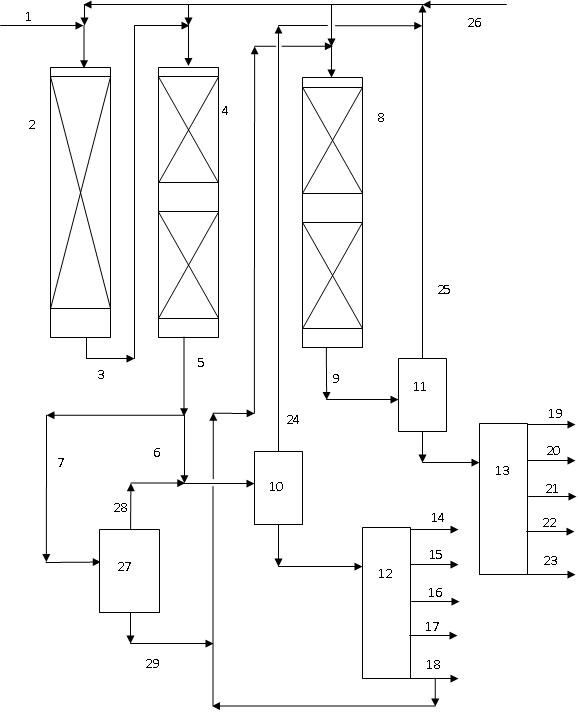

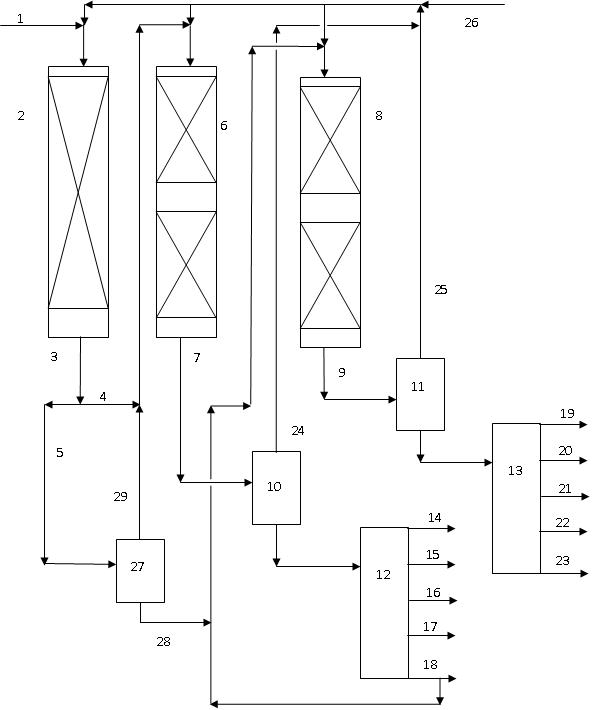

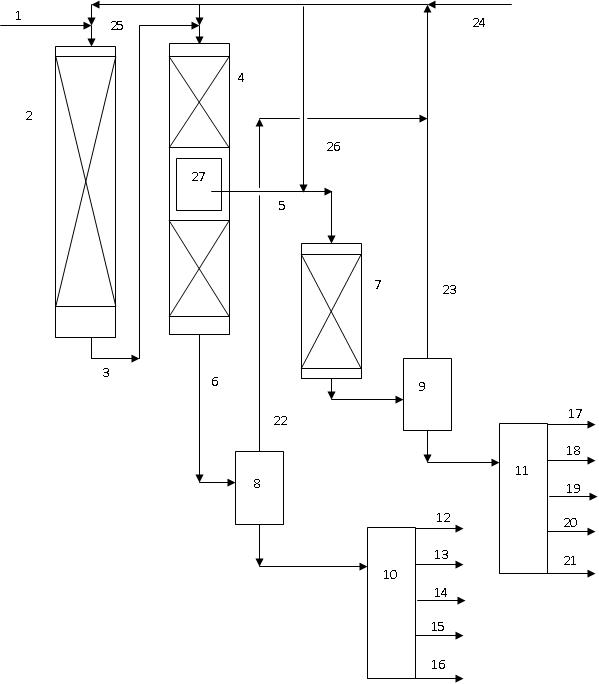

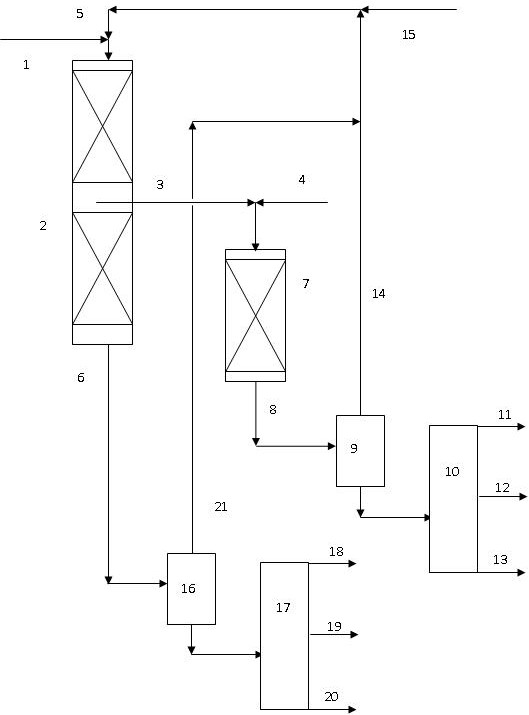

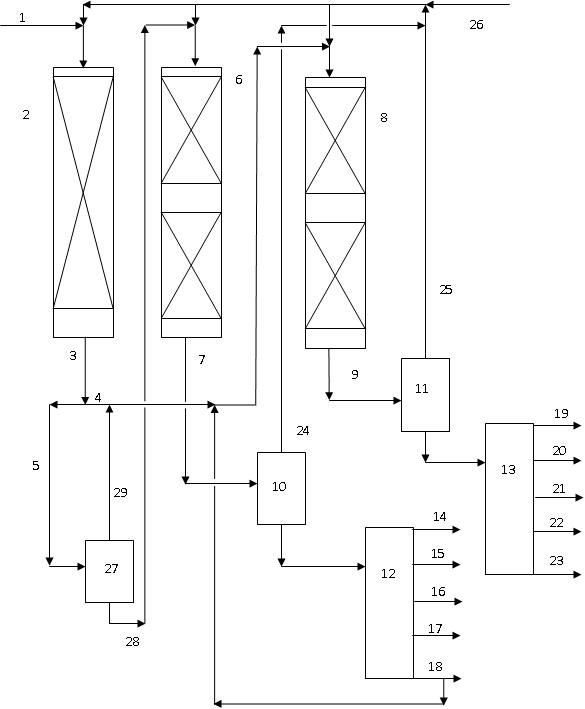

Flexible Hydrocracking Process

ActiveCN109988621BEffective distributionFlexible productionTreatment with hydrotreatment processesHydrocarbon oils treatment productsNaphthaPtru catalyst

The invention discloses a flexible hydrocracking process. After hydrogenation pretreatment, the wax oil raw material enters the hydrocracking reactor, and the material after passing through the first hydrocracking catalyst bed is divided into two streams; one stream of material is separated, and the obtained liquid is pumped out of the hydrocracking reactor and mixed with hydrogen Then enter the hydroisomerization cracking reactor for isomerization cracking reaction; another stream of material mixture continues to flow downward through the second hydrocracking catalyst bed; the obtained hydrocracking reaction product and hydroisomerization cracking reaction product respectively Carry out gas-liquid separation and fractionation to obtain naphtha, jet fuel, diesel and tail oil products of different specifications. The present invention provides for the first time a hydrocracking process for simultaneous production of two or more different specifications of light naphtha, heavy naphtha, jet fuel, diesel, and tail oil products on a set of hydrogenation process equipment, which can make full use of partial cracking The heat carried by the material realizes the coupled operation of the hydrocracking reactor and the hydroisomerization cracking reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flexible diesel oil hydro-upgrading process

ActiveCN109988612AEffective distributionFlexible productionTreatment with hydrotreatment processesHydrocarbon oils treatment productsProcess equipmentHydrogen

The invention discloses a flexible diesel oil hydro-upgrading process. The process comprises the following steps: after hydrofining a diesel oil raw material, feeding the diesel oil raw material intoa hydro-upgrading reactor; dividing the material passing through a first hydro-upgrading catalyst bed layer into two streams; separating one material stream to obtain liquid, pumping the liquid out ofthe hydro-upgrading reactor, mixing the liquid with hydrogen, and allowing the mixture to enter a hydroisomerization pour point depressing reactor for isomerization pour point depressing reaction; allowing the other material stream to continue flowing downward to pass through a second hydro-upgrading catalyst bed layer; and respectively carrying out gas-liquid separation and fractionation on an obtained hydro-upgrading reaction material and an obtained hydroisomerization pour point depression reaction material to obtain diesel oil products with different specifications. The invention providesthe hydro-upgrading process for simultaneously producing more than two diesel oil products with different specifications on one set of hydro-upgrading process equipment for the first time, heat carried by part of modified materials can be fully utilized, and coupling operation of the hydro-upgrading reactor and the hydroisomerization pour point depressing reactor is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

A flexible wax oil hydrotreating process

ActiveCN109988615BEffective distributionHigh aromatic contentTreatment with hydrotreatment processesHydrocarbon oils treatment productsNaphthaPtru catalyst

The invention discloses a flexible wax oil hydrogenation treatment process. The wax oil raw material is mixed with hydrogen and enters the first hydrotreating reactor, and the material passing through the upper hydrotreating catalyst bed is divided into two streams; one stream of material is extracted from the first hydrotreating reactor through the middle of the bed, and mixed with LCO mixed into the second hydrotreating reactor for hydrogenation reaction; another stream of material continues to flow down through the lower hydrotreating catalyst bed, and the obtained first hydrotreating reaction material and second hydrotreating reaction material undergo gas-liquid Separation and fractionation to obtain naphtha, diesel and hydrogenated heavy fractions. The invention provides a flexible hydrogenation treatment process for flexibly processing different raw material oils on a hydrogenation device to produce high-quality catalytic cracking raw materials, which can make full use of the heat carried by part of the first hydrogenation treatment materials to realize the first hydrogenation Coupling operation of the hydrotreating reactor and the second hydrotreating reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

Residual oil hydrotreatment and hydrofining combined process

ActiveCN109988634ABoost octaneReduce the difficulty of cracking reactionTreatment with hydrotreatment processesHydrocarbon oils treatment productsNaphthaGas phase

The invention discloses a residual oil hydrotreatment and hydrofining combined process. Residual oil raw materials and hydrogen are mixed and then enter a hydrotreating reactor; the material generatedby hydrotreating after passing through a graded hydrotreating catalyst bed layer enters a hydrotreating hot high-pressure separator to be separated; an obtained hot gas phase material flow is mixed with LCO, and the mixture is fed into a hydrofining reactor and subjected to a hydrofining reaction; a material generated by hydrofining is separated; and a liquid phase separated by a hydrotreating high-pressure separator and a liquid phase obtained by hydrofining high-pressure separation are fractionated to obtain naphtha, diesel oil, hydrogenated heavy fractions and the like. The invention provides the flexible hydrogenation process for producing high-quality catalytic cracking raw materials by processing different raw material oil materials on one set of combined hydrogenation process equipment.

Owner:CHINA PETROLEUM & CHEM CORP +1

A flexible two-stage hydrocracking process

ActiveCN109988626AEffective distributionFlexible productionTreatment with hydrotreatment processesHydrocarbon oils treatment productsWaxIsomerization

The invention discloses a flexible two-stage hydrocracking process. A wax oil raw material is subjected to hydrogenation pretreatment and then enters a separation system, an obtained liquid phase without impurities enters a hydrocracking reactor containing a reduction state hydrocracking catalyst, and an obtained first hydrocracked material is divided into two streams; one material stream is extracted out of the hydrocracking reactor through the middle of a bed layer and enters an isomerization cracking reactor containing a reduction state hydroisomerization cracking catalyst for reaction; theother material stream flows through a hydrocracking catalyst bed layer at the lower part; and an obtained hydrocracking reaction material and an obtained hydroisomerization cracking reaction materialare subjected to gas-liquid separation and fractionation separately to obtain distillate oil and tail oil products with different specifications. The invention provides the hydrocracking process forsimultaneously producing more than two distillate oil and tail oil products with different specifications on one set of hydrogenation equipment for the first time, heat carried by part of cracked materials can be fully utilized, and coupling operation of the hydrocracking reactor and the hydroisomerization cracking reactor can be realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

A flexible hydrocracking process

ActiveCN109988640BEffective distributionFlexible productionTreatment with hydrotreatment processesHydrocarbon oils treatment productsNaphthaPtru catalyst

The invention discloses a flexible hydrocracking process. After the wax oil raw material is pretreated by hydrogenation, it enters the hydrocracking reactor, and the material passing through the upper hydrocracking catalyst bed is divided into two strands; one strand of material is extracted from the hydrocracking reactor through the middle of the bed, and enters the hydrocracking reactor. The isomerization cracking reactor carries out the isomerization cracking reaction; another stream of material continues to flow downward through the lower hydrocracking catalyst bed; the obtained hydrocracking reaction material and hydroisomerization cracking reaction material are subjected to gas-liquid separation and fractionation respectively Get different specifications of naphtha, jet fuel, diesel and tail oil products. The present invention provides for the first time a hydrocracking process for simultaneously producing two or more different specifications of light naphtha, heavy naphtha, jet fuel, diesel oil, and tail oil products on a set of hydrogenation process equipment, which can make full use of partial cracking The heat carried by the material realizes the coupled operation of the hydrocracking reactor and the hydroisomerization cracking reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flexible vaseline hydrogenation process

ActiveCN109988619AEffective distributionFlexible productionTreatment with hydrotreatment processesIsomerizationStream flow

The invention discloses a flexible vaseline hydrogenation process. A vaseline raw material enters a hydrofining reactor, and the material passing through an upper hydrofining catalyst bed layer is divided into two streams; one material stream is extracted out of the hydrofining reactor through the middle of the bed layer and enters a hydroisomerization reactor for isomerization reaction; the othermaterial stream flows downwards through a hydrofining catalyst bed layer at the lower part; and an obtained hydrofining reaction material and an obtained hydroisomerization reaction material are subjected to gas-liquid separation and fractionation separately to obtain vaseline products with different specifications. The invention provides the hydrogenation process for simultaneously producing more than two vaseline products with different specifications on a set of hydrogenation process equipment for the first time, heat carried by part of hydrofined materials can be fully utilized, and coupling operation of the hydrofining reactor and the hydroisomerization reactor can be realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flexible two-stage hydrocracking process

ActiveCN109988607BEffective distributionFlexible productionTreatment with hydrotreatment processesHydrocarbon oils treatment productsNaphthaPtru catalyst

The invention discloses a combined process of hydrotreating and hydrocracking. The wax oil raw material passes through the first hydrogenation pretreatment catalyst bed, and the obtained material is divided into two streams; one stream of material is drawn out of the hydrogenation pretreatment reactor through the middle of the bed, and mixed with LCO to pass through the hydrotreatment reactor, and the hydrotreatment stream Carry out gas-liquid separation and fractional distillation to obtain catalytic cracking raw materials; another stream of material continues to pass through the second hydrogenation pretreatment catalyst bed, and the hydrogenation pretreatment stream passes through the hydrocracking catalyst bed for hydrocracking reaction, and the obtained hydrocracking reaction The material is subjected to gas-liquid separation and fractional distillation to obtain hydrocracking products such as naphtha, jet fuel, diesel oil and tail oil. The present invention provides for the first time a combined hydrogenation process for simultaneous production of hydrocracking light products and catalytic cracking raw materials on a set of hydrogenation process equipment, which can make full use of the heat carried by the hydrogenation pretreatment material to realize hydrogenation pretreatment Coupling operation of treatment reactor and hydrotreating reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

A flexible hydrocracking process for the production of lube base stocks

ActiveCN109988620BFlexible productionFang QiangaoTreatment with hydrotreatment processesHydrocarbon oils treatment productsMolecular sievePtru catalyst

The invention discloses a flexible hydrocracking process for producing lubricating oil base oil. The wax oil raw material after hydrogenation pretreatment is divided into two parts; one part of the material is separated by a hot high-pressure separator to obtain a liquid phase, and after being mixed with hydrogen, it passes through a hydrocracking catalyst bed containing Y-type molecular sieve; After the gas phase and hydrocracking tail oil are mixed, they pass through the hydroisomerization cracking catalyst bed containing isomerization cracking type molecular sieve; Standard distillate oil and tail oil; part or all of the hydrocracking tail oil is recycled into the isomerization cracking reactor. The process of the present invention can simultaneously produce more than two kinds of naphtha, aviation fuel, diesel oil and tail oil products of different specifications on a set of hydrogenation process equipment, especially high-quality lubricating oil base oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

A flexible vaseline liquid phase hydrogenation process

ActiveCN109988616AEffective distributionFlexible productionTreatment with hydrotreatment processesIsomerizationStream flow

The invention discloses a flexible vaseline liquid phase hydrogenation process. A vaseline raw material and circulating oil are mixed and enter a liquid-phase hydrofining reactor, and the material passing through an upper hydrofining catalyst bed layer is divided into two streams; one material stream is extracted out of the liquid-phase hydrofining reactor from the middle of the bed layer, entersa liquid-phase hydroisomerization reactor and is subjected to isomerization; the other material stream flows downwards through a hydrofining catalyst bed layer at the lower part; and an obtained hydrofining reaction material and an obtained hydroisomerization reaction material are subjected to gas-liquid separation and fractionation separately to obtain vaseline products with different specifications. The invention provides the liquid-phase hydrogenation process for simultaneously producing more than two types of vaseline products with different specifications on one set of hydrogenation process equipment for the first time, heat carried by part of hydrofined materials can be fully utilized, and coupling operation of the liquid-phase hydrofining reactor and the liquid-phase hydroisomerization reactor can be realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com