MoS2/schwertmannite Fenton composite catalyst, and preparation method and application thereof

A composite catalyst, a mannite-like Fenton technology, applied in physical/chemical process catalysts, chemical instruments and methods, special compound water treatment, etc. The effect of transferring, promoting the dissolution rate, and reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

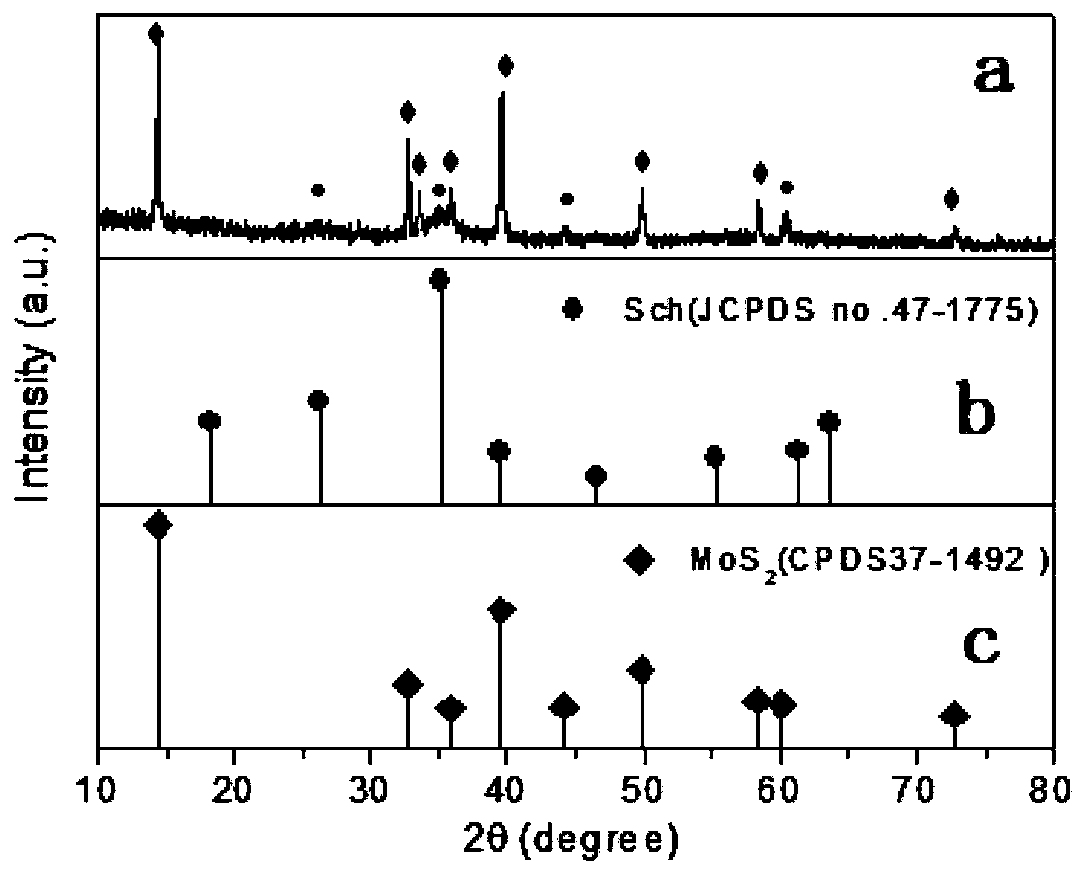

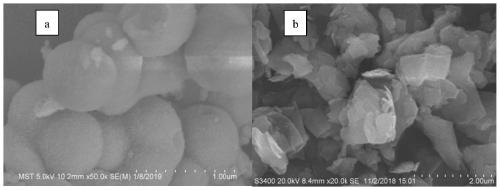

Image

Examples

Embodiment 1

[0040] MoS of this example 2 The preparation process of the Schwittmann stone-like Fenton composite catalyst comprises the following steps:

[0041] (1) Add 0.3g MoS to the Erlenmeyer flask 2 and ultrapure water, keeping the total reaction volume at 500mL, placed in an ultrasonic instrument for 5min to obtain MoS 2 the dispersion liquid;

[0042] (2) Use 1M H 2 SO 4 (or NaOH) to adjust the MoS 2 pH of the dispersion to 2.5;

[0043] (3) Add 11.12g FeSO 4 ·7H 2 O and 6mL H 2 o 2 (30w%), to obtain the mixed solution, the mixed solution is placed at 180r min -1 Shake culture in a reciprocating shaker for 24 hours at a culture temperature of 28°C to obtain a precipitate;

[0044] (4) The obtained precipitate was collected by filtration with a 0.45 μm filter membrane, washed with sulfuric acid solution (p H=2.0) and neutral deionized water (p H=6.8), rinsed three times respectively, and dried at constant temperature Dry in the box at 60°C and save the samples.

[0045]...

Embodiment 2

[0052] MoS of this example 2 The preparation process of the Schwittmann stone-like Fenton composite catalyst comprises the following steps:

[0053] (1) Add 0.5g MoS to the Erlenmeyer flask 2 and ultrapure water, keeping the total reaction volume at 500mL, placed in an ultrasonic instrument for 8 minutes to obtain MoS 2 the dispersion liquid;

[0054] (2) Use 1M H 2 SO 4 (or NaOH) to regulate MoS 2 The pH of the dispersion is 3.5;

[0055] (3) Add 11.12g FeSO 4 ·7H 2 O and 6 mL of H 2 o 2 (30w%); place the mixture at 180r·min -1 In a reciprocating shaker, the culture temperature is 28°C, and the culture is shaken for 24 hours;

[0056] (4) The precipitate obtained was collected by filtration with a 0.45 μm filter membrane, and the precipitate was washed with sulfuric acid solution (p H=2.0) and neutral deionized water (p H=6.8), washed three times respectively, and dried at constant temperature Dry in the box at 60°C and save the samples.

Embodiment 3

[0058] MoS of this example 2 The preparation process of the Schwittmann stone-like Fenton composite catalyst comprises the following steps:

[0059] (1) Add 0.1g MoS to the Erlenmeyer flask 2 and ultrapure water, keeping the total reaction volume at 500mL, placed in an ultrasonic instrument for 10min; to obtain MoS 2 the dispersion liquid;

[0060] (2) Use 1M H 2 SO 4 (or NaOH) to regulate MoS 2 The pH of the dispersion is 2.0;

[0061] (3) Add 11.12g FeSO 4 ·7H 2 O and 6mL H 2 o 2 (30w%); place the mixture at 180r·min -1 Shake culture in a reciprocating shaker for 24 hours at a culture temperature of 28°C to obtain a precipitate;

[0062] (4) The precipitate obtained was collected by filtration with a 0.45 μm filter membrane, and the precipitate was washed with sulfuric acid solution (p H=2.0) and neutral deionized water (p H=6.8), washed three times respectively, and dried at constant temperature Dry in the box at 60°C and save the samples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com