Vomiting nursing device for digestive department

A nursing device and technology of gastroenterology, applied in the field of medical appliances, can solve the problems of reduced work intensity, poor load-bearing capacity of convenience bags, aggravated patient discomfort, etc., and achieve the effects of reducing work pressure, facilitating cleaning and processing, and reducing work pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The following is attached Figure 1-6 The present invention is described in further detail.

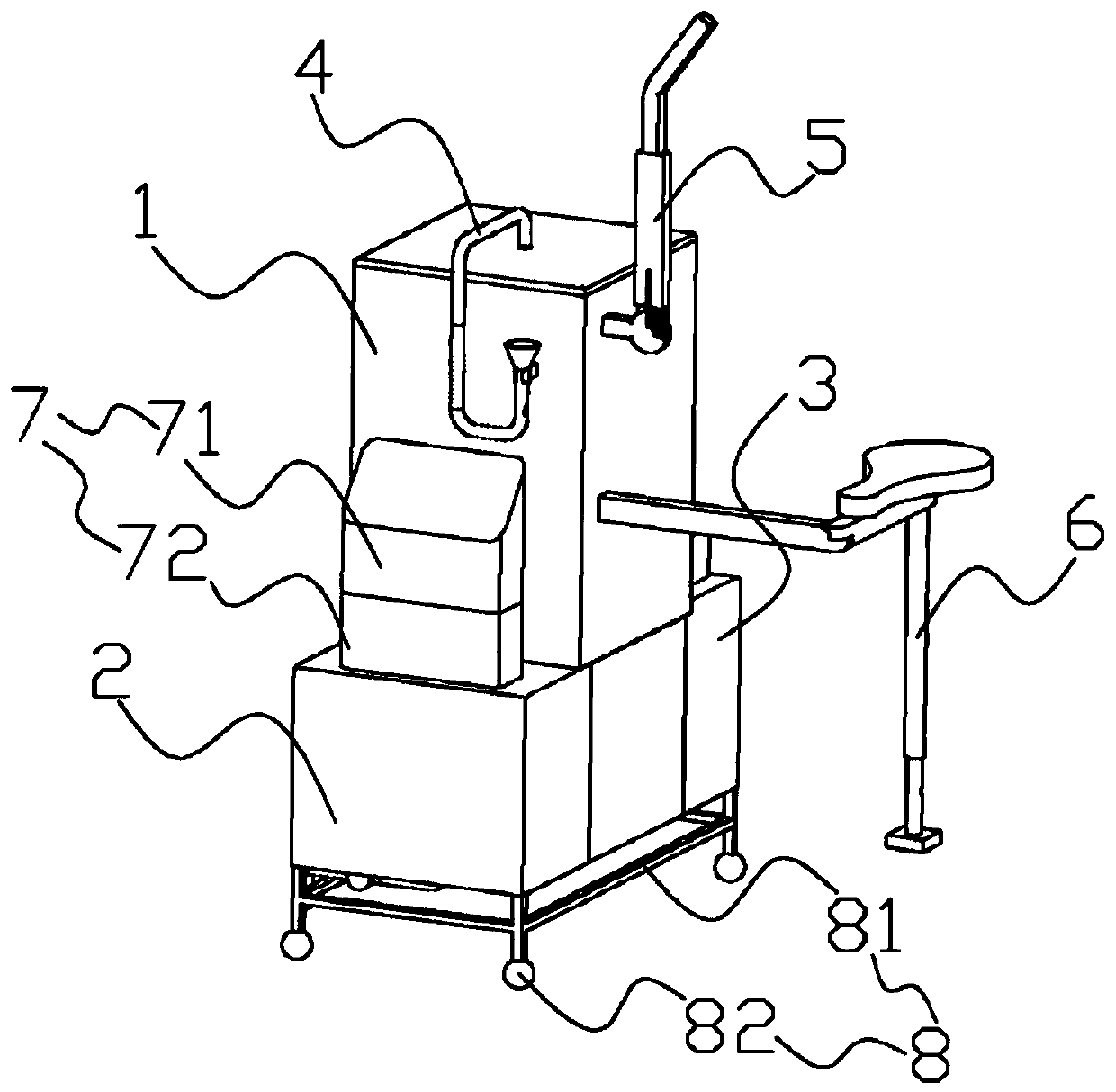

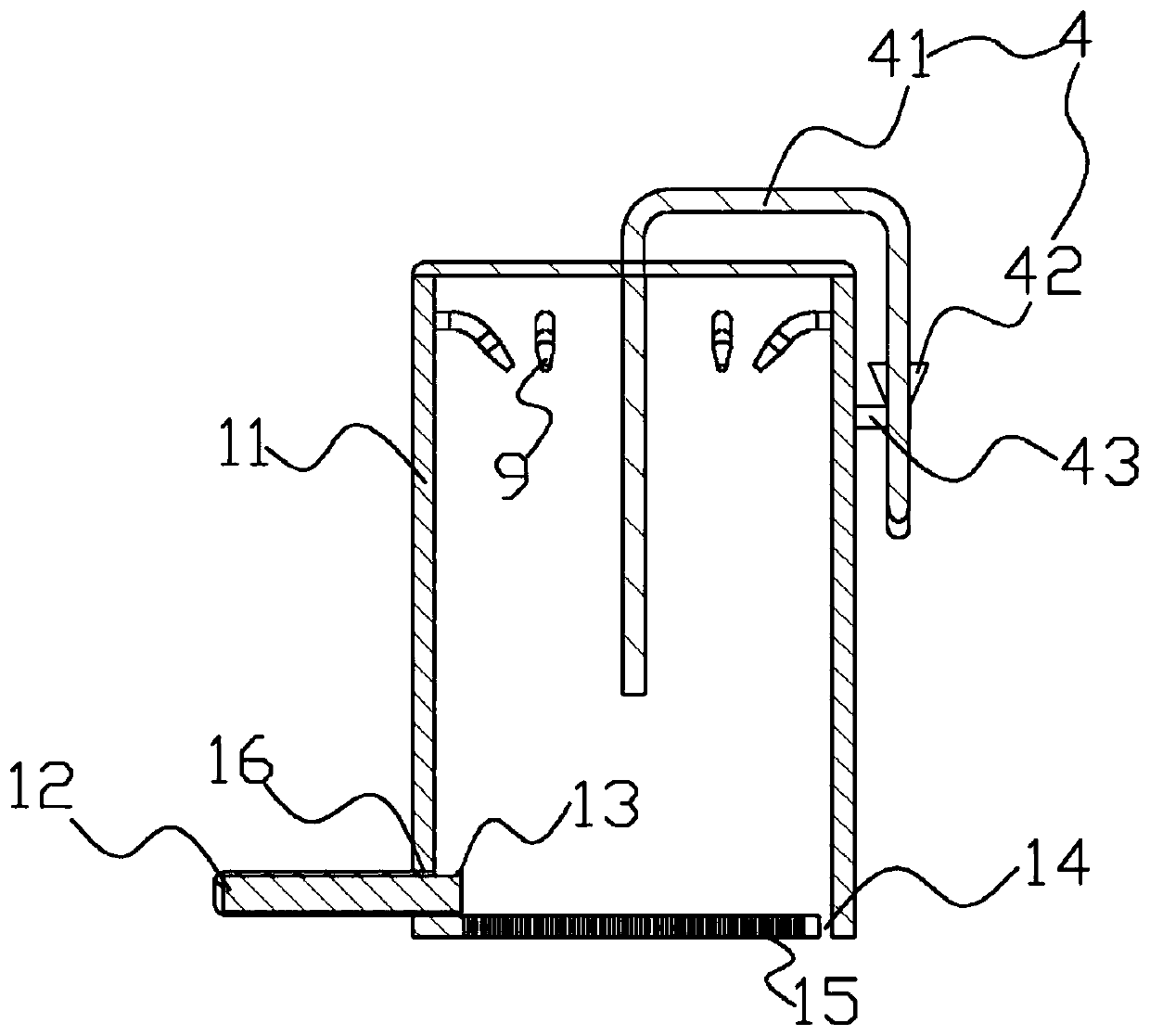

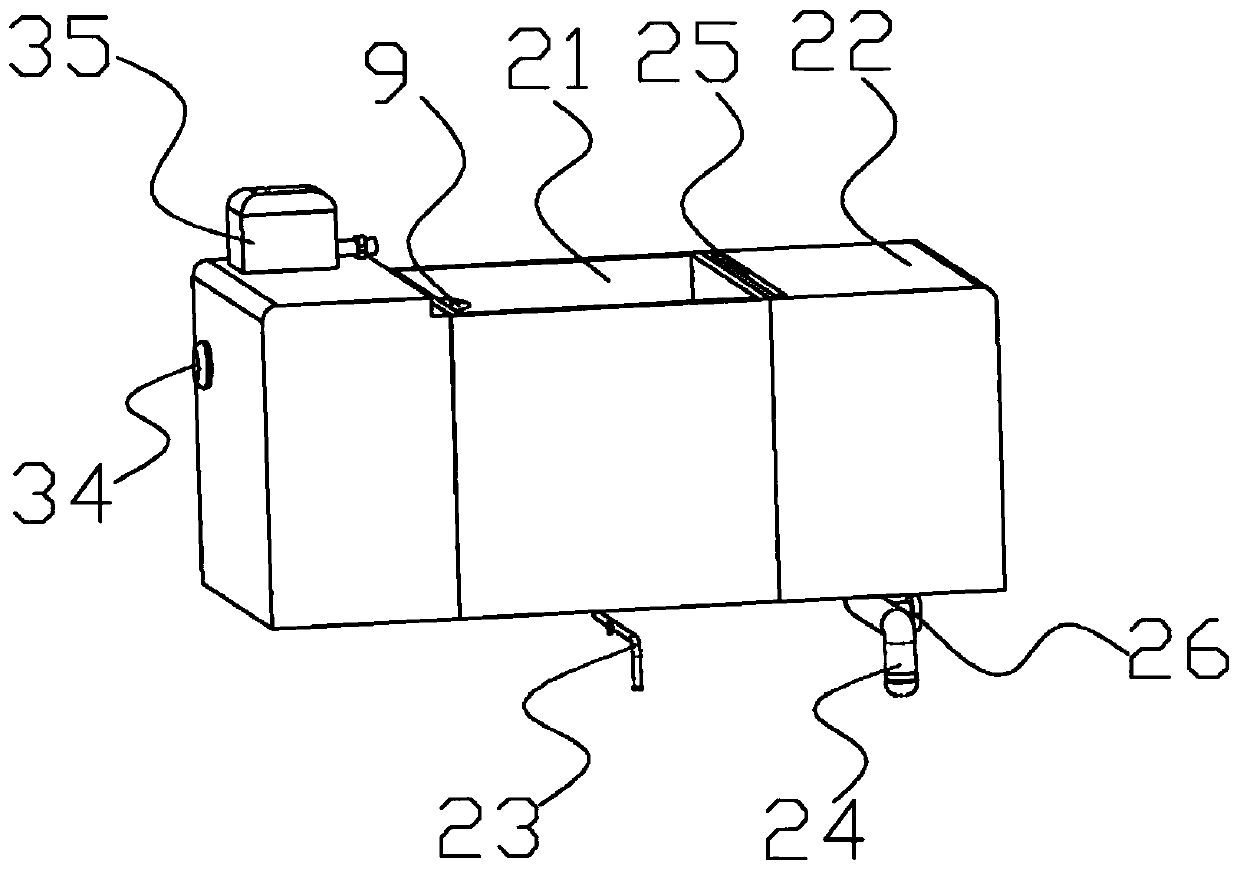

[0042] A gastroenterology vomiting care device, such as figure 1 and figure 2 As shown, it includes a classification processing unit 1, a vomitus storage unit 2, a liquid mixing unit 3, a conveying unit 4, a vomiting auxiliary unit 5, a seat unit 6, a control unit 7, and a traveling unit 8. The classification processing unit 1 is set in the vomitus storage unit. At the top of the part 2, the sorting processing part 1 communicates with the vomit container 2, and several nozzles 9 are arranged in the sorting processing part 1 and the vomit container 2, and the liquid mixing part 3 is arranged on the side of the vomit container 2, and the liquid mixing part 3 is connected to the vomit container 2. All nozzles 9 are connected by pipelines, and the conveying part 4 is arranged on the sorting processing part 1, and the vomiting auxiliary part 5 is arranged on the side of the sorti...

Embodiment 2

[0060] The difference from Example 1 is that the vomit container 2 is coated with an anti-corrosion layer, and the preparation method of the anti-corrosion layer is:

[0061] Take the following raw materials of each component by weight for later use: 21.6 parts of phenolic resin, 5.1 parts of polyetherimide, 2.3 parts of calcium carbonate powder, 3.9 parts of polyisocyanate, 4.8 parts of perchlorethylene, 9.2 parts of magnesium oxide powder, gas phase two 9 parts of silicon oxide, 24 parts of absolute ethanol.

[0062] (1) Add 24 parts of absolute ethanol into the dispersing tank, add 21.6 parts of phenolic resin, 3.9 parts of polyisocyanate, 5.1 parts of polyetherimide and 4.8 parts of perchlorethylene successively under stirring at 400r / min, and stir for 2 minutes ;

[0063] (2) After increasing the rotating speed to 720r / min, add 2.3 parts of calcium carbonate powder and 9.2 parts of magnesium oxide powder in turn, then increase the rotating speed to 900r / min and disperse ...

Embodiment 3

[0068] The difference from Example 2 is that the formula proportion of the anticorrosion layer has been modified, and the modified preparation method is:

[0069] Take the following raw materials of each component by weight for later use: 23.8 parts of phenolic resin, 5.5 parts of polyetherimide, 2.5 parts of calcium carbonate powder, 4.7 parts of polyisocyanate, 5.6 parts of perchlorethylene, 9.8 parts of magnesium oxide powder, gas phase two 10 parts of silicon oxide, 28 parts of absolute ethanol.

[0070] (1) Add 28 parts of absolute ethanol into the dispersing tank, add 23.8 parts of phenolic resin, 4.7 parts of polyisocyanate, 5.5 parts of polyetherimide and 5.6 parts of perchlorethylene successively under stirring at 400r / min, and stir for 2 minutes ;

[0071] (2) After increasing the rotating speed to 720r / min, add 2.5 parts of calcium carbonate powder and 9.8 parts of magnesium oxide powder in sequence, then increase the rotating speed to 900r / min and disperse for 15m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com