Brewing method of high-freshness organic soy sauce

A high-freshness, organic technology, applied in food science and other directions, can solve the problem of insufficient umami of organic soy sauce, and achieve the effect of increasing salt-free solids, excellent color and flavor, and thick body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

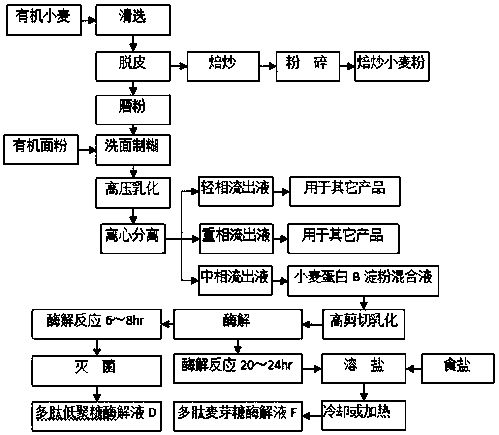

Method used

Image

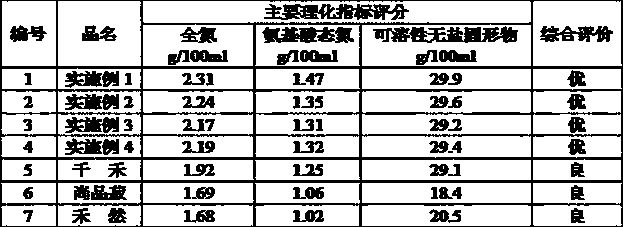

Examples

preparation Embodiment 1

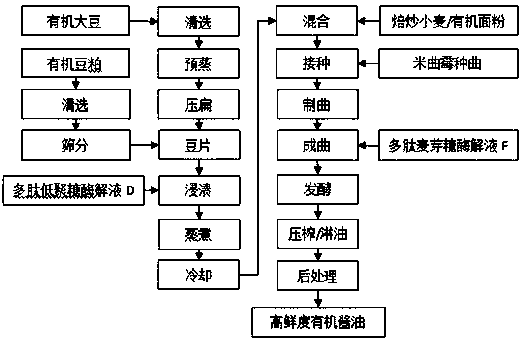

[0063] Japanese-style high-salt dilute mash fermentation preparation process using organic soybeans (hereinafter referred to as soybeans) and organic wheat (hereinafter referred to as wheat) as raw materials.

[0064] ① Main raw materials: soybean, wheat, salt, drinking water, wheat proteolytic enzyme [Nanning Donghenghuadao Biological Engineering Co., Ltd.], fungal α-amylase [Jining Hexin Biotechnology Co., Ltd.], aminopeptidase [Nanning Pangbo Bioengineering Co., Ltd.], cellulase [Nanning Donghenghuadao Bioengineering Co., Ltd.], soy sauce koji enzyme [made by Haoji Brewing Co., Ltd.], Aspergillus oryzae koji [made by Haoji Brewing Co., Ltd.]. (The same below).

[0065] ② First, the soybeans are screened, peeled, pre-steamed, and then pressed into soybean flakes for later use. The wheat is peeled and measured, and 20-40% of the soybean weight is taken, roasted at 180-350°C for 1-10 minutes, and the roasted wheat is cooled and crushed through a 32-mesh sieve for later use. ...

preparation Embodiment 2

[0072] The SB / T 10312 high-salt dilute state fermentation preparation process uses organic soybeans (hereinafter referred to as soybeans) and organic wheat flour (hereinafter referred to as flour) as raw materials.

[0073] ① Main raw materials: soybean, flour, salt, drinking water, wheat proteolytic enzyme, fungal α-amylase, aminopeptidase, cellulase, soy sauce koji, Aspergillus oryzae koji.

[0074] ② Screen the soybeans to remove impurities, peel them, pre-steam them and press them into flakes for later use, and sieve the flour for later use.

[0075] ③Take 1 to 1.2 times the weight of soybean flour, add 0.8 to 2 times the weight of the flour to wash the dough to make a paste, pass the batter through a high-pressure (100Bar) homogenizer for homogenization and aging, add 0.3 to 0.5 times of drinking water, and use a three-phase decanter Centrifuge for separation and collect the middle phase effluent (wheat protein and B starch mixture C).

[0076] ④ Add wheat protein and B ...

Embodiment 3

[0081] Using organic defatted soybeans (hereinafter referred to as soybean meal) and organic wheat (hereinafter referred to as wheat) as raw materials, Japanese-style high-salt dilute mash fermentation process.

[0082] ① Main raw materials: soybean meal, wheat, salt, drinking water, wheat proteolytic enzyme, fungal α-amylase, aminopeptidase, cellulase, soy sauce koji, Aspergillus oryzae koji.

[0083] ②Sieve the soybean meal to remove agglomerates and impurities. Dehulled wheat is measured, 20-40% of the weight of soybean meal is taken, roasted at 180-350°C for 1-10 minutes, and the roasted wheat is cooled and crushed through a 32-mesh sieve for later use.

[0084] ③ Take 1 to 1.2 times the weight of soybean meal and grind the wheat into flour. The fineness of the flour reaches 60 mesh or more, and then add 0.8 to 2 times the amount of drinking water to the wheat flour to wash the flour and make a batter; homogenize the batter through a high-pressure (100Bar) homogenizer Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com