Inferior diesel oil hydro-upgrading and hydro-refining combined process

A hydrorefining and hydromodification technology, which is applied in the fields of hydrotreating process, petroleum industry, and hydrocarbon oil treatment, can solve the problems of unfavorable production of high-quality gasoline, effective control, harsh process conditions, and poor product flexibility, etc., to achieve production The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

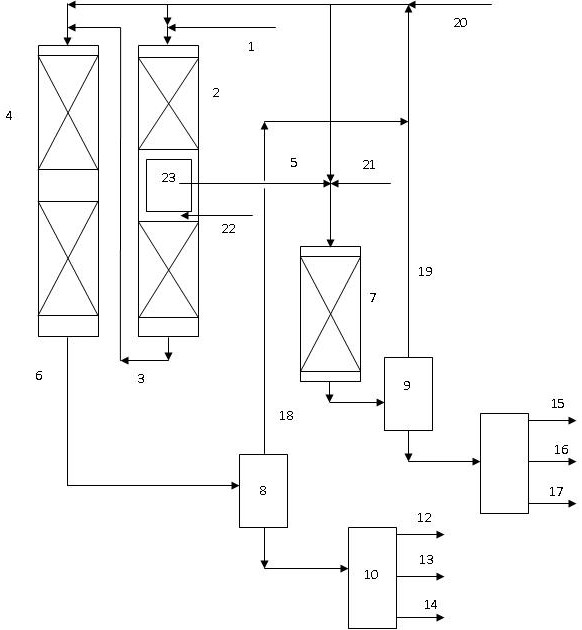

Method used

Image

Examples

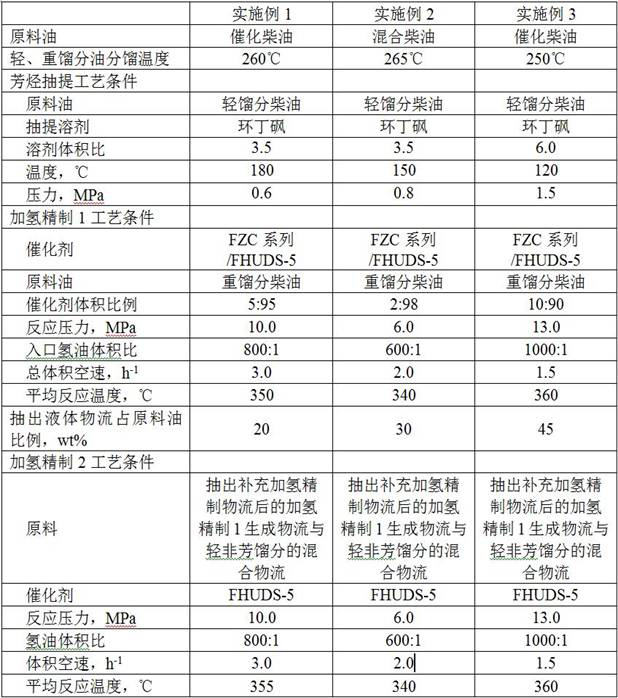

Embodiment 1-3

[0045] Protective agents FZC-100, FZC-105 and FZC106 are hydrogenation protective agents developed and produced by Fushun Petrochemical Research Institute of China Petrochemical Corporation; catalyst FHUDS-5 is developed and produced by Fushun Petrochemical Research Institute of China Petrochemical Corporation Hydrofining catalyst; Catalyst FHUDS-6 is a hydrofining catalyst developed and produced by Fushun Petrochemical Research Institute of China Petroleum & Chemical Corporation; Catalyst 3963 is a hydrorefining catalyst developed and produced by Fushun Petrochemical Research Institute of China Petroleum & Chemical Corporation Catalyst, containing Y type molecular sieve.

[0046] Table 1 Main properties of diesel feedstock oil

[0047] catalytic diesel Hybrid Diesel Density, g / cm 3

0.962 0.915 Distillation range, ℃ 165~375 150~400 Sulfur content, wt% 1.0 2.2 Nitrogen content, µg / g 950 460 cetane number 22 44 Aromatic con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com