Anti-corrosion material and preparation method and application thereof

A technology of anti-corrosion materials and anti-corrosion coatings, applied in the field of materials, can solve the problems of matrix fracture, damage, and corrosion-resistant alloys that cannot be repeatedly implemented, and achieve the effect of not damaging the matrix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

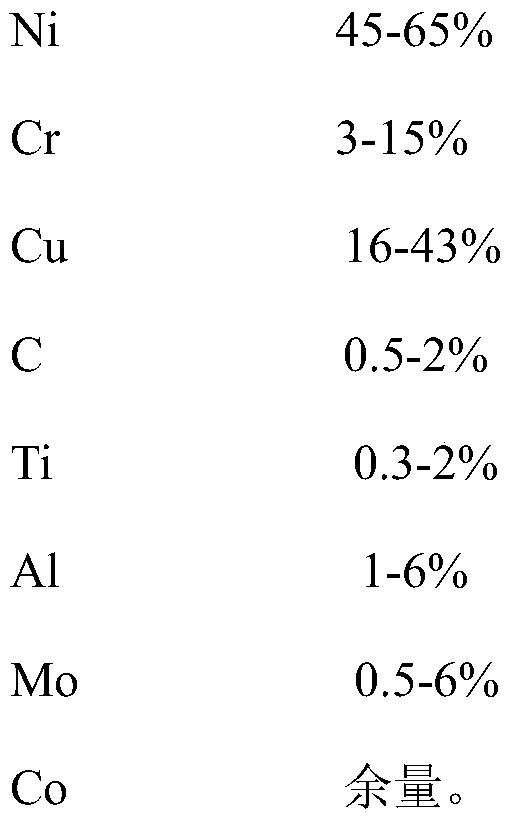

[0039] A kind of anti-corrosion material, by mass percentage, includes the following components:

[0040]

[0041] The anticorrosion material is a powdery anticorrosion material, and the mesh number of the anticorrosion material is 280 mesh.

[0042] A preparation method for an anti-corrosion material, comprising the following steps:

[0043] (1) Weigh each component according to the formula amount, mix thoroughly, and then put it into a vacuum furnace for melting at 1250° C. to obtain mixture A;

[0044] (2) Drying the mixture A prepared in step (1), and then performing solution treatment at 1000° C. to obtain mixture B;

[0045] (3) Water-quenching the mixture B prepared in step (2) to 30° C. and drying to obtain the anti-corrosion material.

[0046] The vacuum degree of the vacuum furnace in the step (1) is 10Pa, and the time of smelting is 35 minutes.

[0047] In step (2), the mixture A needs to be refined and atomized before being dried (the refining and atomizing a...

Embodiment 2

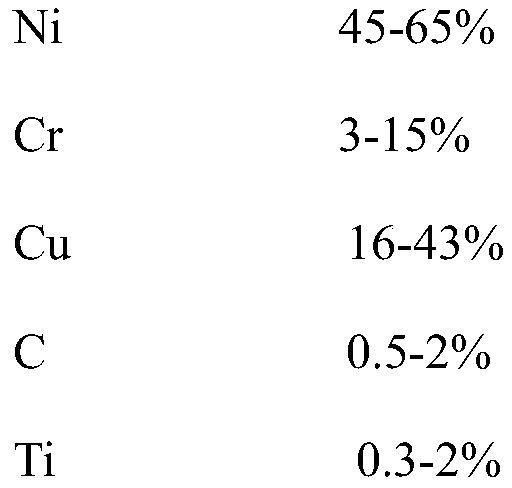

[0052] A kind of anti-corrosion material, by mass percentage, includes the following components:

[0053]

[0054] The anticorrosion material is a powdery anticorrosion material, and the mesh number of the anticorrosion material is 300 mesh.

[0055] A preparation method for an anti-corrosion material, comprising the following steps:

[0056] (1) Weigh each component according to the formula, fully mix, and then melt in a vacuum atomization furnace at 1350°C to obtain mixture A;

[0057] (2) Dry the mixture A prepared in step (1), and then carry out solution treatment at 1100° C. to obtain mixture B;

[0058] (3) The mixture B prepared in step (2) is water-quenched to 35° C. and dried to obtain the anti-corrosion material.

[0059] The vacuum degree of the vacuum furnace in the step (1) is 50Pa, and the time of smelting is 45 minutes.

[0060] In step (2), the mixture A needs to be refined and atomized before being dried (the refining and atomizing are conventional proce...

Embodiment 3

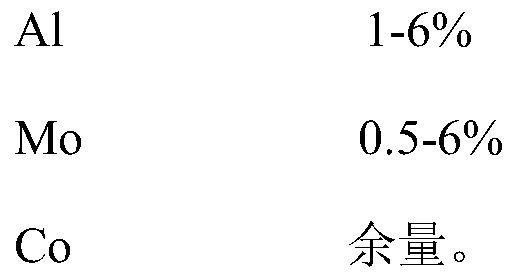

[0065] A kind of anti-corrosion material, by mass percentage, includes the following components:

[0066]

[0067] The anticorrosion material is a powdery anticorrosion material, and the mesh number of the anticorrosion material is 280 mesh.

[0068] A preparation method for an anti-corrosion material, comprising the following steps:

[0069] (1) Weigh each component according to the formula amount, mix thoroughly, and then put it into a vacuum furnace for melting at 1500° C. to obtain mixture A;

[0070] (2) Dry the mixture A prepared in step (1), and then carry out solution treatment at 1050° C. to obtain mixture B;

[0071] (3) Water quenching the mixture B prepared in step (2) to 40° C., then drying, and then performing a reduction reaction to obtain the anti-corrosion material.

[0072] The vacuum degree of the vacuum furnace in the step (1) is 80Pa, and the time of smelting is 45 minutes.

[0073] In step (2), the mixture A needs to be refined and atomized before b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com